Informações básicas.

Modelo NO.

RTO

Pullution Sources

Air Pollution Control

Processing Methods

Combustion

Marca registrada

RUIMA

Origem

China

Código HS

84213990

Descrição do produto

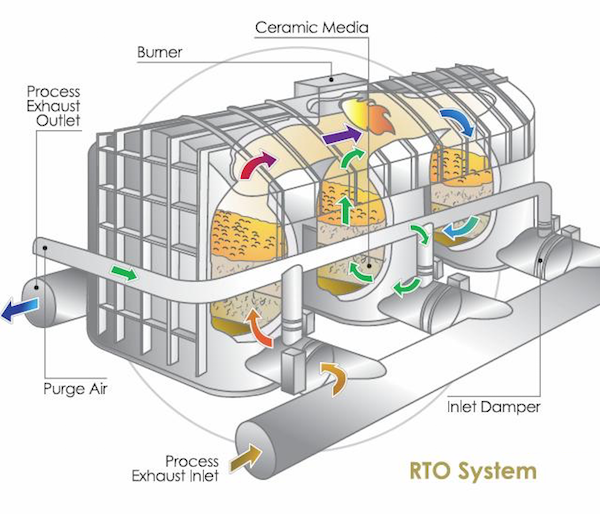

Regenerative Thermal Oxidizer (RTO);

The most widely used oxidation technique nowadays for

VOC emission reduction,; suitable for treating a wide range of solvents and processes.; Depending on air volume and required purification efficiency,; a RTO comes with 2,; 3,; 5 or 10 chambers.;

Advantages

Wide range of VOC’s to be treated

Low maintenance cost

High Thermal Efficiency

Does not generate any waste

Adaptable for small,; medium and large air flows

Heat Recovery via bypass if VOCs concentration exceed the auto-thermal point

Auto-thermal and Heat Recovery:;

Thermal Efficiency > 95%

Auto-thermal point at 1.;2 – 1.;7 mgC/Nm3

Air flow range from 2,; 000 up to 200,; 000m3/h

High VOC’s destruction

The purification efficiency is normally in excess of 99%

Address: No 3 North Xihu (West Lake) Dis. Road, Xihu (West Lake) Dis., HangZhou, ZheJiang , China

Tipo de negócio: Fabricante/Fábrica

Business Range: Manufacturing & Processing Machinery, Service

Management System Certification: ISO 14001, ISO 9001, OHSAS/ OHSMS 18001, QHSE

Main Products: Dryer, Extruder, Heater, Twin Screw Extruder, Electrochemical Corrosion Protection Equ, Screw, Mixer, Pelletizing Machine, Compressor, Pelletizer

Company Introduction: The Res. Inst of Chem. Mach of the Ministry of Chemical Industry was founded in ZheJiang in 1958, and moved to HangZhou in 1965.

The Res. Inst of Automation of the Ministry of Chemical Industry was founded in HangZhou in 1963.

In 1997, the Res. Inst. Of Chem. Mach of the Ministry of Chemical Industry and the Res. Inst. Of Automation of the Ministry of Chemical Industry were combined to become the Res. Inst of Chemical Machinery and Automation of the Ministry of Chemical Industry.

In 2000, the Res. Inst of Chemical Machinery and Automation of the Ministry of ChemicalIndustry completed its transformation to enterprise and registered as CHINAMFG Instituteof Chemical Machinery and Automation.

Tianhua Institute has the following subordinated institutions:

Supervision and Inspection Center of the Quality of Chemical Equipments in HangZhou, ZheJiang Province

HangZhou Equipment Institute in HangZhou, ZheJiang Province;

Automation Institute in HangZhou, ZheJiang Province;

HangZhou Ruima Chemical Machinery Co Ltd in HangZhou, ZheJiang Province;

HangZhou Ruide Drying Technology Co Ltd in HangZhou, ZheJiang Province;

HangZhouLantai Plastics Machinery Co Ltd in HangZhou, ZheJiang Province;

ZheJiang Airuike Automation Technology Co Ltd in HangZhou, ZheJiang Province;

The HangZhou United Institute of Chemical Machinery and automation and the HangZhou United Institute of Petrochemical Industry Furnaces were founded by CHINAMFG Institute and the Sinopec.

Tianhua Institute has an occupation area of 80 000m2 and a total asset of 1 Yuan (RMB). The annual output value is 1 Yuan (RMB).

