Maklumat Asas.

Model NO.

RTO

Punca Tarikan

Kawalan Pencemaran Udara

Kaedah Pemprosesan

Pembakaran

Tanda dagangan

RUIMA

asal usul

China

Kod HS

84213990

Penerangan Produk

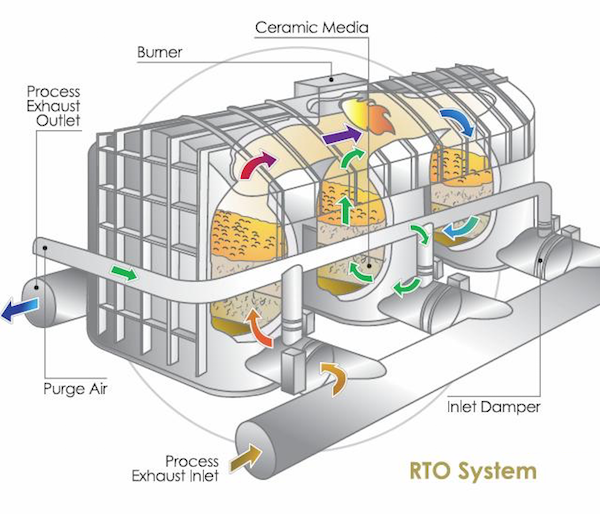

Pengoksida Terma Penjanaan Semula (RTO);

Teknik pengoksidaan yang paling banyak digunakan pada masa kini untuk

Pengurangan pelepasan VOC,; sesuai untuk merawat pelbagai pelarut dan proses.; Bergantung pada isipadu udara dan kecekapan penulenan yang diperlukan,; RTO datang dengan 2,; 3,; 5 atau 10 bilik.;

Kelebihan

Pelbagai VOC untuk dirawat

Kos penyelenggaraan yang rendah

Kecekapan Terma Tinggi

Tidak menjana sebarang pembaziran

Boleh disesuaikan untuk kecil,; aliran udara sederhana dan besar

Pemulihan Haba melalui pintasan jika kepekatan VOC melebihi titik auto-terma

Auto-terma dan Pemulihan Haba:;

Kecekapan Terma > 95%

Titik auto-terma pada 1.;2 – 1.;7 mgC/Nm3

Julat aliran udara dari 2,; 000 hingga 200,; 000m3/j

Kemusnahan VOC yang tinggi

Kecekapan penulenan biasanya melebihi 99%

Address: No 3 North Xihu (West Lake) Dis. Road, Xihu (West Lake) Dis., HangZhou, ZheJiang , China

Business Type: Manufacturer/Factory

Business Range: Manufacturing & Processing Machinery, Service

Management System Certification: ISO 14001, ISO 9001, OHSAS/ OHSMS 18001, QHSE

Main Products: Dryer, Extruder, Heater, Twin Screw Extruder, Electrochemical Corrosion Protection Equ, Screw, Mixer, Pelletizing Machine, Compressor, Pelletizer

Company Introduction: The Res. Inst of Chem. Mach of the Ministry of Chemical Industry was founded in ZheJiang in 1958, and moved to HangZhou in 1965.

The Res. Inst of Automation Kementerian Industri Kimia telah diasaskan di HangZhou pada tahun 1963.

Pada tahun 1997, Res. Inst. Daripada Chem. Mach Kementerian Industri Kimia dan Res. Inst. Automasi Kementerian Industri Kimia telah digabungkan untuk menjadi Res. Inst of Chemical Machinery and Automation of Kementerian Industri Kimia.

Pada tahun 2000, Res. Inst of Chemical Machinery and Automation of Ministry of ChemicalIndustry menyelesaikan transformasinya kepada perusahaan dan didaftarkan sebagai CHINAMFG Instituteof Chemical Machinery and Automation.

Institut Tianhua mempunyai institusi subordinat berikut:

Pusat Penyeliaan dan Pemeriksaan Kualiti Peralatan Kimia di HangZhou, Wilayah ZheJiang

Institut Peralatan HangZhou di HangZhou, Wilayah ZheJiang;

Institut Automasi di HangZhou, Wilayah ZheJiang;

HangZhou Ruima Chemical Machinery Co Ltd di HangZhou, Wilayah ZheJiang;

HangZhou Ruide Drying Technology Co Ltd di HangZhou, Wilayah ZheJiang;

HangZhouLantai Plastics Machinery Co Ltd di HangZhou, Wilayah ZheJiang;

ZheJiang Airuike Automation Technology Co Ltd di HangZhou, Wilayah ZheJiang;

Institut Jentera Kimia dan automasi HangZhou United dan Institut Relau Industri Petrokimia HangZhou United diasaskan oleh Institut CHINAMFG dan Sinopec.

