Basic Info.

Model NO.

Amazing RTO

Tip

Incinerator

Întreținere redusă

100

Easy Operation

100

Energy Saving

100

High Efficiency

100

Trademark

Bjamazing

Transport Package

Overseas

Specification

111

Origin

China

HS Code

2221111

Product Description

RTO

Oxidant termic regenerativ

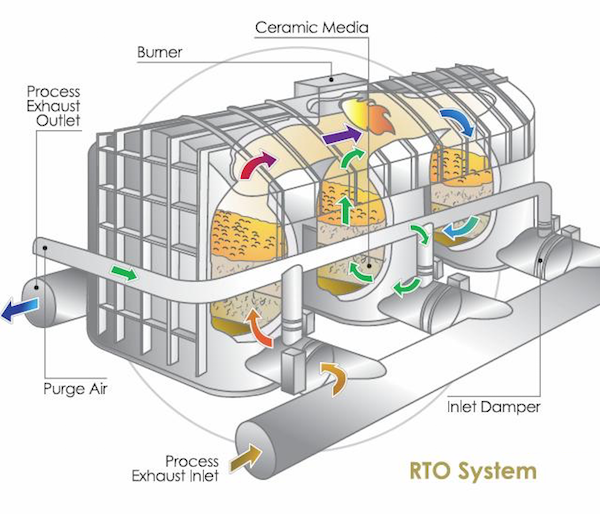

Compared with traditional catalytic combustion, direct thermal oxidizer, RTO has the merits of high heating efficiency, low operation cost, and the ability to treat large flux low concentration waste gas. When VOCs concentration is high, secondary heat recycle can be realized, which will greatly reduce the operation cost. Because RTO can preheat the waste gas by levels through ceramic heat accumulator, which could make the waste gas to be completely heated and cracked with no dead corner(treatment efficiency>99%),which reduce the NOX in the Exhausting gas, if the VOC density >1500mg/Nm3, when the waste gas reach cracking area, it has been heated up to cracking temperature by heat accumulator, the burner will be closed under this condition.

RTO can be devided into chamber type and rotary type according to difference operation mode. Rotary type RTO has advantages in system pressure, temperature stability, investment amount, etc

| RTO types | Efficiency | Pressure change (mmAq) | Size | (max)Treatment volume | |

| Treatment efficiency | Heat recycle efficiency | ||||

| Rotary type RTO | 99 % | 97 % | 0-4 | small (1 time) | 50000Nm3/h |

| Three chamber type RTO | 99 % | 97 % | 0-10 | Large (1.5times) | 100000Nm3/h |

| Two chamber type RTO | 95 % | 95 % | 0-20 | middle (1.2times) | 100000Nm3/h |

Regenerative Thermal Oxidizer, Regenerative Thermal Oxidizer, Regenerative Thermal Oxidizer, Thermal Oxidizer, Thermal Oxidizer, Thermal Oxidizer, oxidizer, oxidizer, oxidizer, incinerator, incinerator, incinerator, waste gas treatment, waste gas treatment, waste gas treatment, VOC treatment, VOC treatment, VOC treatment, RTO, RTO, RTO, Rotary RTO, Rotary RTO, Rotary RTO, Chamber RTO, Chamber RTO, Chamber RTO

Address: 8 floor, E1, Pinwei building, Dishengxi road, Yizhuang, ZheJiang , China

Business Type: Manufacturer/Factory, Trading Company

Business Range: Electrical & Electronics, Industrial Equipment & Components, Manufacturing & Processing Machinery, Metallurgy, Mineral & Energy

Management System Certification: ISO 9001, ISO 14001

Main Products: Rto, Color Coating Line, Galvanizing Line, Air Knife, Spares for Processing Line, Coater, Independent Equipments, Sink Roll, Revamping Project, Blower

Company Introduction: ZheJiang Amazing Science & Technology Co., Ltd is a thriving Hi-tech company, located in ZheJiang Economic and Technological Development Area(BDA). Adhering to the concept of Realistic, Innovative, Focused and Efficient, our company mainly serve the waste gas treatment (VOCs) Industry and metallurgical equipment of China and even whole world. We have advanced technology and rich experience in VOCs waste gas treatment project, the reference of which has been successfully applied to the industry of coating, rubber, electronic, printing, etc. We also have years of technology accumulation in the research and manufacturing of flat steel processing line, and possess nearly 100 of application example.