Tianhua Institute has about 916 employees, 75% of them are professional personnel. Among them are 23 professors, 249senior engineers, 226 engineers. 29 professors and senior engineers enjoy national special subsidy, On 5 people the title of Middle-aged and Young Specialist with Outstanding Contribution to the P. R. China are conferred

What is the role of heat recovery in a regenerative thermal oxidizer?

Heat recovery plays a crucial role in the operation of a regenerative thermal oxidizer (RTO) by improving its energy efficiency and reducing fuel consumption. The primary function of heat recovery in an RTO is to capture and transfer heat from the treated exhaust gases to the incoming untreated gases, minimizing the need for additional external heating.

Here’s a closer look at the role of heat recovery in an RTO:

- Eficiência energética: RTOs are designed to achieve high thermal efficiency by utilizing the heat recovery principle. The heat recovery system consists of heat exchangers or beds filled with ceramic media, such as structured ceramic blocks or random ceramic saddles. These beds alternate between the exhaust gas flow and the incoming untreated gas flow.

- Heat Transfer Process: During operation, the hot exhaust gases from the industrial process flow through one bed of the heat exchanger, transferring heat to the ceramic media. The media absorbs the heat, and the temperature of the exhaust gases decreases. Simultaneously, the cooler incoming untreated gas flows through the other bed, where it absorbs the heat stored in the media, preheating the gas before it enters the combustion chamber.

- Bed Switching: The direction of gas flow through the beds is periodically switched using valves or dampers. This switching operation allows the RTO to alternate between different beds, ensuring continuous heat recovery and thermal oxidation of the pollutants. By efficiently recovering and reusing heat from the exhaust gases, the RTO reduces the amount of external fuel needed to maintain the required operating temperature.

- Reduction in Fuel Consumption: The heat recovery mechanism in an RTO significantly reduces the fuel consumption compared to other types of oxidizers. The preheating of the incoming untreated gas stream reduces the energy required to raise the temperature of the gas to the combustion temperature, resulting in lower fuel usage and operational costs.

- Economic and Environmental Benefits: Heat recovery in RTOs offers economic benefits by reducing energy costs and improving the overall sustainability of the facility. By minimizing fuel consumption, heat recovery contributes to a lower carbon footprint and helps meet environmental goals by reducing greenhouse gas emissions associated with the combustion process.

The effectiveness of heat recovery in an RTO depends on factors such as the design of the heat exchanger, the choice of ceramic media, the flow rates of the exhaust gases and incoming untreated gas, and the temperature differential between the two streams. Proper sizing and optimization of the heat recovery system are essential to ensure efficient heat transfer and maximize energy savings.

Overall, heat recovery is a key component in the design of an RTO, allowing for improved energy efficiency, reduced fuel consumption, and environmental sustainability.

Can regenerative thermal oxidizers handle corrosive exhaust gases?

Regenerative thermal oxidizers (RTOs) can be designed to handle corrosive exhaust gases effectively. However, the ability of an RTO to handle corrosive gases depends on several factors, including the choice of construction materials, operating conditions, and the specific corrosive nature of the exhaust gases. Here are some key points regarding the handling of corrosive exhaust gases in RTOs:

- Material Selection: The selection of appropriate construction materials is crucial when dealing with corrosive gases. RTOs can be constructed using materials that offer high resistance to corrosion, such as stainless steel, corrosion-resistant alloys (e.g., Hastelloy, Inconel), or coated materials. The choice of materials depends on the specific corrosive compounds present in the exhaust gases and their concentrations.

- Corrosion-Resistant Coatings: In addition to selecting corrosion-resistant materials, applying protective coatings can enhance the resistance of the RTO components to corrosive gases. Coatings such as ceramic coatings, epoxy coatings, or acid-resistant paints can provide an extra layer of protection against corrosion.

- Temperature Control: Maintaining appropriate operating temperatures in the RTO can help mitigate the corrosive effects of the exhaust gases. Higher temperatures can promote the decomposition of corrosive compounds, reducing their corrosive potential. Additionally, operating at higher temperatures can enhance the self-cleaning effect and prevent the accumulation of corrosive deposits on the surfaces.

