Maklumat Asas.

Model NO.

RTO

Kaedah Pemprosesan

Pembakaran

Punca Tarikan

Kawalan Pencemaran Udara

Tanda dagangan

RUIMA

asal usul

China

Kod HS

84213990

Penerangan Produk

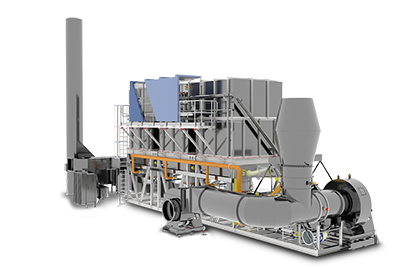

Pengoksida Terma Penjanaan Semula (RTO);

Teknik pengoksidaan yang paling banyak digunakan pada masa kini untuk

Pengurangan pelepasan VOC,; sesuai untuk merawat pelbagai pelarut dan proses.; Bergantung pada isipadu udara dan kecekapan penulenan yang diperlukan,; RTO datang dengan 2,; 3,; 5 atau 10 bilik.;

Kelebihan

Pelbagai VOC untuk dirawat

Kos penyelenggaraan yang rendah

Kecekapan Terma Tinggi

Tidak menjana sebarang pembaziran

Boleh disesuaikan untuk kecil,; aliran udara sederhana dan besar

Pemulihan Haba melalui pintasan jika kepekatan VOC melebihi titik auto-terma

Auto-terma dan Pemulihan Haba:;

Kecekapan Terma > 95%

Titik auto-terma pada 1.;2 – 1.;7 mgC/Nm3

Julat aliran udara dari 2,; 000 hingga 200,; 000m3/j

Kemusnahan VOC yang tinggi

Kecekapan penulenan biasanya melebihi 99%

Address: No 3 North Xihu (West Lake) Dis. Road, Xihu (West Lake) Dis., HangZhou, ZheJiang , China

Business Type: Manufacturer/Factory

Business Range: Manufacturing & Processing Machinery, Service

Management System Certification: ISO 14001, ISO 9001, OHSAS/ OHSMS 18001, QHSE

Main Products: Dryer, Extruder, Heater, Twin Screw Extruder, Electrochemical Corrosion Protection Equ, Screw, Mixer, Pelletizing Machine, Compressor, Pelletizer

Company Introduction: The Res. Inst of Chem. Mach of the Ministry of Chemical Industry was founded in ZheJiang in 1958, and moved to HangZhou in 1965.

The Res. Inst of Automation Kementerian Industri Kimia telah diasaskan di HangZhou pada tahun 1963.

Pada tahun 1997, Res. Inst. Daripada Chem. Mach Kementerian Industri Kimia dan Res. Inst. Automasi Kementerian Industri Kimia telah digabungkan untuk menjadi Res. Inst of Chemical Machinery and Automation of Kementerian Industri Kimia.

Pada tahun 2000, Res. Inst of Chemical Machinery and Automation of Ministry of ChemicalIndustry menyelesaikan transformasinya kepada perusahaan dan didaftarkan sebagai CHINAMFG Instituteof Chemical Machinery and Automation.

Institut Tianhua mempunyai institusi subordinat berikut:

Pusat Penyeliaan dan Pemeriksaan Kualiti Peralatan Kimia di HangZhou, Wilayah ZheJiang

Institut Peralatan HangZhou di HangZhou, Wilayah ZheJiang;

Institut Automasi di HangZhou, Wilayah ZheJiang;

HangZhou Ruima Chemical Machinery Co Ltd di HangZhou, Wilayah ZheJiang;

HangZhou Ruide Drying Technology Co Ltd di HangZhou, Wilayah ZheJiang;

HangZhouLantai Plastics Machinery Co Ltd di HangZhou, Wilayah ZheJiang;

ZheJiang Airuike Automation Technology Co Ltd di HangZhou, Wilayah ZheJiang;

Institut Jentera Kimia dan automasi HangZhou United dan Institut Relau Industri Petrokimia HangZhou United diasaskan oleh Institut CHINAMFG dan Sinopec.

