基本訊息

型號

Amazing RTO

類型

Incinerator

Energy Saving

100

Easy for Operation

100

High Efficiency

100

Less Maintenance

100

商標

Bjamazing

運輸套餐

Overseas Wooden

Specification

180*24

起源

China

HS Code

8416100000

產品描述

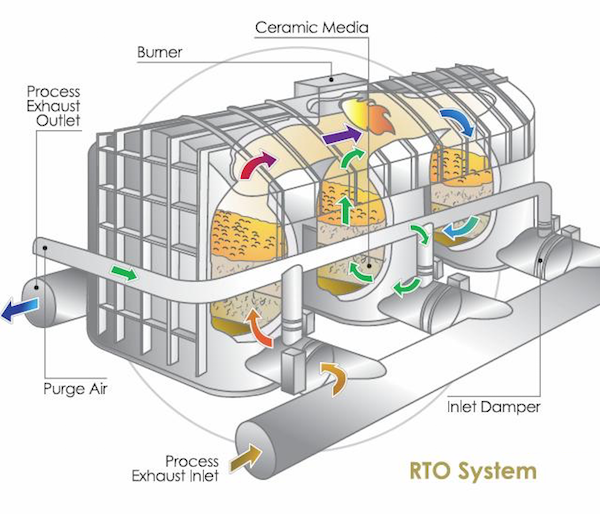

RTO

蓄熱式熱氧化器

Compared with traditional catalytic combustion,; direct thermal oxidizer,; RTO has the merits of high heating efficiency,; low operation cost,; and the ability to treat large flux low concentration waste gas.; When VOCs concentration is high,; secondary heat recycle can be realized,; which will greatly reduce the operation cost.; Because RTO can preheat the waste gas by levels through ceramic heat accumulator,; which could make the waste gas to be completely heated and cracked with no dead corner(treatment efficiency>99%);,;which reduce the NOX in the Exhausting gas,; if the VOC density >1500mg/Nm3,; when the waste gas reach cracking area,; it has been heated up to cracking temperature by heat accumulator,; the burner will be closed under this condition.;

RTO can be devided into chamber type and rotary type according to difference operation mode.; Rotary type RTO has advantages in system pressure,; temperature stability,; investment amount,; etc

| RTO types | Efficiency | Pressure change (mmAq); | 尺寸 | (max);Treatment volume | |

| Treatment efficiency | Heat recycle efficiency | ||||

| Rotary type RTO | 99 % | 97 % | 0-4 | small(1 time); | 50000Nm3/h |

| Three chamber type RTO | 99 % | 97 % | 0-10 | Large (1.;5times); | 100000Nm3/h |

| Two chamber type RTO | 95 % | 95 % | 0-20 | middle(1.;2times); | 100000Nm3/h |

Regenerative Thermal Oxidizer,; Regenerative Thermal Oxidizer,; Regenerative Thermal Oxidizer,; Thermal Oxidizer,; Thermal Oxidizer,; Thermal Oxidizer,; oxidizer,; oxidizer,; oxidizer,; incinerator,; incinerator,; incinerator,; waste gas treatment,; waste gas treatment,; waste gas treatment,; VOC treatment,; VOC treatment,; VOC treatment,; RTO,; RTO,; RTO,; RTO,; RTO,; RTO

Address: 8 floor, E1, Pinwei building, Dishengxi road, Yizhuang, ZheJiang , China

業務類型: 製造商/工廠, 貿易公司

Business Range: Electrical & Electronics, Industrial Equipment & Components, Manufacturing & Processing Machinery, Metallurgy, Mineral & Energy

Management System Certification: ISO 9001, ISO 14001

Main Products: Rto, Color Coating Line, Galvanizing Line, Air Knife, Spares for Processing Line, Coater, Independent Equipments, Sink Roll, Revamping Project, Blower

Company Introduction: ZheJiang Amazing Science & Technology Co., Ltd is a thriving Hi-tech company, located in ZheJiang Economic and Technological Development Area(BDA). Adhering to the concept of Realistic, Innovative, Focused and Efficient, our company mainly serve the waste gas treatment (VOCs) Industry and metallurgical equipment of China and even whole world. We have advanced technology and rich experience in VOCs waste gas treatment project, the reference of which has been successfully applied to the industry of coating, rubber, electronic, printing, etc. We also have years of technology accumulation in the research and manufacturing of flat steel processing line, and possess nearly 100 of application example.