Our company focus on the research, design, manufacturing, installation and commissioning of VOCs organic waste gas treatment system and the revamping and updating project for energy saving and environmental protection of flat steel processing line. We can provide customers the complete solutions for environmental protection, energy saving, product quality improvement and other aspects.

We are also engaged in various spares and independent equipment for color coating line, galvanizing line, pickling line, like roller, coupler, heat exchanger, recuperator, air knife, blower, welder, tension leveler, skin pass, expansion joint, shear, jointer, stitcher, burner, radiant tube, gear motor, reducer, etc.

Can regenerative thermal oxidizers handle variable pollutant concentrations?

Regenerative thermal oxidizers (RTOs) are designed to handle variable pollutant concentrations effectively. They are capable of accommodating fluctuations in pollutant concentrations without significant adverse effects on their performance or efficiency. The ability of RTOs to handle variable pollutant concentrations is one of the advantages that make them suitable for a wide range of industrial applications.

Here are some key points to consider regarding the capability of RTOs to handle variable pollutant concentrations:

- High Destruction Efficiency: RTOs are known for their high destruction efficiency, which refers to their ability to effectively destroy or oxidize the pollutants present in the exhaust gases. The combustion chamber within the RTO is designed to maintain a sufficiently high temperature to ensure complete oxidation of the pollutants, regardless of their concentration.

- Retention Time: RTOs are designed with a sufficient residence or retention time within the combustion chamber. This allows the exhaust gases to spend enough time in the high-temperature zone, ensuring that even pollutants with varying concentrations are adequately treated and oxidized.

- Heat Recovery: The heat recovery system in an RTO, typically using ceramic media beds or heat exchangers, plays a crucial role in handling variable pollutant concentrations. The heat recovery system helps maintain the required temperature and provides thermal energy to sustain the combustion process, even during periods of low pollutant concentrations.

- Dynamic Operation: RTOs are designed to operate dynamically, meaning they can adjust their operating parameters to accommodate changes in pollutant concentrations. They can modulate variables such as the flow rates of the exhaust gases and incoming untreated gases, the temperature setpoints, and the switching frequency of the beds to optimize performance under varying pollutant loads.

- Monitoring and Controls: RTOs are equipped with advanced monitoring and control systems that continuously monitor pollutant concentrations, temperature, and other relevant parameters. These systems enable real-time adjustments and optimization of the RTO operation to ensure effective treatment of variable pollutant concentrations.

While RTOs can handle variable pollutant concentrations, it’s important to note that extreme or highly fluctuating pollutant concentrations may require additional considerations. In some cases, pre-treatment methods such as dilution or conditioning of the exhaust gases may be employed to ensure optimal performance of the RTO.

Overall, RTOs are versatile and reliable systems that can effectively handle variable pollutant concentrations, providing efficient and consistent treatment of industrial emissions.

How do regenerative thermal oxidizers compare to biofilters in terms of performance?

Regenerative thermal oxidizers (RTOs) and biofilters are both widely used technologies for the treatment of air pollutants, but they differ in their operating principles and performance characteristics. Here’s a comparison of RTOs and biofilters in terms of their performance:

| Performance Aspect | Regenerative Thermal Oxidizers (RTOs) | Biofilters |

|---|---|---|

| Emission Removal Efficiency | RTOs are highly efficient in removing volatile organic compounds (VOCs) and hazardous air pollutants (HAPs). They can achieve destruction efficiencies above 95% for these pollutants. | Biofilters also have the potential to achieve high removal efficiencies for certain VOCs and odorous compounds. However, their performance can vary depending on the specific contaminants and the microbial activity in the biofilter. |

| Applicability | RTOs are versatile and can handle a wide range of pollutants, including VOCs, HAPs, and odorous compounds. They are well-suited for high flow rates and high pollutant concentrations. | Biofilters are particularly effective in treating odorous compounds and certain VOCs. They are commonly used in applications such as wastewater treatment facilities, composting operations, and agricultural facilities. |