Institut Tianhua mempunyai kawasan pekerjaan seluas 80 000m2 dan jumlah aset 1 Yuan (RMB). Nilai keluaran tahunan ialah 1 Yuan (RMB).

Institut Tianhua mempunyai kira-kira 916 pekerja, 75% daripada mereka adalah kakitangan profesional. Antaranya ialah 23 profesor, 249jurutera kanan, 226 jurutera. 29 profesor dan jurutera kanan menikmati subsidi khas negara, Kepada 5 orang gelaran Pakar Pertengahan Umur dan Muda dengan Sumbangan Cemerlang kepada RR China dianugerahkan

Bagaimanakah pengoksida terma regeneratif dibandingkan dengan pengoksida pemangkin?

Pengoksida terma regeneratif (RTO) dan pengoksida pemangkin adalah kedua-dua teknologi berkesan yang digunakan untuk mengawal pelepasan udara daripada proses perindustrian. Walaupun ia mempunyai tujuan yang sama, terdapat perbezaan yang ketara dalam operasi, kecekapan dan kebolehgunaannya.

Berikut ialah perbandingan antara RTO dan pengoksida pemangkin:

| Pengoksida Terma Regeneratif (RTO) | Pengoksida Bermangkin |

|---|---|

| Operasi: | Operasi: |

| RTO mencapai kawalan pelepasan melalui pembakaran suhu tinggi tanpa menggunakan pemangkin. Mereka bergantung pada proses pengoksidaan terma, di mana VOC dan bahan pencemar lain dalam gas ekzos teroksida pada suhu tinggi (biasanya antara 1,400°F dan 1,600°F) dengan kehadiran oksigen berlebihan. | Pengoksida pemangkin menggunakan mangkin (biasanya logam berharga, seperti platinum, paladium, atau rhodium) untuk memudahkan pengoksidaan VOC dan bahan pencemar lain pada suhu yang lebih rendah berbanding dengan RTO. Mangkin merendahkan tenaga pengaktifan yang diperlukan untuk tindak balas pengoksidaan, membolehkannya berlaku pada suhu yang lebih rendah (sekitar 600°F hingga 900°F). |

| Kecekapan: | Kecekapan: |

| RTO terkenal dengan kecekapan haba yang tinggi. Mereka menggunakan sistem penukar haba regeneratif yang memulihkan dan memindahkan haba daripada gas ekzos yang dirawat kepada gas yang tidak dirawat yang masuk, dengan ketara mengurangkan penggunaan bahan api. Mekanisme pemulihan haba ini menjadikan RTO cekap tenaga. | Pengoksida pemangkin biasanya lebih cekap tenaga daripada RTO kerana ia beroperasi pada suhu yang lebih rendah. Mangkin memudahkan tindak balas pengoksidaan, membolehkan ia berlaku pada suhu yang lebih rendah, yang mengurangkan keperluan tenaga untuk memanaskan gas ekzos. |

| Kebolehgunaan: | Kebolehgunaan: |

| RTO amat sesuai untuk aplikasi di mana kepekatan pencemar adalah tinggi, atau di mana terdapat variasi yang luas dalam kadar aliran atau kepekatan pencemar. Ia biasanya digunakan untuk mengawal sebatian organik meruap (VOC) dan bahan pencemar udara berbahaya (HAP) dalam pelbagai industri, termasuk pembuatan kimia, percetakan, salutan dan farmaseutikal. | Pengoksida pemangkin selalunya diutamakan dalam aplikasi di mana kepekatan pencemar adalah agak rendah dan agak malar. Ia berkesan untuk kawalan VOC dalam aplikasi seperti pengecatan automotif, percetakan, dan pemprosesan makanan, di mana kepekatan VOC boleh lebih rendah dan lebih konsisten. |

