基本訊息

型號

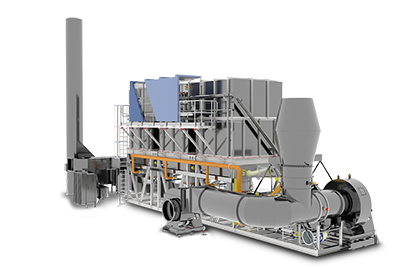

RTO

類型

環境監測儀器

主要功能

廢氣去除

應用

化工

品牌

雷德桑特

清潔效率

99.8%

狀態

新的

商標

雷德桑特

運輸套餐

薄膜包裹

起源

中國 浙江

產品描述

杭州瑞德森機械有限公司;,;有限公司;專業開發製造創新粉末冷卻造粒機械及相關工業廢氣處理設備。具有近20年的生產歷史;我們在中國20多個省份擁有良好的市場;部分產品出口沙烏地阿拉伯、新加坡、墨西哥、巴西,;西班牙,;美國,;俄羅斯和韓國; ETC。

規格:;

* 比現有設施更緊湊

* 營運成本低

* 設施使用壽命長

* 壓力無變化

目的:;

燃燒揮發性有機化合物(VOC)的節能係統;利用熱量產生廢氣;採用陶瓷蓄熱材料(催化劑)收集99.;8%以上的廢氣餘熱;表面積大,壓力損失低;

應用:;

1.;塗裝乾燥工藝

2.;金屬印刷工藝

3.;纖維乾燥過程

4.;膠帶工藝

5.;廢棄物處理工藝

6.;半導體製造工藝

7.;抽煙,;糖果和烘焙過程

8.;石化過程;

9.;醫藥和食品製造過程;

10.;其他VOC產生過程

優點:;

* 比現有設施更緊湊

* 壓力無變化

* 熱回收率高(95%以上);

* 完善的VOC處理(99.;8%以上);

* 設施使用壽命長

* 營運成本低

* 可製作圓形或四邊形

一般描述與特點:;

1.;工作原理

透過旋轉旋轉閥連續改變流量的操作方法

2.;過程壓力變化

由於旋轉閥的旋轉,風向會發生順序變化,因此壓力不會變化

3.;投資成本

約 70% 的床型

4.;安裝空間

它是單一容器,因此結構緊湊,需要的安裝空間較小。

5.;維護

由於旋轉閥是唯一的 1 個移動部件,因此易於維護。

旋轉閥由於旋轉速度低,密封件很少磨損;

6.;穩定

在此過程中沒有風險,因為即使旋轉閥出現故障,它也始終打開。

7.;處理效率

即使長時間運行,密封件也很少磨損,處理效率得以維持;

地址:浙江省杭州市經濟開發區振新中路3號

業務類型: 製造商/工廠, 貿易公司

業務範圍:化工、電氣電子、製造加工機械、安全防護

管理系統認證:ISO 9001

主要產品:造粒機、刨片機、造粒機、造粒機、化學造粒機、Vocs

公司簡介:杭州瑞德森機械有限公司,前身為杭州新特塑膠機械廠,是一家專業生產創新塑膠回收機械的企業。憑藉近20年的經驗,我們在國內20個省市自治區擁有良好的市場,部分產品出口到印尼、俄羅斯、越南等。管材撕碎回收生產線、連續退火鍍錫機、QX型PET、PE及皮殼清洗生產線、SDP雙軌塑膠回收破碎機、SJ熱切造粒機組、PVC管(五葉)生產線、PVC異型材產品門窗生產線、水中顆粒生產線以及塑膠和回收粉碎機。我們獲得了5項技術專利。

本公司注重技術改造,引進國內外先進技術,不斷開發新產品。我們的宗旨是挑戰高品質,提供最好的產品。我們正在努力實現我們的口號。讓客戶滿意是我們永恆的追求。

我們正在尋找海外客戶或代理商。如果您對我們的提案感興趣,請讓我們知道我們的哪種產品最有可能吸引您或您的客戶。如果您能給我們一些關於我們產品的市場前景的想法,我們將不勝感激。我們希望盡快收到您的有利訊息!我們的目標是希望現在或不久的將來能與您建立良好的關係。如果您有任何問題或要求,請隨時與我們聯繫。

我們也真誠歡迎您來本公司洽談業務、洽談業務。為進一步拓展市場與客戶,本公司以全新的經營理念-品質、榮譽、服務,以全新的品牌姿態迎接國內外客戶。我們正在尋找 ISO 90001 管理品質系統來滿足客戶的要求!

Can regenerative thermal oxidizers be used for treating industrial wastewater?

No, regenerative thermal oxidizers (RTOs) are not typically used for treating industrial wastewater. RTOs are specifically designed for air pollution control and the treatment of gaseous pollutants, such as volatile organic compounds (VOCs) and hazardous air pollutants (HAPs).

Here are some key points to consider regarding the use of RTOs for treating industrial wastewater:

- Operating Principle: RTOs rely on the combustion of pollutants in the gas phase. They utilize high temperatures to thermally oxidize gaseous pollutants, converting them into carbon dioxide and water vapor. However, wastewater treatment involves the removal or transformation of contaminants dissolved or suspended in water, which requires different treatment mechanisms.

- Wastewater Treatment Technologies: Wastewater treatment typically involves processes such as physical separation, chemical treatment, biological treatment, and other specialized techniques depending on the nature of the contaminants. Common wastewater treatment technologies include activated sludge systems, sedimentation tanks, chemical precipitation, filtration, and various other methods tailored to specific wastewater characteristics.