| Energy Consumption | RTOs require a significant amount of energy to reach and maintain high operating temperatures for oxidation. They rely on fuel combustion or external heat sources for the thermal energy needed. | Biofilters are considered low energy consumption systems as they rely on the natural biological activity of microorganisms to break down pollutants. They generally do not require external heating or fuel consumption. |

| Maintenance | RTOs typically require regular maintenance and monitoring to ensure proper operation. This includes inspections, cleaning of heat exchange media, and potential repairs or replacements of components. | Biofilters require periodic maintenance to optimize their performance. This may involve monitoring and adjusting moisture levels, controlling temperature, and occasionally replacing the filter media or adding microbial inoculants. |

| Capital and Operating Costs | RTOs generally have higher capital costs compared to biofilters due to their complex design, specialized materials, and energy-intensive operation. Operating costs include fuel consumption or electricity for heating. | Biofilters generally have lower capital costs compared to RTOs. They are simpler in design and do not require fuel consumption. However, operating costs may include periodic replacement of filter media and potential odor control measures. |

It is important to note that the selection of the appropriate technology depends on various factors such as the specific pollutants to be treated, process conditions, regulatory requirements, and site-specific considerations. Consulting with environmental engineers or air pollution control experts can help determine the most suitable technology for a particular application.

In summary, RTOs and biofilters offer different performance characteristics, with RTOs excelling in high removal efficiencies, versatility, and suitability for high-flow and high-concentration applications, while biofilters are effective for odorous compounds, have low energy consumption, and generally lower capital costs.

How do regenerative thermal oxidizers handle start-up and shutdown procedures?

Regenerative thermal oxidizers (RTOs) have specific procedures for start-up and shutdown to ensure safe and efficient operation. These procedures are designed to optimize the performance of the RTO and minimize any potential risks. Here is an overview of how RTOs handle start-up and shutdown:

- Start-up Procedure: During start-up, the RTO goes through a series of steps to reach its operating temperature. The start-up procedure typically involves the following stages:

- Purge Stage: The RTO is purged with clean air or an inert gas to remove any potential flammable or explosive gases that may have accumulated during the shutdown period.

- Preheat Stage: The RTO’s heat exchangers are preheated using a burner or an auxiliary heat source. This gradually increases the temperature of the heat exchange media (typically ceramic or metallic beds) and the combustion chamber.

- Heat Soak Stage: Once the heat exchangers reach a certain temperature, the RTO enters the heat soak stage. In this stage, the heat exchangers are fully heated, and the RTO operates in a self-sustaining mode, with the combustion chamber temperature being maintained primarily by the heat released from the oxidation of pollutants in the exhaust gas.

- Normal Operation: After the heat soak stage, the RTO is considered to be in normal operation mode, where it maintains the desired operating temperature and treats the exhaust gas containing pollutants.

- Shutdown Procedure: The shutdown procedure of an RTO is aimed at safely and efficiently stopping the operation of the system. The procedure typically involves the following steps:

- Cool Down: The RTO is gradually cooled down by reducing the flow of the exhaust gas and the supply of combustion air. This helps to prevent thermal stress on the equipment and minimize the risk of fires or other safety hazards.

- Heat Recovery: During the cool-down phase, the RTO may employ heat recovery techniques to capture and utilize the residual heat for other purposes, such as preheating incoming process air or water.

- Purge: Once the RTO has cooled down sufficiently, a purge cycle is initiated to remove any residual gases or contaminants from the system. This helps to ensure a clean and safe environment for maintenance activities or subsequent start-ups.

- Complete Shutdown: After the purge cycle, the RTO is considered to be in a fully shut-down state, and it can remain in this state until the next start-up is initiated.

It is important to note that the specific start-up and shutdown procedures for an RTO may vary depending on the design and manufacturer. Manufacturers typically provide detailed guidelines and instructions for operating their specific RTO models, and it is crucial to follow these guidelines to ensure safe and efficient operation.

editor by CX 2023-10-13