Institut Tianhua mempunyai kawasan pekerjaan seluas 80 000m2 dan jumlah aset 1 Yuan (RMB). Nilai keluaran tahunan ialah 1 Yuan (RMB).

Institut Tianhua mempunyai kira-kira 916 pekerja, 75% daripada mereka adalah kakitangan profesional. Antaranya ialah 23 profesor, 249jurutera kanan, 226 jurutera. 29 profesor dan jurutera kanan menikmati subsidi khas negara, Kepada 5 orang gelaran Pakar Pertengahan Umur dan Muda dengan Sumbangan Cemerlang kepada RR China dianugerahkan

What is the role of heat recovery in a regenerative thermal oxidizer?

Heat recovery plays a crucial role in the operation of a regenerative thermal oxidizer (RTO) by improving its energy efficiency and reducing fuel consumption. The primary function of heat recovery in an RTO is to capture and transfer heat from the treated exhaust gases to the incoming untreated gases, minimizing the need for additional external heating.

Here’s a closer look at the role of heat recovery in an RTO:

- Energy Efficiency: RTOs are designed to achieve high thermal efficiency by utilizing the heat recovery principle. The heat recovery system consists of heat exchangers or beds filled with ceramic media, such as structured ceramic blocks or random ceramic saddles. These beds alternate between the exhaust gas flow and the incoming untreated gas flow.

- Heat Transfer Process: During operation, the hot exhaust gases from the industrial process flow through one bed of the heat exchanger, transferring heat to the ceramic media. The media absorbs the heat, and the temperature of the exhaust gases decreases. Simultaneously, the cooler incoming untreated gas flows through the other bed, where it absorbs the heat stored in the media, preheating the gas before it enters the combustion chamber.

- Bed Switching: The direction of gas flow through the beds is periodically switched using valves or dampers. This switching operation allows the RTO to alternate between different beds, ensuring continuous heat recovery and thermal oxidation of the pollutants. By efficiently recovering and reusing heat from the exhaust gases, the RTO reduces the amount of external fuel needed to maintain the required operating temperature.

- Reduction in Fuel Consumption: The heat recovery mechanism in an RTO significantly reduces the fuel consumption compared to other types of oxidizers. The preheating of the incoming untreated gas stream reduces the energy required to raise the temperature of the gas to the combustion temperature, resulting in lower fuel usage and operational costs.

- Economic and Environmental Benefits: Heat recovery in RTOs offers economic benefits by reducing energy costs and improving the overall sustainability of the facility. By minimizing fuel consumption, heat recovery contributes to a lower carbon footprint and helps meet environmental goals by reducing greenhouse gas emissions associated with the combustion process.

The effectiveness of heat recovery in an RTO depends on factors such as the design of the heat exchanger, the choice of ceramic media, the flow rates of the exhaust gases and incoming untreated gas, and the temperature differential between the two streams. Proper sizing and optimization of the heat recovery system are essential to ensure efficient heat transfer and maximize energy savings.

Overall, heat recovery is a key component in the design of an RTO, allowing for improved energy efficiency, reduced fuel consumption, and environmental sustainability.

Can regenerative thermal oxidizers handle corrosive exhaust gases?

Regenerative thermal oxidizers (RTOs) can be designed to handle corrosive exhaust gases effectively. However, the ability of an RTO to handle corrosive gases depends on several factors, including the choice of construction materials, operating conditions, and the specific corrosive nature of the exhaust gases. Here are some key points regarding the handling of corrosive exhaust gases in RTOs:

- Material Selection: The selection of appropriate construction materials is crucial when dealing with corrosive gases. RTOs can be constructed using materials that offer high resistance to corrosion, such as stainless steel, corrosion-resistant alloys (e.g., Hastelloy, Inconel), or coated materials. The choice of materials depends on the specific corrosive compounds present in the exhaust gases and their concentrations.

- Corrosion-Resistant Coatings: In addition to selecting corrosion-resistant materials, applying protective coatings can enhance the resistance of the RTO components to corrosive gases. Coatings such as ceramic coatings, epoxy coatings, or acid-resistant paints can provide an extra layer of protection against corrosion.

- Temperature Control: Maintaining appropriate operating temperatures in the RTO can help mitigate the corrosive effects of the exhaust gases. Higher temperatures can promote the decomposition of corrosive compounds, reducing their corrosive potential. Additionally, operating at higher temperatures can enhance the self-cleaning effect and prevent the accumulation of corrosive deposits on the surfaces.