| Had: | Had: |

| RTO mempunyai kos modal yang lebih tinggi berbanding dengan pengoksida pemangkin kerana reka bentuk yang kompleks dan sistem pemulihan haba. Ia juga mempunyai suhu operasi yang lebih tinggi, yang mungkin mengehadkan kebolehgunaannya dalam proses tertentu atau memerlukan sistem pemulihan haba tambahan. | Pengoksida pemangkin boleh menjadi sensitif kepada racun atau bahan cemar dalam gas ekzos yang boleh menyahaktifkan atau merendahkan mangkin dari semasa ke semasa. Sebatian tertentu, seperti sulfur, silikon atau sebatian halogen, berpotensi meracuni mangkin, mengurangkan keberkesanannya dan memerlukan penggantian atau penjanaan semula mangkin secara berkala. |

Apabila memilih antara RTO dan pengoksida pemangkin, adalah penting untuk mempertimbangkan keperluan khusus aplikasi, termasuk kepekatan pencemar, kadar aliran, keperluan suhu dan pertimbangan kos. Berunding dengan profesional kejuruteraan alam sekitar atau pengeluar peralatan boleh membantu menentukan teknologi yang paling sesuai untuk keperluan kawalan pelepasan tertentu.

Are regenerative thermal oxidizers suitable for controlling emissions from printing presses?

Yes, regenerative thermal oxidizers (RTOs) can be suitable for controlling emissions from printing presses. Printing presses can emit volatile organic compounds (VOCs) and other air pollutants during the printing process, which need to be properly controlled to comply with environmental regulations and ensure air quality. Here are some key points regarding the suitability of RTOs for controlling emissions from printing presses:

- Kawalan pelepasan: RTOs are designed to achieve high destruction efficiencies for VOCs and hazardous air pollutants (HAPs). These pollutants are oxidized within the RTO at high temperatures, typically above 95% efficiency, converting them into carbon dioxide (CO2) and water vapor. RTOs effectively control and reduce emissions from printing presses.

- Compatibility: RTOs can be integrated into the exhaust system of printing presses, capturing and treating the emissions before they are released into the atmosphere. The RTO is typically connected to the exhaust stack of the printing press, allowing the VOC-laden air to pass through the oxidizer for treatment.

- High Flow Rates: Printing presses can generate significant exhaust volumes due to the printing process. RTOs are designed to handle high flow rates and can accommodate the varying exhaust volumes of printing presses. This ensures effective treatment of emissions even during peak production periods.

- Kapasiti Terma: RTOs have the thermal capacity to handle the temperature variations in printing press emissions. The printing process can result in varying exhaust temperatures, and RTOs are designed to operate effectively within a wide range of temperature conditions.

- Energy Efficiency: RTO menggabungkan sistem pertukaran haba yang membolehkan pemulihan dan penggunaan semula tenaga haba. Penukar haba dalam RTO menangkap haba daripada gas ekzos yang keluar dan memindahkannya ke aliran udara atau gas proses masuk. Proses pemulihan haba ini meningkatkan kecekapan tenaga keseluruhan sistem dan mengurangkan keperluan untuk penggunaan bahan api tambahan.

- Pematuhan dengan Peraturan: Printing press emissions are subject to regulatory requirements for air quality and emissions control. RTOs are capable of achieving the necessary destruction efficiencies and can help printing press operators comply with environmental regulations. The use of RTOs demonstrates a commitment to sustainable practices and responsible management of air emissions.

It is important to note that the specific design and configuration of the RTO, as well as the characteristics of the printing press emissions, should be considered when implementing an RTO for a printing press application. Consulting with experienced engineers or RTO manufacturers can provide valuable insights into the proper sizing, integration, and performance requirements for controlling emissions from printing presses.

In summary, RTOs are a suitable technology for controlling emissions from printing presses, providing high destruction efficiencies, compatibility with printing press exhaust systems, handling high flow rates and temperature variations, energy efficiency through heat recovery, and compliance with environmental regulations.

Apakah pengoksida terma regeneratif?

