基本訊息

型號

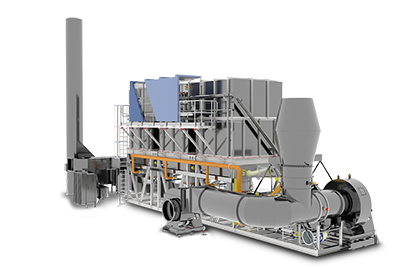

LC-RTO

Certification

ISO

Installation

Method

Horizontal

Operation

類型

Manually

Medium Material

Metal Fiber

Dust Collecting Method

Dry

Saving

1 M / h.;

Performance characteristics

The air volume of the treatment is from 2nm3 / h

Concentration ≥ 1000mg / m3

| Model | Air volume (m3/h); | 尺寸 (mm); | Burner(thousand Kcal); |

| LC-RTO -50 | 5000 | 5280*1790*3910 | 250 |

| LC-RTO -100 | 10000 | 6150*2380*4030 | 550 |

| LC-RTO -150 | 15000 | 7050*2830*4310 | 750 |

| LC-RTO -200 | 20000 | 7980*3150*4610 | 1000 |

| LC-RTO -300 | 30000 | 10650*4260*4950 | 1350 |

| LC-RTO -400 | 40000 | 12560*4720*5460 | 2000 |

| LC-RTO -500 | 50000 | 14200*5260*5860 | 2000 |

FAQ:;

Customer Question & Answer

If you have any questions,; please leave your valuable comments

Address: 316, No. 331, Chengnan Road, Lancheng Street, HangZhou City, ZheJiang Province

Business Type: Manufacturer/Factory

Business Range: Industrial Equipment & Components

Main Products: Waste Incineration Power Generation, Waste Incineration, Renergy Power Generation, Waste Incineration Power Plant, Refuse Incinerator, Energy

Company Introduction: HangZhou Lancheng Environmental Protection Technology Co., Ltd., located in HangZhou City, HangZhou City, ZheJiang Province, is a high-tech enterprise integrating scientific research, design, production and sales. The company strives for innovation with scientific research, survival with quality and development with reputation. With its professional level and mature technology in the field of environmental protection, it is rising rapidly. Customer satisfaction with products is our constant pursuit.

With a registered capital of 20 million yuan, the company has more than 2000 modern production bases in HangZhou Hong Kong Industrial Zone, HangZhou City, HangZhou City, ZheJiang Province. The company′s first-class environmental protection treatment designers have designed targeted treatment schemes from the aspects of system rationality, technological innovation and input-output economy for various complex working conditions, so as to make the emission indicators meet the national emission standards.

The company′s main products are: 1. Organic waste gas; Activated carbon, RTO, RCO, zeolite runner, dry filter box, etc. 2. Dust; Electrostatic precipitator, pulse bag filter and other equipment. 3. Pharmaceutical equipment; Drying equipment, mixing equipment, granulation equipment, crushing equipment. 4. Hot DIP galvanized wire. 5. Industrial wastewater treatment equipment, etc.

Our equipment has been successfully used in chemical industry, baking, coating, electroplating, waste incineration, printing, catering, municipal and other industries. At present, the company can formulate a perfect treatment scheme according to the current situation of enterprise sewage discharge, and use the existing patented technology to develop the most suitable products. We will provide you with the best quality solutions with the most advanced technology and the most sincere attitude.

The company always takes “carving carefully and creating high-quality products” as the enterprise purpose, and always takes “growing into the strongest environmental protection enterprise in Xihu (West Lake) Dis.” as the enterprise goal. In recent years, with the increasing attention of the state to environmental protection, “managing the atmosphere, beautifying the environment and benefiting mankind” has become our long-term task. In response to the call of the national “energy conservation and emission reduction” policy, blue city environmental protection company has made due contributions to revitalizing China′s environmental protection and building a harmonious society, and continues to strive to create a bluer sky and a better environment for us!

蓄熱式熱氧化器與催化氧化器相比如何?