- Environmental Regulations: Industrial wastewater treatment is subject to stringent environmental regulations and discharge standards that govern the quality of effluent released into water bodies. Compliance with these regulations requires the implementation of appropriate wastewater treatment technologies specifically designed for the removal or reduction of contaminants in water, rather than air pollution control technologies like RTOs.

- Integration with Wastewater Treatment Systems: While RTOs are not used for wastewater treatment, they may be integrated into overall industrial process systems where wastewater treatment is also required. In such cases, separate wastewater treatment technologies are employed to treat the wastewater, and RTOs are used to address air emissions resulting from the wastewater treatment process or other industrial operations.

In summary, regenerative thermal oxidizers are not suitable for treating industrial wastewater. They are designed for air pollution control and the destruction of gaseous pollutants. For effective wastewater treatment, industries should employ appropriate wastewater treatment technologies specifically designed for the removal or transformation of contaminants in water.

Can regenerative thermal oxidizers be remotely controlled and monitored?

Yes, regenerative thermal oxidizers (RTOs) can be remotely controlled and monitored using advanced automation and control systems. Remote control and monitoring capabilities offer several benefits in terms of operational efficiency, maintenance, and troubleshooting. Here are some key points regarding the remote control and monitoring of RTOs:

- Automation Systems: RTOs can be integrated with automation systems that enable remote control and monitoring. These systems utilize programmable logic controllers (PLCs), distributed control systems (DCS), or other similar technologies to manage and optimize the operation of the RTO.

- Remote Control: With remote control capabilities, operators can adjust and modify the operating parameters of the RTO from a central control room or even remotely through secure network connections. This allows for convenient and efficient control of the RTO, making it easier to optimize performance, adjust settings, and respond to changing process conditions.

- Remote Monitoring: Remote monitoring systems enable real-time monitoring of various parameters and performance indicators of the RTO. These systems can provide insights into the operational status, temperature profiles, gas flow rates, pressure differentials, and other critical variables. Operators can access this information remotely, allowing them to assess the system’s performance, identify potential issues, and make informed decisions.

- Alarms and Notifications: Remote monitoring systems can be programmed to generate alarms and notifications based on predefined conditions or thresholds. This allows operators to receive immediate alerts in case of deviations from normal operating conditions or the occurrence of any critical events. Prompt notifications facilitate timely response and troubleshooting, minimizing downtime and potential risks.

- Data Logging and Analysis: Remote control and monitoring systems often include data logging capabilities, which capture historical data regarding the RTO’s operation and performance. This data can be analyzed to identify trends, evaluate efficiency, and optimize the system’s operation over time. It also helps in compliance reporting and maintenance planning.

- Integration with SCADA Systems: RTOs can be integrated with supervisory control and data acquisition (SCADA) systems, which provide a centralized platform for monitoring and controlling multiple processes and equipment within a facility. Integration with SCADA systems allows for a comprehensive overview of the entire operation and facilitates coordinated control and monitoring of various systems.

It is important to ensure that the remote control and monitoring systems are implemented with appropriate cybersecurity measures to protect against unauthorized access or cyber threats. Manufacturers of RTOs often provide guidance and recommendations for implementing secure remote access to their systems.

Overall, the remote control and monitoring capabilities of RTOs enhance operational efficiency, enable proactive maintenance, and facilitate faster response times, contributing to the effective and optimized operation of the air pollution control system.

What are the maintenance requirements for a regenerative thermal oxidizer?

Maintaining a regenerative thermal oxidizer (RTO) is essential to ensure its optimal performance, longevity, and compliance with environmental regulations. Here are some key maintenance requirements for an RTO:

- Regular Inspections: Conduct routine inspections to identify any signs of wear, corrosion, or damage to the RTO components. This includes inspecting valves, dampers, fans, combustion chambers, heat exchangers, and ceramic media beds. Inspections help detect potential issues early and allow for timely repairs or replacements.

- Cleaning and Replacement of Components: Clean or replace components as needed to maintain proper functionality. This may include cleaning clogged or fouled heat exchanger surfaces, replacing damaged or worn-out valves and dampers, and periodically replacing the ceramic media beds if they become degraded or contaminated.

- Monitoring Operating Parameters: Regularly monitor and record operating parameters such as temperature, airflow, pressure differentials, and gas concentrations. Deviations from normal operating ranges can indicate potential problems or inefficiencies that require attention.

- Calibration of Instruments: Calibrate instruments and sensors used for monitoring and control purposes to ensure accurate measurement of parameters such as temperature, pressure, and flow rates. Proper calibration helps maintain reliable and precise operation of the RTO.

- Cleaning of Heat Recovery System: Clean the heat recovery system, including the heat exchanger surfaces, to remove any accumulated particulate matter or fouling. This ensures efficient heat transfer and prevents the buildup of deposits that can reduce the RTO’s performance.

- Compliance with Safety Standards: Adhere to safety standards and guidelines for working with the RTO. This includes proper lockout/tagout procedures during maintenance activities, wearing appropriate personal protective equipment, and following safety protocols to minimize risks to personnel and equipment.

- Documentation and Record-Keeping: Maintain comprehensive records of maintenance activities, inspections, repairs, and any modifications made to the RTO. Documentation helps track the equipment’s history, aids in troubleshooting, and provides a record of compliance with regulatory requirements.

It’s important to note that the specific maintenance requirements may vary depending on the RTO manufacturer’s recommendations, the design of the system, the operating conditions, and applicable regulatory requirements. Following the manufacturer’s guidelines, conducting regular inspections, and implementing a proactive maintenance program tailored to the specific RTO are crucial for ensuring its reliable operation and longevity.

editor by CX 2024-03-13