基本訊息

型號

Amazing RTO

類型

Incinerator

Low Maintenance

100

Easy Operation

100

Energy Saving

100

High Efficiency

100

商標

Bjamazing

運輸套餐

Overseas

Specification

111

起源

China

HS Code

2221111

產品描述

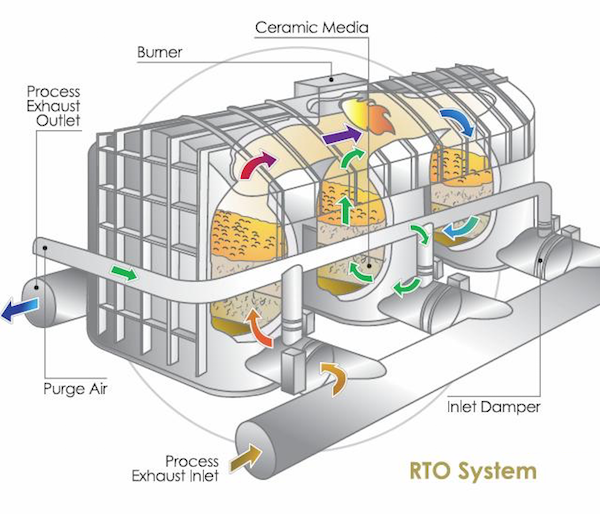

RTO

蓄熱式熱氧化器

Compared with traditional catalytic combustion, direct thermal oxidizer, RTO has the merits of high heating efficiency, low operation cost, and the ability to treat large flux low concentration waste gas. When VOCs concentration is high, secondary heat recycle can be realized, which will greatly reduce the operation cost. Because RTO can preheat the waste gas by levels through ceramic heat accumulator, which could make the waste gas to be completely heated and cracked with no dead corner(treatment efficiency>99%),which reduce the NOX in the Exhausting gas, if the VOC density >1500mg/Nm3, when the waste gas reach cracking area, it has been heated up to cracking temperature by heat accumulator, the burner will be closed under this condition.

RTO can be devided into chamber type and rotary type according to difference operation mode. Rotary type RTO has advantages in system pressure, temperature stability, investment amount, etc

| RTO types | Efficiency | Pressure change (mmAq) | 尺寸 | (max)Treatment volume | |

| Treatment efficiency | Heat recycle efficiency | ||||

| Rotary type RTO | 99 % | 97 % | 0-4 | small (1 time) | 50000Nm3/h |

| Three chamber type RTO | 99 % | 97 % | 0-10 | Large (1.5times) | 100000Nm3/h |

| Two chamber type RTO | 95 % | 95 % | 0-20 | middle (1.2times) | 100000Nm3/h |

Regenerative Thermal Oxidizer, Regenerative Thermal Oxidizer, Regenerative Thermal Oxidizer, Thermal Oxidizer, Thermal Oxidizer, Thermal Oxidizer, oxidizer, oxidizer, oxidizer, incinerator, incinerator, incinerator, waste gas treatment, waste gas treatment, waste gas treatment, VOC treatment, VOC treatment, VOC treatment, RTO, RTO, RTO, Rotary RTO, Rotary RTO, Rotary RTO, Chamber RTO, Chamber RTO, Chamber RTO

Address: 8 floor, E1, Pinwei building, Dishengxi road, Yizhuang, ZheJiang , China

業務類型: 製造商/工廠, 貿易公司

Business Range: Electrical & Electronics, Industrial Equipment & Components, Manufacturing & Processing Machinery, Metallurgy, Mineral & Energy

Management System Certification: ISO 9001, ISO 14001

Main Products: Rto, Color Coating Line, Galvanizing Line, Air Knife, Spares for Processing Line, Coater, Independent Equipments, Sink Roll, Revamping Project, Blower

Company Introduction: ZheJiang Amazing Science & Technology Co., Ltd is a thriving Hi-tech company, located in ZheJiang Economic and Technological Development Area(BDA). Adhering to the concept of Realistic, Innovative, Focused and Efficient, our company mainly serve the waste gas treatment (VOCs) Industry and metallurgical equipment of China and even whole world. We have advanced technology and rich experience in VOCs waste gas treatment project, the reference of which has been successfully applied to the industry of coating, rubber, electronic, printing, etc. We also have years of technology accumulation in the research and manufacturing of flat steel processing line, and possess nearly 100 of application example.