Our company focus on the research, design, manufacturing, installation and commissioning of VOCs organic waste gas treatment system and the revamping and updating project for energy saving and environmental protection of flat steel processing line. We can provide customers the complete solutions for environmental protection, energy saving, product quality improvement and other aspects.

We are also engaged in various spares and independent equipment for color coating line, galvanizing line, pickling line, like roller, coupler, heat exchanger, recuperator, air knife, blower, welder, tension leveler, skin pass, expansion joint, shear, jointer, stitcher, burner, radiant tube, gear motor, reducer, etc.

Are there any incentives or grants available for installing regenerative thermal oxidizers?

Yes, there are various incentives and grants available that can help offset the cost of installing regenerative thermal oxidizers (RTOs) and other emission control technologies. These incentives are typically offered by government agencies at the local, regional, and national levels to promote environmental sustainability, air quality improvement, and compliance with emissions regulations. However, the availability and specific details of these incentives may vary depending on the location and the specific program.

Here are some examples of incentives and grants that may be available:

- Energy Efficiency Grants: Many government agencies and utility companies offer grants and financial incentives to encourage energy efficiency measures, including the installation of energy-efficient equipment like RTOs. These grants can help offset a portion of the installation costs and may be based on factors such as energy savings, reduction in greenhouse gas emissions, or specific environmental objectives.

- Environmental Grant Programs: Some governmental organizations or environmental foundations provide grants specifically targeted at reducing emissions and improving air quality. These grants may be available for industries or businesses that invest in emission control technologies, such as RTOs, to help them comply with regulations and improve their environmental performance.

- Tax Incentives and Credits: Certain jurisdictions offer tax incentives or credits to businesses or industries that invest in environmentally friendly technologies. These incentives can significantly reduce the overall cost of installing an RTO. Examples include tax credits for energy-efficient equipment, accelerated depreciation allowances, or exemptions from sales tax on eligible equipment purchases.

- Industry-Specific Programs: Some industries or sectors may have specific grant programs or incentives tailored to their unique environmental challenges. These programs may provide financial assistance for emission control projects, including the installation of RTOs, within those industries.

- Research and Development Funding: Government agencies or research organizations often provide funding opportunities for the development and implementation of innovative emission control technologies. Businesses or research institutions involved in developing advanced RTO designs or improving RTO efficiency may be eligible for research grants or funding support.

To explore the availability of incentives and grants for installing RTOs, it is recommended to contact local environmental agencies, energy efficiency programs, or business development organizations. These entities can provide information on specific incentive programs, eligibility criteria, application procedures, and any deadlines or limitations associated with the grants.

It’s important to note that incentive programs may change over time, and their availability may depend on factors such as funding allocations and government policies. Therefore, it is advisable to stay updated with the latest information and consult with relevant authorities to determine the current incentives available for installing RTOs.

再生熱氧化器與生物過濾器的性能相比如何?

蓄熱式熱氧化器(RTO)和生物過濾器都是廣泛使用的空氣污染物處理技術,但它們的工作原理和性能特徵有所不同。以下是 RTO 和生物過濾器的性能比較:

| 性能方面 | 蓄熱式熱氧化器 (RTO) | 生物過濾器 |

|---|---|---|

| 排放去除效率 | RTO 在去除揮發性有機化合物 (VOC) 和有害空氣污染物 (HAP) 方面非常有效率。他們對這些污染物的破壞效率可達 95% 以上。 | 生物過濾器還有可能對某些揮發性有機化合物和有氣味的化合物實現高去除效率。然而,它們的性能可能會根據生物過濾器中的特定污染物和微生物活性而變化。 |

| 適用性 | RTO 用途廣泛,可以處理多種污染物,包括 VOC、HAP 和有味化合物。它們非常適合高流量和高污染物濃度。 | 生物過濾器在處理有氣味的化合物和某些揮發性有機化合物方面特別有效。它們通常用於廢水處理設施、堆肥作業和農業設施等應用。 |