蓄熱式熱氧化器 (RTO) 和催化氧化器都是用來控制工業製程空氣排放的有效技術。雖然它們的用途相似,但在操作、效率和適用性方面存在顯著差異。

以下是 RTO 和催化氧化劑之間的比較:

| 蓄熱式熱氧化器 (RTO) | 催化氧化劑 |

|---|---|

| 手術: | 手術: |

| RTO 透過高溫燃燒實現排放控制,無需使用催化劑。它們依賴熱氧化過程,其中廢氣中的 VOC 和其他污染物在高溫(通常在 1,400°F 至 1,600°F 之間)和過量氧氣存在的情況下被氧化。 | 與 RTO 相比,催化氧化劑利用催化劑(通常是貴金屬,例如鉑、鈀或銠)來促進 VOC 和其他污染物在較低溫度下的氧化。此催化劑降低了氧化反應所需的活化能,使其能夠在較低溫度(約 600°F 至 900°F)下發生。 |

| 效率: | 效率: |

| RTO 以其高熱效率而聞名。他們利用再生式熱交換器系統,將熱量從處理後的廢氣中回收並傳遞到進入的未處理氣體中,從而顯著降低燃料消耗。這種熱回收機制使 RTO 更加節能。 | 催化氧化器通常比 RTO 更節能,因為它們在較低的溫度下運作。催化劑促進氧化反應,使其在較低溫度下發生,從而減少加熱廢氣的能量需求。 |

| 適用性: | 適用性: |

| RTO 特別適合污染物濃度高或流量或污染物濃度變化較大的應用。它們通常用於控制化學製造、印刷、塗料和製藥等各行業的揮發性有機化合物 (VOC) 和有害空氣污染物 (HAP)。 | 在污染物濃度相對較低且相對恆定的應用中,通常優選催化氧化劑。它們對於汽車噴漆、印刷和食品加工等應用中的 VOC 控制非常有效,這些應用中 VOC 濃度可以更低且更一致。 |

| 限制: | 限制: |

| 由於其複雜的設計和熱回收系統,RTO 與催化氧化器相比具有更高的資本成本。它們還具有較高的工作溫度,這可能會限制它們在某些製程中的適用性或需要額外的熱回收系統。 | 催化氧化劑可能對廢氣中的毒物或污染物敏感,這些毒物或污染物會隨著時間的推移而使催化劑失去活性或降解。某些化合物,例如硫、有機矽或鹵代化合物,可能會毒害催化劑,降低其有效性並需要定期更換或再生催化劑。 |

在 RTO 和催化氧化器之間進行選擇時,必須考慮應用的特定要求,包括污染物濃度、流速、溫度要求和成本考量。諮詢環境工程專業人士或設備製造商可以協助確定最適合特定排放控制需求的技術。

Are regenerative thermal oxidizers suitable for controlling emissions from printing presses?

Yes, regenerative thermal oxidizers (RTOs) can be suitable for controlling emissions from printing presses. Printing presses can emit volatile organic compounds (VOCs) and other air pollutants during the printing process, which need to be properly controlled to comply with environmental regulations and ensure air quality. Here are some key points regarding the suitability of RTOs for controlling emissions from printing presses:

- Emission Control: RTOs are designed to achieve high destruction efficiencies for VOCs and hazardous air pollutants (HAPs). These pollutants are oxidized within the RTO at high temperatures, typically above 95% efficiency, converting them into carbon dioxide (CO2) and water vapor. RTOs effectively control and reduce emissions from printing presses.

- Compatibility: RTOs can be integrated into the exhaust system of printing presses, capturing and treating the emissions before they are released into the atmosphere. The RTO is typically connected to the exhaust stack of the printing press, allowing the VOC-laden air to pass through the oxidizer for treatment.

- High Flow Rates: Printing presses can generate significant exhaust volumes due to the printing process. RTOs are designed to handle high flow rates and can accommodate the varying exhaust volumes of printing presses. This ensures effective treatment of emissions even during peak production periods.

- Thermal Capacity: RTOs have the thermal capacity to handle the temperature variations in printing press emissions. The printing process can result in varying exhaust temperatures, and RTOs are designed to operate effectively within a wide range of temperature conditions.