Our company focus on the research, design, manufacturing, installation and commissioning of VOCs organic waste gas treatment system and the revamping and updating project for energy saving and environmental protection of flat steel processing line. We can provide customers the complete solutions for environmental protection, energy saving, product quality improvement and other aspects.

We are also engaged in various spares and independent equipment for color coating line, galvanizing line, pickling line, like roller, coupler, heat exchanger, recuperator, air knife, blower, welder, tension leveler, skin pass, expansion joint, shear, jointer, stitcher, burner, radiant tube, gear motor, reducer, etc.

蓄熱式熱氧化器可以處理不同濃度的污染物嗎?

蓄熱式熱氧化器 (RTO) 旨在有效處理變化的污染物濃度。它們能夠適應污染物濃度的波動,而不會對其性能或效率產生重大不利影響。 RTO 處理可變污染物濃度的能力是使其適合廣泛工業應用的優點之一。

以下是關於 RTO 處理可變污染物濃度的能力需要考慮的一些關鍵點:

- 破壞效率高: RTO 以其高破壞效率而聞名,這是指它們有效破壞或氧化廢氣中污染物的能力。 RTO 內的燃燒室旨在保持足夠高的溫度,以確保污染物完全氧化,無論污染物濃度如何。

- 保留時間: RTO 設計為在燃燒室內有足夠的停留或保留時間。這使得廢氣在高溫區停留足夠的時間,確保即使是不同濃度的污染物也能得到充分的處理和氧化。

- 熱回收: RTO 中的熱回收系統通常使用陶瓷介質床或熱交換器,在處理可變污染物濃度方面發揮至關重要的作用。即使在污染物濃度較低的時期,熱回收系統也有助於維持所需的溫度並提供熱能來維持燃燒過程。

- 動態運作: RTO 設計為動態運行,這意味著它們可以調整其運行參數以適應污染物濃度的變化。它們可以調節廢氣和進入的未處理氣體的流量、溫度設定點以及床的切換頻率等變量,以優化不同污染物負荷下的性能。

- 監控與控制: RTO 配備了先進的監測和控制系統,可連續監測污染物濃度、溫度和其他相關參數。這些系統能夠即時調整和優化 RTO 運行,以確保有效處理可變污染物濃度。

雖然 RTO 可以處理可變的污染物濃度,但值得注意的是,極端或高度波動的污染物濃度可能需要額外考慮。在某些情況下,可以採用廢氣稀釋或調節等預處理方法來確保 RTO 的最佳性能。

總體而言,RTO 是一種多功能且可靠的系統,可有效處理可變的污染物濃度,從而提供高效且一致的工業排放處理。

再生熱氧化器與生物過濾器的性能相比如何?

蓄熱式熱氧化器(RTO)和生物過濾器都是廣泛使用的空氣污染物處理技術,但它們的工作原理和性能特徵有所不同。以下是 RTO 和生物過濾器的性能比較:

| 性能方面 | 蓄熱式熱氧化器 (RTO) | 生物過濾器 |

|---|---|---|

| 排放去除效率 | RTO 在去除揮發性有機化合物 (VOC) 和有害空氣污染物 (HAP) 方面非常有效率。他們對這些污染物的破壞效率可達 95% 以上。 | 生物過濾器還有可能對某些揮發性有機化合物和有氣味的化合物實現高去除效率。然而,它們的性能可能會根據生物過濾器中的特定污染物和微生物活性而變化。 |

| 適用性 | RTO 用途廣泛,可以處理多種污染物,包括 VOC、HAP 和有味化合物。它們非常適合高流量和高污染物濃度。 | 生物過濾器在處理有氣味的化合物和某些揮發性有機化合物方面特別有效。它們通常用於廢水處理設施、堆肥作業和農業設施等應用。 |