Pengoksida terma regeneratif (RTO) ialah peranti kawalan pencemaran udara termaju yang digunakan dalam aplikasi industri untuk membuang sebatian organik meruap (VOC), bahan cemar udara berbahaya (HAP) dan bahan cemar bawaan udara lain daripada gas ekzos. Ia beroperasi dengan menggunakan suhu tinggi untuk mengurai atau mengoksidakan bahan pencemar secara terma, menukarkannya kepada produk sampingan yang kurang berbahaya.

Bagaimanakah pengoksida terma regeneratif berfungsi?

RTO terdiri daripada beberapa komponen utama dan beroperasi melalui proses kitaran:

1. Plenum Masuk: Gas ekzos yang mengandungi bahan pencemar memasuki RTO melalui plenum masuk.

2. Katil Penukar Haba: RTO mengandungi berbilang katil penukar haba yang diisi dengan media penyimpanan haba, biasanya bahan seramik atau pembungkusan berstruktur. Katil penukar haba disusun secara berpasangan.

3. Injap Kawalan Aliran: Injap kawalan aliran mengarahkan aliran udara dan mengawal arah gas ekzos melalui RTO.

4. Kebuk Pembakaran: Gas ekzos, kini diarahkan ke dalam kebuk pembakaran, dipanaskan pada suhu tinggi, biasanya antara 1400°F (760°C) dan 1600°F (870°C). Julat suhu ini memastikan pengoksidaan haba yang berkesan bagi bahan pencemar.

5. Kemusnahan VOC: Suhu tinggi dalam kebuk pembakaran menyebabkan VOC dan bahan cemar lain bertindak balas dengan oksigen, mengakibatkan penguraian haba atau pengoksidaan. Proses ini memecahkan bahan pencemar kepada wap air, karbon dioksida, dan gas tidak berbahaya yang lain.

6. Pemulihan Haba: Gas-gas panas dan tulen yang meninggalkan kebuk pembakaran melalui plenum alir keluar dan mengalir melalui katil penukar haba yang berada dalam fasa operasi yang bertentangan. Media penyimpanan haba di dalam katil menyerap haba daripada gas yang keluar, yang memanaskan gas ekzos yang masuk.

7. Penukaran Kitaran: Selepas selang masa tertentu, injap kawalan aliran menukar arah aliran udara, membenarkan katil penukar haba yang memanaskan gas masuk kini menerima gas panas daripada kebuk pembakaran. Kitaran kemudian berulang, memastikan operasi berterusan dan cekap.

Kelebihan pengoksida terma regeneratif:

RTO menawarkan beberapa kelebihan dalam kawalan pencemaran udara industri:

1. Kecekapan Tinggi: RTO boleh mencapai kecekapan pemusnahan yang tinggi, biasanya melebihi 95%, dengan berkesan menyingkirkan pelbagai jenis bahan pencemar.

2. Pemulihan Tenaga: Mekanisme pemulihan haba dalam RTO membolehkan penjimatan tenaga yang ketara. Pemanasan awal gas yang masuk mengurangkan penggunaan bahan api yang diperlukan untuk pembakaran, menjadikan RTO cekap tenaga.

3. Keberkesanan kos: Walaupun pelaburan modal awal untuk RTO boleh menjadi ketara, penjimatan kos operasi jangka panjang melalui pemulihan tenaga dan kecekapan pemusnahan yang tinggi menjadikannya penyelesaian yang kos efektif sepanjang jangka hayat sistem.

4. Pematuhan Alam Sekitar: RTO direka bentuk untuk memenuhi peraturan pelepasan yang ketat dan membantu industri mematuhi piawaian dan permit kualiti udara.

5. serba boleh: RTO boleh mengendalikan pelbagai volum ekzos proses dan kepekatan pencemar, menjadikannya sesuai untuk pelbagai aplikasi perindustrian.

Secara keseluruhannya, pengoksida terma regeneratif adalah peranti kawalan pencemaran udara yang sangat cekap dan berkesan digunakan secara meluas dalam industri untuk meminimumkan pelepasan dan memastikan pematuhan alam sekitar.

editor by CX 2024-01-30