معلومات اساسية.

نموذج رقم.

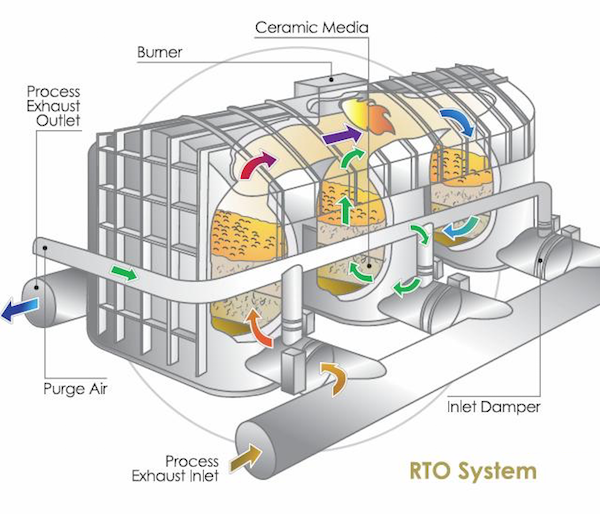

LC-RTO

Certification

ISO

Installation

Method

Horizontal

Operation

يكتب

Manually

Medium Material

Metal Fiber

Dust Collecting Method

Dry

Saving

1 M / h.;

خصائص الأداء

حجم الهواء للمعالجة من 2nm3/h

التركيز ≥ 1000 ملغم / م3

| Model | Air volume (m3/h); | مقاس (mm); | Burner(thousand Kcal); |

| LC-RTO -50 | 5000 | 5280*1790*3910 | 250 |

| LC-RTO -100 | 10000 | 6150*2380*4030 | 550 |

| LC-RTO -150 | 15000 | 7050*2830*4310 | 750 |

| LC-RTO -200 | 20000 | 7980*3150*4610 | 1000 |

| LC-RTO -300 | 30000 | 10650*4260*4950 | 1350 |

| LC-RTO -400 | 40000 | 12560*4720*5460 | 2000 |

| LC-RTO -500 | 50000 | 14200*5260*5860 | 2000 |

FAQ:;

أسئلة وأجوبة العملاء

إذا كان لديك أي أسئلة، يرجى ترك تعليقاتك القيمة

العنوان: 316، رقم 331، طريق تشنغنان، شارع لانتشنغ، مدينة هانغتشو، مقاطعة تشجيانغ

نوع العمل: مصنع/شركة مصنعة

نطاق العمل: المعدات والمكونات الصناعية

المنتجات الرئيسية: توليد الطاقة من حرق النفايات، حرق النفايات، توليد الطاقة المتجددة، محطة توليد الطاقة من حرق النفايات، محرقة النفايات، الطاقة

مقدمة عن الشركة: شركة HangZhou Lancheng Environmental Protection Technology المحدودة، التي تقع في مدينة HangZhou، مدينة HangZhou، مقاطعة ZheJiang، هي شركة ذات تكنولوجيا عالية تجمع بين البحث العلمي والتصميم والإنتاج والمبيعات. تسعى الشركة إلى الابتكار من خلال البحث العلمي، والبقاء من خلال الجودة والتطوير من خلال السمعة. بفضل مستواها المهني وتقنيتها الناضجة في مجال حماية البيئة، فإنها ترتفع بسرعة. رضا العملاء عن المنتجات هو هدفنا الدائم.

برأس مال مسجل يبلغ 20 مليون يوان، تمتلك الشركة أكثر من 2000 قاعدة إنتاج حديثة في منطقة هانغتشو هونغ كونغ الصناعية، مدينة هانغتشو، مدينة هانغتشو، مقاطعة تشجيانغ. وقد صمم مصممو المعالجة البيئية من الدرجة الأولى في الشركة مخططات معالجة مستهدفة من جوانب عقلانية النظام والابتكار التكنولوجي واقتصاد المدخلات والمخرجات لمختلف ظروف العمل المعقدة، وذلك لجعل مؤشرات الانبعاثات تلبي معايير الانبعاثات الوطنية.