| 能源消耗 | RTO 需要大量能量才能達到並維持氧化的高工作溫度。它們依靠燃料燃燒或外部熱源來獲取所需的熱能。 | 生物過濾器被認為是低能耗系統,因為它們依靠微生物的自然生物活性來分解污染物。它們通常不需要外部加熱或燃料消耗。 |

| 維護 | RTO 通常需要定期維護和監控以確保正常運作。這包括檢查、熱交換介質的清潔以及組件的潛在維修或更換。 | 生物過濾器需要定期維護以優化其性能。這可能涉及監測和調整濕度水平、控制溫度以及偶爾更換過濾介質或添加微生物接種劑。 |

| 資本和營運成本 | 與生物過濾器相比,RTO 由於其複雜的設計、專用材料和能源密集型操作,通常具有更高的資本成本。營運成本包括燃料消耗或暖氣用電。 | 與 RTO 相比,生物過濾器的資本成本通常較低。它們設計更簡單,並且不需要燃料消耗。然而,營運成本可能包括定期更換過濾介質和潛在的氣味控制措施。 |

值得注意的是,選擇合適的技術取決於多種因素,例如待處理的特定污染物、製程條件、監管要求和特定場地的考慮因素。諮詢環境工程師或空氣污染控制專家可以幫助確定最適合特定應用的技術。

綜上所述,RTO 和生物過濾器具有不同的性能特徵,RTO 具有去除效率高、通用性強、適合高流量和高濃度應用的優點,而生物過濾器對有氣味的化合物有效,能耗低,且資本通常較低成本。

What are the benefits of using a regenerative thermal oxidizer?

A regenerative thermal oxidizer (RTO) is an advanced air pollution control technology used in industrial processes to remove volatile organic compounds (VOCs), hazardous air pollutants (HAPs), and other harmful emissions. The use of an RTO offers several benefits:

1. High Destruction Efficiency: RTOs are known for their high destruction efficiency, typically achieving over 99% destruction of VOCs and HAPs. This effectiveness ensures that the majority of harmful pollutants are eliminated, resulting in cleaner air emissions and compliance with environmental regulations.

2. Energy Efficiency: RTOs are designed to be energy-efficient systems. They utilize a regenerative process that recovers and preheats the incoming process air by capturing and transferring heat from the outgoing exhaust stream. This heat recovery mechanism significantly reduces the energy consumption of the system, making RTOs a cost-effective solution for air pollution control.

3. Cost Savings: The energy efficiency of RTOs translates into cost savings for industrial operations. By reducing fuel consumption and operating costs, businesses can achieve long-term financial benefits. Additionally, the high destruction efficiency of RTOs eliminates the need for additional downstream pollution control equipment, reducing capital and maintenance expenses.

4. Thermal Self-Sustainability: RTOs have the unique ability to sustain their operating temperature without the need for external fuel sources. Once the system reaches the desired operating temperature, the heat recovery process maintains the necessary thermal energy for oxidation. This self-sustainability reduces reliance on external fuel, enhances system reliability, and minimizes operational downtime.

5. Flexibility and Adaptability: RTOs are versatile and can be designed to accommodate a wide range of process exhaust volumes and pollutant concentrations. They can handle varying flow rates, inlet temperatures, and pollutant loadings, making them suitable for diverse industrial applications. RTOs can be customized to meet specific process requirements, ensuring optimal performance and adaptability.

6. Low Maintenance Requirements: RTOs are known for their low maintenance requirements. The absence of complex moving parts and the self-sustaining nature of the system contribute to minimal maintenance needs. Routine inspections, periodic checks, and basic preventive maintenance are usually sufficient to keep the RTO operating efficiently. This reduces downtime and maintenance costs for industrial facilities.

7. Environmental Compliance: By effectively removing VOCs, HAPs, and other pollutants, RTOs enable industrial facilities to achieve and maintain compliance with environmental regulations. This ensures that the emissions from the manufacturing or process operations meet the required air quality standards, protecting the environment and surrounding communities.

The benefits of using a regenerative thermal oxidizer, including high destruction efficiency, energy efficiency, cost savings, thermal self-sustainability, flexibility, low maintenance requirements, and environmental compliance, make it a preferred choice for many industries seeking effective and sustainable air pollution control solutions.

editor by CX 2024-03-10