RTO for Metal Coatings

介紹

Regenerative Thermal Oxidizers (RTOs) have become a popular solution for the metal coating industry. The process involves using high temperatures to oxidize volatile organic compounds (VOCs) that are released during the coating process. RTOs have proven to be an effective method for reducing VOC emissions and meeting regulatory requirements.

How RTO Works for Metal Coatings

RTOs use a two-chamber system to oxidize VOCs. The first chamber heats up the VOC-laden air to a high temperature, which causes the VOCs to oxidize. The second chamber releases clean air into the environment while the first chamber continues to heat and oxidize VOCs. The process is cyclic, meaning that the heated air from the second chamber is used to preheat the air in the first chamber. This helps to reduce energy costs and increase efficiency.

Advantages of RTO for Metal Coatings

RTOs have several advantages when it comes to controlling VOC emissions in the metal coating industry:

- RTOs are highly effective at destroying VOCs, resulting in fewer emissions and a cleaner environment.

- RTOs are energy-efficient, which can lead to cost savings for companies that use them.

- RTOs are easy to operate and maintain, making them a convenient option for busy factories and warehouses.

- RTOs are highly customizable, which means they can be tailored to meet the specific needs of each coating application.

Disadvantages of RTO for Metal Coatings

While RTOs offer many advantages, there are also some potential disadvantages to consider:

- The initial cost of installing an RTO can be high, which may be a barrier for some businesses.

- RTOs require a significant amount of energy to operate, which can lead to higher utility bills.

- Some RTOs can be noisy, which may be a concern for workers and nearby residents.

- RTOs require regular maintenance to ensure optimal performance, which can be time-consuming and costly.

Applications of RTO for Metal Coatings

RTOs are used in a wide range of metal coating applications, including:

- Painting and powder coating of metal parts and components

- Surface treatment of metal products

- Coating of metal roofing materials

- Galvanizing and electroplating of metal items

In each of these applications, RTOs have proven to be an effective method for reducing VOC emissions and ensuring compliance with environmental regulations.

結論

In summary, RTOs have become a popular solution for the metal coating industry due to their ability to reduce VOC emissions and meet regulatory requirements. While there are some potential disadvantages to consider, the advantages of RTOs make them a valuable option for businesses looking to control VOC emissions and maintain a clean environment. As the demand for sustainable practices continues to grow, RTOs will likely become an increasingly important part of the metal coating industry.

公司簡介

We are a high-end equipment manufacturing enterprise specializing in comprehensive treatment of volatile organic compound (VOC) waste gas and carbon reduction and energy-saving technologies. Our core technologies include thermal energy, combustion, sealing, and control. We have the capabilities for temperature field simulation, air flow simulation modeling, ceramic heat storage material performance, molecular sieve material selection, and VOC high-temperature incineration oxidation testing.

Team Advantage

We have a RTO technology R&D center and waste gas carbon reduction engineering technology center in Xi’an, as well as a 30,000 square meter production base in Yangling. We are a leading manufacturer of RTO equipment and molecular sieve wheel equipment in terms of production and sales volume globally. Our core technical team comes from the Aerospace Liquid Rocket Engine Research Institute (Aerospace Institute) with over 360 employees, including over 60 R&D technology backbones, 3 senior engineers, 6 engineers, and 45 thermodynamics doctors.

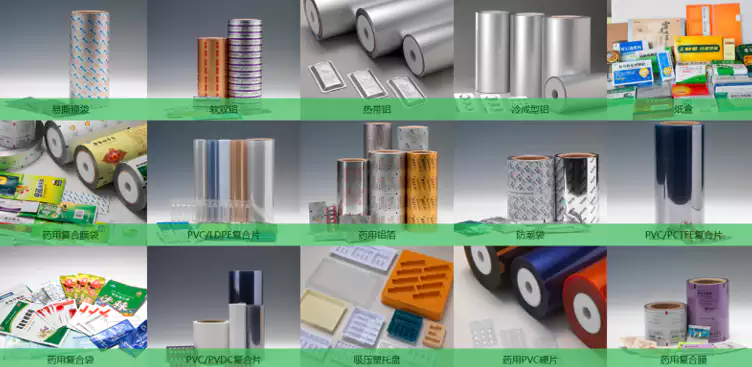

核心產品

Our core products include the Rotary Valve Heat Storage Oxidation Incinerator (RTO) and molecular sieve adsorption concentration wheel. With our expertise in environmental protection and thermal energy system engineering, we can provide customers with comprehensive solutions for industrial waste gas treatment and carbon reduction with various operating conditions.

Certifications and Qualifications

Our company has obtained the following certifications and qualifications: Knowledge Intellectual Property Management System Certification, Quality Management System Certification, Environmental Management System Certification, Construction Industry Enterprise Qualification, High-tech Enterprise, Rotary Heat Storage Oxidation Furnace Rotary Valve Patent, Rotary Heat Storage Incineration Equipment Patent, and Disc Zeolite Wheel Patent.

Choosing the Right RTO for the Coating Industry

- 確定廢氣的特性

- 了解當地法規和排放標準

- 評估能源效率

- 考慮維

- 預算和成本分析

- 選擇適當的 RTO 類型

- 考慮環境和安全因素

- 效能測試與驗證

Regenerative Thermal Oxidizers Service Process

- 初步諮詢、現場考察、需求分析

- 解決方案設計、模擬和審查

- 客製化生產、品質控制和工廠測試

- 現場安裝、調試、培訓服務

- 定期維護、技術支援、備件供應

We are a one-stop solution for RTO, providing tailor-made RTO solutions for customers. Our professional team is dedicated to delivering the best outcomes.

Success Stories of RTO for the Coating Industry

- Case 1: A company in Shanghai that specializes in diffusion films, prism films, micro-perforated films, and solar films. The project includes a 40,000 airflow RTO in phase one and a 50,000 airflow RTO in phase two.

- Case 2: A company in Guangdong that produces transfer paper, transfer film, electrolytic aluminum, polyester film, window film, and protective films. The total waste gas volume is 70,000 m3/h, and the equipment achieved emission standards after completion.

- Case 46: A company in Zhuhai that produces wet lithium battery separators. The system has been running faultlessly since its installation.

作者:米婭