| 能源消耗 | RTO 需要大量能量才能達到並維持氧化的高工作溫度。它們依靠燃料燃燒或外部熱源來獲取所需的熱能。 | 生物過濾器被認為是低能耗系統,因為它們依靠微生物的自然生物活性來分解污染物。它們通常不需要外部加熱或燃料消耗。 |

| 維護 | RTO 通常需要定期維護和監控以確保正常運作。這包括檢查、熱交換介質的清潔以及組件的潛在維修或更換。 | 生物過濾器需要定期維護以優化其性能。這可能涉及監測和調整濕度水平、控制溫度以及偶爾更換過濾介質或添加微生物接種劑。 |

| 資本和營運成本 | 與生物過濾器相比,RTO 由於其複雜的設計、專用材料和能源密集型操作,通常具有更高的資本成本。營運成本包括燃料消耗或暖氣用電。 | 與 RTO 相比,生物過濾器的資本成本通常較低。它們設計更簡單,並且不需要燃料消耗。然而,營運成本可能包括定期更換過濾介質和潛在的氣味控制措施。 |

值得注意的是,選擇合適的技術取決於多種因素,例如待處理的特定污染物、製程條件、監管要求和特定場地的考慮因素。諮詢環境工程師或空氣污染控制專家可以幫助確定最適合特定應用的技術。

綜上所述,RTO 和生物過濾器具有不同的性能特徵,RTO 具有去除效率高、通用性強、適合高流量和高濃度應用的優點,而生物過濾器對有氣味的化合物有效,能耗低,且資本通常較低成本。

How do regenerative thermal oxidizers handle start-up and shutdown procedures?

Regenerative thermal oxidizers (RTOs) have specific procedures for start-up and shutdown to ensure safe and efficient operation. These procedures are designed to optimize the performance of the RTO and minimize any potential risks. Here is an overview of how RTOs handle start-up and shutdown:

- Start-up Procedure: During start-up, the RTO goes through a series of steps to reach its operating temperature. The start-up procedure typically involves the following stages:

- Purge Stage: The RTO is purged with clean air or an inert gas to remove any potential flammable or explosive gases that may have accumulated during the shutdown period.

- Preheat Stage: The RTO’s heat exchangers are preheated using a burner or an auxiliary heat source. This gradually increases the temperature of the heat exchange media (typically ceramic or metallic beds) and the combustion chamber.

- Heat Soak Stage: Once the heat exchangers reach a certain temperature, the RTO enters the heat soak stage. In this stage, the heat exchangers are fully heated, and the RTO operates in a self-sustaining mode, with the combustion chamber temperature being maintained primarily by the heat released from the oxidation of pollutants in the exhaust gas.

- Normal Operation: After the heat soak stage, the RTO is considered to be in normal operation mode, where it maintains the desired operating temperature and treats the exhaust gas containing pollutants.

- Shutdown Procedure: The shutdown procedure of an RTO is aimed at safely and efficiently stopping the operation of the system. The procedure typically involves the following steps:

- Cool Down: The RTO is gradually cooled down by reducing the flow of the exhaust gas and the supply of combustion air. This helps to prevent thermal stress on the equipment and minimize the risk of fires or other safety hazards.

- 熱回收: During the cool-down phase, the RTO may employ heat recovery techniques to capture and utilize the residual heat for other purposes, such as preheating incoming process air or water.

- Purge: Once the RTO has cooled down sufficiently, a purge cycle is initiated to remove any residual gases or contaminants from the system. This helps to ensure a clean and safe environment for maintenance activities or subsequent start-ups.

- Complete Shutdown: After the purge cycle, the RTO is considered to be in a fully shut-down state, and it can remain in this state until the next start-up is initiated.

It is important to note that the specific start-up and shutdown procedures for an RTO may vary depending on the design and manufacturer. Manufacturers typically provide detailed guidelines and instructions for operating their specific RTO models, and it is crucial to follow these guidelines to ensure safe and efficient operation.

editor by CX 2023-10-13