Coating industry governance scheme

At present EP rotary RTO has been widely used in coating process production of release film, protective film, reflective materials, advertising supplies, adhesive tape, polarizing film, solar backplane film, aluminum-plastic film, lithium battery diaphragm and other enterprises VOCs governance.

- Exhaust characteristics: large air volume, high concentration

- Exhaust gas source: coating oven organized exhaust gas; No organized waste gas of coating head and glue room

- Waste gas components: ethyl acetate, toluene, isopropanol, butanone, n-hexane

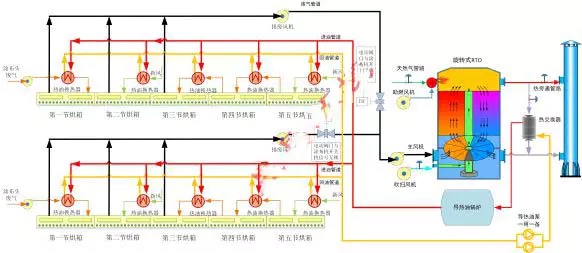

- Process plan: reducing wind and thickening + rotary RTO+ waste heat recovery

- Waste heat recovery: steam recovery, hot air recovery, heat conduction oil recovery

- Exhaust gas concentration: 1500mg/m³ ~ 10000mg/m³

- Emission limit: NMHC≤50mg/m³

If you want to successfully embark on the road to green development as an enterprise to achieve economic development and environmental protection, do not hesitate to contact us to get more about our regenerative thermal oxidizers.