معلومات اساسية.

نموذج رقم.

LC-JYRT-1 متر/ساعة؛

خصائص الأداء

حجم الهواء للمعالجة من 2nm3/h

التركيز ≥ 1000 ملغم / م3

أسئلة وأجوبة العملاء

إذا كان لديك أي أسئلة، يرجى ترك تعليقاتك القيمة

العنوان: 316، رقم 331، طريق تشنغنان، شارع لانتشنغ، مدينة هانغتشو، مقاطعة تشجيانغ

نوع العمل: مصنع/شركة مصنعة

نطاق العمل: المعدات والمكونات الصناعية

المنتجات الرئيسية: توليد الطاقة من حرق النفايات، حرق النفايات، توليد الطاقة المتجددة، محطة توليد الطاقة من حرق النفايات، محرقة النفايات، الطاقة

مقدمة عن الشركة: شركة HangZhou Lancheng Environmental Protection Technology المحدودة، التي تقع في مدينة HangZhou، مدينة HangZhou، مقاطعة ZheJiang، هي شركة ذات تكنولوجيا عالية تجمع بين البحث العلمي والتصميم والإنتاج والمبيعات. تسعى الشركة إلى الابتكار من خلال البحث العلمي، والبقاء من خلال الجودة والتطوير من خلال السمعة. بفضل مستواها المهني وتقنيتها الناضجة في مجال حماية البيئة، فإنها ترتفع بسرعة. رضا العملاء عن المنتجات هو هدفنا الدائم.

برأس مال مسجل يبلغ 20 مليون يوان، تمتلك الشركة أكثر من 2000 قاعدة إنتاج حديثة في منطقة هانغتشو هونغ كونغ الصناعية، مدينة هانغتشو، مدينة هانغتشو، مقاطعة تشجيانغ. وقد صمم مصممو المعالجة البيئية من الدرجة الأولى في الشركة مخططات معالجة مستهدفة من جوانب عقلانية النظام والابتكار التكنولوجي واقتصاد المدخلات والمخرجات لمختلف ظروف العمل المعقدة، وذلك لجعل مؤشرات الانبعاثات تلبي معايير الانبعاثات الوطنية.

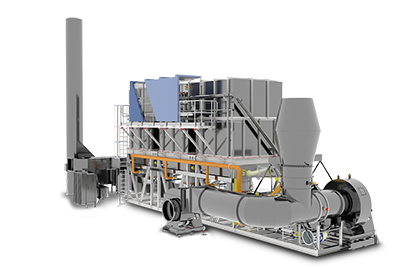

المنتجات الرئيسية للشركة هي: 1. غاز النفايات العضوية؛ الكربون المنشط، RTO، RCO، عداء الزيوليت، صندوق الفلتر الجاف، إلخ. 2. الغبار؛ المرسب الكهروستاتيكي، مرشح كيس النبض وغيرها من المعدات. 3. المعدات الصيدلانية؛ معدات التجفيف، معدات الخلط، معدات التحبيب، معدات التكسير. 4. الأسلاك المجلفنة بالغمس الساخن. 5. معدات معالجة مياه الصرف الصناعي، إلخ.

تم استخدام معداتنا بنجاح في الصناعة الكيميائية، والخبز، والطلاء، والطلاء الكهربائي، وحرق النفايات، والطباعة، والمطاعم، والبلديات وغيرها من الصناعات. في الوقت الحاضر، يمكن للشركة صياغة مخطط معالجة مثالي وفقًا للوضع الحالي لتصريف مياه الصرف الصحي في المؤسسة، واستخدام التكنولوجيا الحاصلة على براءة اختراع الحالية لتطوير المنتجات الأكثر ملاءمة. سنقدم لك أفضل الحلول ذات الجودة مع أحدث التقنيات وأكثر المواقف صدقًا.

تتخذ الشركة دائمًا "النحت بعناية وإنشاء منتجات عالية الجودة" كغرض للمؤسسة، وتتخذ دائمًا "النمو إلى أقوى مؤسسة لحماية البيئة في منطقة شيهو (بحيرة الغرب)" كهدف للمؤسسة. في السنوات الأخيرة، مع الاهتمام المتزايد من الدولة بحماية البيئة، أصبحت "إدارة الغلاف الجوي وتجميل البيئة وإفادة البشرية" مهمتنا طويلة الأمد. استجابة لدعوة سياسة "الحفاظ على الطاقة والحد من الانبعاثات" الوطنية، قدمت شركة حماية البيئة في المدينة الزرقاء مساهمات مناسبة لإحياء حماية البيئة في الصين وبناء مجتمع متناغم، وتواصل السعي لخلق سماء أكثر زرقة وبيئة أفضل لنا!

Are regenerative thermal oxidizers suitable for small-scale applications?

Regenerative thermal oxidizers (RTOs) are primarily designed for medium to large-scale industrial applications due to their specific characteristics and operational requirements. However, their suitability for small-scale applications depends on various factors:

- Process Exhaust Volume: The exhaust volume generated by the small-scale application plays a crucial role in determining the feasibility of using an RTO. RTOs are typically designed to handle high exhaust volumes, and if the exhaust volume from the small-scale application is too low, it may not be cost-effective or efficient to use an RTO.

- Capital and Operating Costs: RTOs can be expensive to purchase, install, and operate. The capital investment required for a small-scale application may not be justifiable when considering the relatively lower exhaust volumes and pollutant concentrations. Additionally, the operating costs, including energy consumption and maintenance, may outweigh the benefits for small-scale operations.

- توفر المساحة: RTOs require a significant amount of physical space for installation. Small-scale applications may have space limitations, making it challenging to accommodate the size and layout requirements of an RTO system.