المنتجات الرئيسية للشركة هي: 1. غاز النفايات العضوية؛ الكربون المنشط، RTO، RCO، عداء الزيوليت، صندوق الفلتر الجاف، إلخ. 2. الغبار؛ المرسب الكهروستاتيكي، مرشح كيس النبض وغيرها من المعدات. 3. المعدات الصيدلانية؛ معدات التجفيف، معدات الخلط، معدات التحبيب، معدات التكسير. 4. الأسلاك المجلفنة بالغمس الساخن. 5. معدات معالجة مياه الصرف الصناعي، إلخ.

تم استخدام معداتنا بنجاح في الصناعة الكيميائية، والخبز، والطلاء، والطلاء الكهربائي، وحرق النفايات، والطباعة، والمطاعم، والبلديات وغيرها من الصناعات. في الوقت الحاضر، يمكن للشركة صياغة مخطط معالجة مثالي وفقًا للوضع الحالي لتصريف مياه الصرف الصحي في المؤسسة، واستخدام التكنولوجيا الحاصلة على براءة اختراع الحالية لتطوير المنتجات الأكثر ملاءمة. سنقدم لك أفضل الحلول ذات الجودة مع أحدث التقنيات وأكثر المواقف صدقًا.

تتخذ الشركة دائمًا "النحت بعناية وإنشاء منتجات عالية الجودة" كغرض للمؤسسة، وتتخذ دائمًا "النمو إلى أقوى مؤسسة لحماية البيئة في منطقة شيهو (بحيرة الغرب)" كهدف للمؤسسة. في السنوات الأخيرة، مع الاهتمام المتزايد من الدولة بحماية البيئة، أصبحت "إدارة الغلاف الجوي وتجميل البيئة وإفادة البشرية" مهمتنا طويلة الأمد. استجابة لدعوة سياسة "الحفاظ على الطاقة والحد من الانبعاثات" الوطنية، قدمت شركة حماية البيئة في المدينة الزرقاء مساهمات مناسبة لإحياء حماية البيئة في الصين وبناء مجتمع متناغم، وتواصل السعي لخلق سماء أكثر زرقة وبيئة أفضل لنا!

Are regenerative thermal oxidizers suitable for controlling particulate matter emissions?

Regenerative thermal oxidizers (RTOs) are primarily designed for the destruction of volatile organic compounds (VOCs) and hazardous air pollutants (HAPs). While RTOs are highly effective in treating gaseous pollutants, they are not specifically designed for controlling particulate matter emissions.

Here are some key points to consider regarding the suitability of RTOs for controlling particulate matter emissions:

- Particulate Matter (PM) Removal Mechanism: RTOs primarily operate based on the thermal oxidation of pollutants. They rely on high temperatures to break down and destroy gaseous pollutants, but they do not have a dedicated mechanism for capturing and removing particulate matter. The design of RTOs does not incorporate features such as filters or electrostatic precipitators that are commonly used for effective particulate matter control.

- Limited Particulate Matter Destruction: While RTOs can provide some incidental removal of fine particulate matter through mechanisms like thermal decomposition and agglomeration, the removal efficiency for particulate matter is generally low compared to dedicated particulate control devices. The focus of RTOs is primarily on the destruction of gaseous pollutants rather than the capture and removal of particulates.

- Supplementary Particulate Control: In certain cases, supplementary particulate control devices may be integrated with RTOs to address particulate matter emissions. These devices, such as bag filters or electrostatic precipitators, can be installed downstream of the RTO to capture and remove particulates. This combination of an RTO with a separate particulate control device can help achieve comprehensive air pollution control for both gaseous pollutants and particulate matter.

- Consideration of Particulate Characteristics: When evaluating the suitability of RTOs for a specific application involving particulate matter emissions, it is crucial to consider the characteristics of the particulates, such as size, composition, and concentration. RTOs may be more effective in controlling certain types of coarse particulates compared to fine or ultrafine particulate matter.

- Alternative Technologies: For industries with significant particulate matter emissions, other air pollution control technologies specifically designed for particulate removal, such as fabric filters (baghouses), electrostatic precipitators, or wet scrubbers, may be more suitable and efficient.

In summary, while regenerative thermal oxidizers are highly effective for the destruction of gaseous pollutants, they are not specifically designed for controlling particulate matter emissions. If particulate matter control is a significant concern, supplementary particulate control devices or alternative technologies should be considered to ensure comprehensive air pollution control.

Can regenerative thermal oxidizers handle corrosive exhaust gases?