- Gas Conditioning: Prior to entering the RTO, the exhaust gases can undergo gas conditioning processes to reduce their corrosive nature. This may involve pre-treatment methods such as scrubbing or neutralization to remove or neutralize corrosive compounds and reduce their concentration.

- Monitoring and Maintenance: Regular monitoring of the RTO performance and periodic maintenance are essential to ensure the effective handling of corrosive exhaust gases. Monitoring systems can track variables such as temperature, pressure, and gas composition to detect any deviations that may indicate corrosion-related issues. Proper maintenance, including cleaning and inspection of the components, helps identify and address any corrosion concerns in a timely manner.

It is important to note that the corrosiveness of exhaust gases can vary significantly depending on the specific industrial process and the pollutants involved. Therefore, when designing an RTO for handling corrosive gases, it is advisable to consult with experienced engineers or RTO manufacturers who can provide guidance on the appropriate design considerations and material selection.

By employing suitable materials, coatings, temperature control, gas conditioning, and maintenance practices, RTOs can effectively handle corrosive exhaust gases while ensuring their long-term performance and durability.

Como funciona um oxidante térmico regenerativo?

A regenerative thermal oxidizer (RTO) operates through a cyclical process that involves several key steps. Here’s a detailed explanation of how an RTO works:

1. Pleno de entrada: Os gases de escape contendo poluentes entram no RTO através do plenum de admissão.

2. Leitos de troca de calor: O RTO contém vários leitos de trocadores de calor preenchidos com meios de armazenamento de calor, tipicamente materiais cerâmicos ou empacotamento estruturado. Os leitos de trocadores de calor são dispostos em pares.

3. Válvulas de controle de fluxo: As válvulas de controle de fluxo direcionam o fluxo de ar e controlam a direção dos gases de escape através do RTO.

4. Câmara de combustão: Os gases de exaustão, agora direcionados para a câmara de combustão, são aquecidos a uma alta temperatura, tipicamente entre 1400°F (760°C) e 1600°F (870°C). Essa faixa de temperatura garante oxidação térmica efetiva dos poluentes.

5. Destruição de COV: The high temperature in the combustion chamber causes the volatile organic compounds (VOCs) and other contaminants to react with oxygen, resulting in their thermal decomposition or oxidation. This process breaks down the pollutants into water vapor, carbon dioxide, and other harmless gases.

6. Recuperação de calor: Os gases quentes e purificados que saem da câmara de combustão passam pelo plenum de saída e fluem pelos leitos do trocador de calor que estão na fase oposta de operação. O meio de armazenamento de calor nos leitos absorve o calor dos gases de saída, o que pré-aquece os gases de exaustão de entrada.

7. Troca de ciclo: Após um intervalo de tempo específico, as válvulas de controle de fluxo trocam a direção do fluxo de ar, permitindo que os leitos do trocador de calor que estavam pré-aquecendo os gases de entrada agora recebam os gases quentes da câmara de combustão. O ciclo então se repete, garantindo uma operação contínua e eficiente.

Vantagens de um oxidante térmico regenerativo:

Os RTOs oferecem diversas vantagens no controle da poluição do ar industrial:

1. Alta eficiência: Os RTOs podem atingir altas eficiências de destruição, normalmente acima de 95%, removendo efetivamente uma ampla gama de poluentes.

2. Recuperação de energia: O mecanismo de recuperação de calor em RTOs permite economias significativas de energia. O pré-aquecimento dos gases de entrada reduz o consumo de combustível necessário para a combustão, tornando os RTOs energeticamente eficientes.

3. Custo-efetividade: Embora o investimento de capital inicial para um RTO possa ser significativo, a economia de custos operacionais a longo prazo por meio da recuperação de energia e altas eficiências de destruição o tornam uma solução econômica ao longo da vida útil do sistema.

4. Conformidade ambiental: Os RTOs são projetados para atender a regulamentações rigorosas de emissões e ajudar as indústrias a cumprir os padrões e licenças de qualidade do ar.

5. Versatilidade: Os RTOs podem lidar com uma ampla gama de volumes de exaustão de processo e concentrações de poluentes, tornando-os adequados para diversas aplicações industriais.

No geral, um oxidante térmico regenerativo opera utilizando recuperação de calor, combustão de alta temperatura e controle de fluxo cíclico para oxidar poluentes de forma eficaz e atingir altas eficiências de destruição, minimizando o consumo de energia.

editor by CX 2023-10-21