- Energy Efficiency: RTOs incorporate heat exchange systems that allow for the recovery and reuse of thermal energy. The heat exchangers within the RTO capture the heat from the outgoing exhaust gases and transfer it to the incoming process air or gas stream. This heat recovery process improves the overall energy efficiency of the system and reduces the need for additional fuel consumption.

- Compliance with Regulations: Printing press emissions are subject to regulatory requirements for air quality and emissions control. RTOs are capable of achieving the necessary destruction efficiencies and can help printing press operators comply with environmental regulations. The use of RTOs demonstrates a commitment to sustainable practices and responsible management of air emissions.

It is important to note that the specific design and configuration of the RTO, as well as the characteristics of the printing press emissions, should be considered when implementing an RTO for a printing press application. Consulting with experienced engineers or RTO manufacturers can provide valuable insights into the proper sizing, integration, and performance requirements for controlling emissions from printing presses.

In summary, RTOs are a suitable technology for controlling emissions from printing presses, providing high destruction efficiencies, compatibility with printing press exhaust systems, handling high flow rates and temperature variations, energy efficiency through heat recovery, and compliance with environmental regulations.

How efficient are regenerative thermal oxidizers in destroying volatile organic compounds (VOCs)?

Regenerative thermal oxidizers (RTOs) are highly efficient in destroying volatile organic compounds (VOCs) emitted from industrial processes. Here are the reasons why RTOs are considered efficient in VOC destruction:

1. High Destruction Efficiency: RTOs are known for their high destruction efficiency, typically exceeding 99%. They effectively oxidize VOCs present in the industrial exhaust streams, converting them into less harmful byproducts, such as carbon dioxide and water vapor. This high destruction efficiency ensures that the majority of VOCs are eliminated, resulting in cleaner emissions and compliance with environmental regulations.

2. Residence Time: RTOs provide a sufficiently long residence time for the combustion of VOCs. In the RTO chamber, the VOC-laden air is directed through a ceramic media bed, which acts as a heat sink. The VOCs are heated to the combustion temperature and react with the available oxygen, leading to their destruction. The design of RTOs ensures that the VOCs have ample time to undergo complete combustion before being released into the atmosphere.

3. Temperature Control: RTOs maintain the combustion temperature within a specific range to optimize VOC destruction. The operating temperature is carefully controlled based on factors such as the type of VOCs, their concentration, and the specific requirements of the industrial process. By controlling the temperature, RTOs ensure that the VOCs are efficiently oxidized, maximizing destruction efficiency while minimizing the formation of harmful byproducts, such as nitrogen oxides (NOx).

4. Heat Recovery: RTOs incorporate a regenerative heat recovery system, which enhances their overall energy efficiency. The system captures and preheats the incoming process air by utilizing the heat energy from the outgoing exhaust stream. This heat recovery mechanism minimizes the amount of external fuel required to sustain the combustion temperature, resulting in energy savings and cost-effectiveness. The heat recovery also helps maintain the high destruction efficiency of VOCs by providing a consistent and optimized operating temperature.

5. Catalyst Integration: In some cases, RTOs can be equipped with catalyst beds to further enhance VOC destruction efficiency. Catalysts can accelerate the oxidation process and lower the required operating temperature, improving the overall efficiency of VOC destruction. Catalyst integration is particularly beneficial for processes with lower VOC concentrations or when specific VOCs require lower temperatures for effective oxidation.

6. Compliance with Regulations: The high destruction efficiency of RTOs ensures compliance with environmental regulations governing VOC emissions. Many industrial sectors are subject to stringent air quality standards and emission limits. RTOs provide an effective solution for meeting these requirements by reliably and efficiently destroying VOCs, reducing their impact on air quality and public health.

In summary, regenerative thermal oxidizers (RTOs) are highly efficient in destroying volatile organic compounds (VOCs). Their high destruction efficiency, residence time, temperature control, heat recovery capabilities, optional catalyst integration, and compliance with regulations make RTOs a preferred choice for industries seeking effective and sustainable solutions for VOC abatement.

editor by CX 2023-08-31