Regenerative thermal oxidizers (RTOs) can be designed to handle corrosive exhaust gases effectively. However, the ability of an RTO to handle corrosive gases depends on several factors, including the choice of construction materials, operating conditions, and the specific corrosive nature of the exhaust gases. Here are some key points regarding the handling of corrosive exhaust gases in RTOs:

- Material Selection: The selection of appropriate construction materials is crucial when dealing with corrosive gases. RTOs can be constructed using materials that offer high resistance to corrosion, such as stainless steel, corrosion-resistant alloys (e.g., Hastelloy, Inconel), or coated materials. The choice of materials depends on the specific corrosive compounds present in the exhaust gases and their concentrations.

- Corrosion-Resistant Coatings: In addition to selecting corrosion-resistant materials, applying protective coatings can enhance the resistance of the RTO components to corrosive gases. Coatings such as ceramic coatings, epoxy coatings, or acid-resistant paints can provide an extra layer of protection against corrosion.

- Temperature Control: Maintaining appropriate operating temperatures in the RTO can help mitigate the corrosive effects of the exhaust gases. Higher temperatures can promote the decomposition of corrosive compounds, reducing their corrosive potential. Additionally, operating at higher temperatures can enhance the self-cleaning effect and prevent the accumulation of corrosive deposits on the surfaces.

- Gas Conditioning: Prior to entering the RTO, the exhaust gases can undergo gas conditioning processes to reduce their corrosive nature. This may involve pre-treatment methods such as scrubbing or neutralization to remove or neutralize corrosive compounds and reduce their concentration.

- Monitoring and Maintenance: Regular monitoring of the RTO performance and periodic maintenance are essential to ensure the effective handling of corrosive exhaust gases. Monitoring systems can track variables such as temperature, pressure, and gas composition to detect any deviations that may indicate corrosion-related issues. Proper maintenance, including cleaning and inspection of the components, helps identify and address any corrosion concerns in a timely manner.

It is important to note that the corrosiveness of exhaust gases can vary significantly depending on the specific industrial process and the pollutants involved. Therefore, when designing an RTO for handling corrosive gases, it is advisable to consult with experienced engineers or RTO manufacturers who can provide guidance on the appropriate design considerations and material selection.

By employing suitable materials, coatings, temperature control, gas conditioning, and maintenance practices, RTOs can effectively handle corrosive exhaust gases while ensuring their long-term performance and durability.

What is the lifespan of a regenerative thermal oxidizer?

The lifespan of a regenerative thermal oxidizer (RTO) can vary depending on several factors, including the quality of the equipment, proper maintenance, operating conditions, and technological advancements. Generally, a well-designed and properly maintained RTO can have a lifespan ranging from 15 to 25 years or more.

Here are some factors that can influence the lifespan of an RTO:

- Quality of Construction: RTOs constructed with high-quality materials, such as corrosion-resistant alloys and refractory linings, tend to have a longer lifespan. Robust construction ensures durability and resistance to the harsh operating conditions often encountered in industrial processes.

- Maintenance Practices: Regular and proactive maintenance is crucial to maximize the lifespan of an RTO. This includes periodic inspections, cleaning and replacement of components, such as valves, dampers, and ceramic media beds, and monitoring of operating parameters. Adequate maintenance helps prevent premature equipment failure and ensures optimal performance.

- Operating Conditions: The operating conditions of the RTO, such as temperature, gas composition, and particulate loading, can affect its lifespan. Operating the RTO within its design parameters and avoiding excessive thermal or chemical stresses can contribute to a longer lifespan.

- Technological Advancements: Over time, technological advancements may lead to the introduction of more efficient and durable components or improvements in the overall design of RTOs. Upgrading or retrofitting an older RTO with newer technologies can extend its lifespan and enhance its performance.

- Environmental Factors: Environmental factors, such as exposure to corrosive gases, high humidity, or harsh climates, can impact the lifespan of an RTO. Proper design considerations and protective measures, such as corrosion-resistant coatings or insulation, can mitigate these effects and prolong the equipment’s lifespan.

It is important to note that the lifespan mentioned is a general estimate and can vary depending on the specific circumstances. Regular inspections, maintenance, and adherence to manufacturer’s guidelines are essential to ensure the longevity and reliable operation of an RTO.

محرر بواسطة CX 2023-09-01