- Gas Conditioning: Prior to entering the RTO, the exhaust gases can undergo gas conditioning processes to reduce their corrosive nature. This may involve pre-treatment methods such as scrubbing or neutralization to remove or neutralize corrosive compounds and reduce their concentration.

- Monitoring and Maintenance: Regular monitoring of the RTO performance and periodic maintenance are essential to ensure the effective handling of corrosive exhaust gases. Monitoring systems can track variables such as temperature, pressure, and gas composition to detect any deviations that may indicate corrosion-related issues. Proper maintenance, including cleaning and inspection of the components, helps identify and address any corrosion concerns in a timely manner.

It is important to note that the corrosiveness of exhaust gases can vary significantly depending on the specific industrial process and the pollutants involved. Therefore, when designing an RTO for handling corrosive gases, it is advisable to consult with experienced engineers or RTO manufacturers who can provide guidance on the appropriate design considerations and material selection.

By employing suitable materials, coatings, temperature control, gas conditioning, and maintenance practices, RTOs can effectively handle corrosive exhaust gases while ensuring their long-term performance and durability.

Bagaimanakah pengoksida terma regeneratif berfungsi?

A regenerative thermal oxidizer (RTO) operates through a cyclical process that involves several key steps. Here’s a detailed explanation of how an RTO works:

1. Plenum Masuk: Gas ekzos yang mengandungi bahan pencemar memasuki RTO melalui plenum masuk.

2. Katil Penukar Haba: RTO mengandungi berbilang katil penukar haba yang diisi dengan media penyimpanan haba, biasanya bahan seramik atau pembungkusan berstruktur. Katil penukar haba disusun secara berpasangan.

3. Injap Kawalan Aliran: Injap kawalan aliran mengarahkan aliran udara dan mengawal arah gas ekzos melalui RTO.

4. Kebuk Pembakaran: Gas ekzos, kini diarahkan ke dalam kebuk pembakaran, dipanaskan pada suhu tinggi, biasanya antara 1400°F (760°C) dan 1600°F (870°C). Julat suhu ini memastikan pengoksidaan haba yang berkesan bagi bahan pencemar.

5. Kemusnahan VOC: The high temperature in the combustion chamber causes the volatile organic compounds (VOCs) and other contaminants to react with oxygen, resulting in their thermal decomposition or oxidation. This process breaks down the pollutants into water vapor, carbon dioxide, and other harmless gases.

6. Pemulihan Haba: Gas-gas panas dan tulen yang meninggalkan kebuk pembakaran melalui plenum alir keluar dan mengalir melalui katil penukar haba yang berada dalam fasa operasi yang bertentangan. Media penyimpanan haba di dalam katil menyerap haba daripada gas yang keluar, yang memanaskan gas ekzos yang masuk.

7. Penukaran Kitaran: Selepas selang masa tertentu, injap kawalan aliran menukar arah aliran udara, membenarkan katil penukar haba yang memanaskan gas masuk kini menerima gas panas daripada kebuk pembakaran. Kitaran kemudian berulang, memastikan operasi berterusan dan cekap.

Kelebihan pengoksida terma regeneratif:

RTO menawarkan beberapa kelebihan dalam kawalan pencemaran udara industri:

1. Kecekapan Tinggi: RTO boleh mencapai kecekapan pemusnahan yang tinggi, biasanya melebihi 95%, dengan berkesan menyingkirkan pelbagai jenis bahan pencemar.

2. Pemulihan Tenaga: Mekanisme pemulihan haba dalam RTO membolehkan penjimatan tenaga yang ketara. Pemanasan awal gas yang masuk mengurangkan penggunaan bahan api yang diperlukan untuk pembakaran, menjadikan RTO cekap tenaga.

3. Keberkesanan kos: Walaupun pelaburan modal awal untuk RTO boleh menjadi ketara, penjimatan kos operasi jangka panjang melalui pemulihan tenaga dan kecekapan pemusnahan yang tinggi menjadikannya penyelesaian yang kos efektif sepanjang jangka hayat sistem.

4. Pematuhan Alam Sekitar: RTO direka bentuk untuk memenuhi peraturan pelepasan yang ketat dan membantu industri mematuhi piawaian dan permit kualiti udara.

5. serba boleh: RTO boleh mengendalikan pelbagai volum ekzos proses dan kepekatan pencemar, menjadikannya sesuai untuk pelbagai aplikasi perindustrian.

Secara keseluruhannya, pengoksida terma regeneratif beroperasi dengan menggunakan pemulihan haba, pembakaran suhu tinggi, dan kawalan aliran kitaran untuk mengoksidakan bahan pencemar dengan berkesan dan mencapai kecekapan pemusnahan yang tinggi sambil meminimumkan penggunaan tenaga.

editor by CX 2023-10-21