- Regulatory Requirements: Small-scale applications may be subject to different regulatory requirements compared to larger industrial operations. The specific emission limits and air quality standards applicable to the small-scale application should be considered to ensure compliance. Alternative emission control technologies that are more suitable for small-scale applications, such as catalytic oxidizers or biofilters, may be available.

- Process Characteristics: The nature of the small-scale application’s exhaust stream, including the type and concentration of pollutants, can influence the choice of emission control technology. RTOs are most effective for applications with high concentrations of volatile organic compounds (VOCs) and hazardous air pollutants (HAPs). If the pollutant profile of the small-scale application is different, alternative technologies may be more appropriate.

While RTOs are generally more suitable for medium to large-scale applications, it’s important to assess the specific requirements, constraints, and cost-benefit analysis for each individual small-scale application before considering the use of an RTO. Alternative emission control technologies that are better suited for small-scale operations should also be evaluated.

Can regenerative thermal oxidizers handle high-temperature exhaust streams?

Regenerative thermal oxidizers (RTOs) are designed to handle high-temperature exhaust streams efficiently. They are capable of accommodating exhaust gases with elevated temperatures and effectively treating them for pollutant removal. Here are some key points regarding the handling of high-temperature exhaust streams in RTOs:

- Thermal Stability: RTOs are constructed using materials that can withstand high temperatures, typically ranging from 800 to 1,500 degrees Celsius (1,472 to 2,732 degrees Fahrenheit). The combustion chamber, heat exchangers, and other components are designed to maintain their structural integrity and thermal stability under these conditions.

- استعادة الحرارة: One of the primary advantages of RTOs is their ability to recover and reuse heat from the high-temperature exhaust streams. The heat exchangers within the RTO capture the thermal energy from the outgoing exhaust gases and transfer it to the incoming process air or gas stream. This heat recovery process improves the overall energy efficiency of the system and reduces the need for additional fuel consumption.

- Effective Combustion: RTOs are equipped with combustion chambers where the high-temperature exhaust gases are directed. In the combustion chamber, the pollutants in the exhaust stream are oxidized at high temperatures, typically above the autoignition temperature of the pollutants. This ensures effective destruction of the pollutants, even in high-temperature environments.

- Heat Exchange: RTOs utilize a regenerative heat exchange system, which allows for the efficient transfer of heat between the incoming and outgoing gas streams. The heat exchange media within the RTO alternately absorbs and releases heat, enabling the preheating of the incoming gases and cooling of the outgoing gases. This heat exchange process helps maintain the desired operating temperatures within the RTO while maximizing energy recovery.

- System Design Considerations: When handling high-temperature exhaust streams, proper system design is crucial. Factors such as the choice of materials, insulation, and thermal expansion considerations are taken into account to ensure safe and efficient operation at elevated temperatures. Additionally, temperature monitoring and control systems are implemented to maintain optimal operating conditions.

It is important to note that the specific temperature limits and capabilities of an RTO may vary depending on the design, materials used, and the specific requirements of the application. Consulting with experienced engineers or RTO manufacturers can provide valuable insights into the suitability of an RTO for handling a particular high-temperature exhaust stream.

Overall, RTOs are well-suited for handling high-temperature exhaust streams, offering effective pollutant destruction, heat recovery, and energy efficiency in industrial applications.

What industries commonly use regenerative thermal oxidizers?

Regenerative thermal oxidizers (RTOs) are widely used in various industries that generate volatile organic compounds (VOCs), hazardous air pollutants (HAPs), and other harmful emissions. Some of the industries that commonly use RTOs for air pollution control include:

- Chemical Manufacturing: RTOs are extensively employed in chemical manufacturing processes that produce solvents, paints, coatings, adhesives, and other chemical products. These industries often generate significant amounts of VOCs that require effective control and abatement.

- Printing and Packaging: The printing and packaging industry utilizes RTOs to control the emissions of VOCs and HAPs from ink drying, coating, and solvent-based processes. RTOs ensure compliance with environmental regulations while maintaining high-quality printing standards.

- Pharmaceuticals: Pharmaceutical manufacturing processes often involve the use of solvents and organic compounds, leading to the generation of VOCs. RTOs provide an effective solution for capturing and destroying these emissions, ensuring a safe and environmentally friendly production environment.

- Paint and Coatings: RTOs are commonly employed in paint and coatings manufacturing facilities to control VOC emissions during the curing and drying processes. By effectively destroying VOCs, RTOs help reduce the environmental impact of these industries while maintaining product quality.

- Furniture and Woodworking: The furniture and woodworking industry utilizes RTOs to control emissions from processes such as painting, staining, and varnishing. RTOs help remove VOCs and HAPs generated during these operations, promoting a healthier working environment and reducing the impact on surrounding communities.

- Food Processing: Certain food processing operations generate VOCs and odorous compounds. RTOs are used in these industries to capture and treat emissions from cooking, baking, frying, and other food-related processes. RTOs ensure compliance with air quality standards while minimizing the impact on food quality and safety.

- Chemical Storage and Handling: Facilities involved in the storage and handling of chemicals, such as bulk liquid terminals and chemical distribution centers, may utilize RTOs to control emissions from venting and vapor recovery systems. RTOs help mitigate the release of VOCs and HAPs during various storage and transfer operations.

These are just a few examples, and RTOs can be found in many other industries that generate VOCs and HAPs. RTOs provide a versatile and effective solution for air pollution control, ensuring compliance with environmental regulations and promoting sustainable industrial practices.

محرر بواسطة CX 2023-09-01