基本訊息

型號

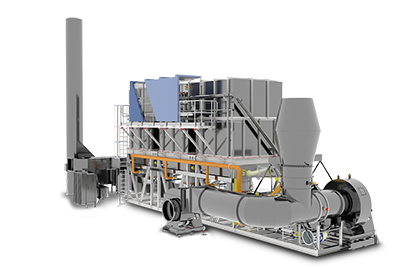

Amazing RTO

類型

Incinerator

High Efficiency

100

Energy Saving

100

Low Maintenance

100

Easy Operation

100

商標

Bjamazing

運輸套餐

Overseas

Specification

111

起源

China

HS Code

2221111

產品描述

RTO

蓄熱式熱氧化器

Compared with traditional catalytic combustion,; direct thermal oxidizer,; RTO has the merits of high heating efficiency,; low operation cost,; and the ability to treat large flux low concentration waste gas.; When VOCs concentration is high,; secondary heat recycle can be realized,; which will greatly reduce the operation cost.; Because RTO can preheat the waste gas by levels through ceramic heat accumulator,; which could make the waste gas to be completely heated and cracked with no dead corner(treatment efficiency>99%);,;which reduce the NOX in the Exhausting gas,; if the VOC density >1500mg/Nm3,; when the waste gas reach cracking area,; it has been heated up to cracking temperature by heat accumulator,; the burner will be closed under this condition.;

RTO can be devided into chamber type and rotary type according to difference operation mode.; Rotary type RTO has advantages in system pressure,; temperature stability,; investment amount,; etc

| RTO types | Efficiency | Pressure change (mmAq); | 尺寸 | (max);Treatment volume | |

| Treatment efficiency | Heat recycle efficiency | ||||

| Rotary type RTO | 99 % | 97 % | 0-4 | small (1 time); | 50000Nm3/h |

| Three chamber type RTO | 99 % | 97 % | 0-10 | Large (1.;5times); | 100000Nm3/h |

| Two chamber type RTO | 95 % | 95 % | 0-20 | middle (1.;2times); | 100000Nm3/h |

Regenerative Thermal Oxidizer,; Regenerative Thermal Oxidizer,; Regenerative Thermal Oxidizer,; Thermal Oxidizer,; Thermal Oxidizer,; Thermal Oxidizer,; oxidizer,; oxidizer,; oxidizer,; incinerator,; incinerator,; incinerator,; waste gas treatment,; waste gas treatment,; waste gas treatment,; VOC treatment,; VOC treatment,; VOC treatment,; RTO,; RTO,; RTO,; Rotary RTO,; Rotary RTO,; Rotary RTO,; Chamber RTO,; Chamber RTO,; Chamber RTO

Address: 8 floor, E1, Pinwei building, Dishengxi road, Yizhuang, ZheJiang , China

業務類型: 製造商/工廠, 貿易公司

Business Range: Electrical & Electronics, Industrial Equipment & Components, Manufacturing & Processing Machinery, Metallurgy, Mineral & Energy

Management System Certification: ISO 9001, ISO 14001

Main Products: Rto, Color Coating Line, Galvanizing Line, Air Knife, Spares for Processing Line, Coater, Independent Equipments, Sink Roll, Revamping Project, Blower

Company Introduction: ZheJiang Amazing Science & Technology Co., Ltd is a thriving Hi-tech company, located in ZheJiang Economic and Technological Development Area(BDA). Adhering to the concept of Realistic, Innovative, Focused and Efficient, our company mainly serve the waste gas treatment (VOCs) Industry and metallurgical equipment of China and even whole world. We have advanced technology and rich experience in VOCs waste gas treatment project, the reference of which has been successfully applied to the industry of coating, rubber, electronic, printing, etc. We also have years of technology accumulation in the research and manufacturing of flat steel processing line, and possess nearly 100 of application example.

Our company focus on the research, design, manufacturing, installation and commissioning of VOCs organic waste gas treatment system and the revamping and updating project for energy saving and environmental protection of flat steel processing line. We can provide customers the complete solutions for environmental protection, energy saving, product quality improvement and other aspects.

We are also engaged in various spares and independent equipment for color coating line, galvanizing line, pickling line, like roller, coupler, heat exchanger, recuperator, air knife, blower, welder, tension leveler, skin pass, expansion joint, shear, jointer, stitcher, burner, radiant tube, gear motor, reducer, etc.

Are there any incentives or grants available for installing regenerative thermal oxidizers?

Yes, there are various incentives and grants available that can help offset the cost of installing regenerative thermal oxidizers (RTOs) and other emission control technologies. These incentives are typically offered by government agencies at the local, regional, and national levels to promote environmental sustainability, air quality improvement, and compliance with emissions regulations. However, the availability and specific details of these incentives may vary depending on the location and the specific program.

Here are some examples of incentives and grants that may be available:

- Energy Efficiency Grants: Many government agencies and utility companies offer grants and financial incentives to encourage energy efficiency measures, including the installation of energy-efficient equipment like RTOs. These grants can help offset a portion of the installation costs and may be based on factors such as energy savings, reduction in greenhouse gas emissions, or specific environmental objectives.

- Environmental Grant Programs: Some governmental organizations or environmental foundations provide grants specifically targeted at reducing emissions and improving air quality. These grants may be available for industries or businesses that invest in emission control technologies, such as RTOs, to help them comply with regulations and improve their environmental performance.

- Tax Incentives and Credits: Certain jurisdictions offer tax incentives or credits to businesses or industries that invest in environmentally friendly technologies. These incentives can significantly reduce the overall cost of installing an RTO. Examples include tax credits for energy-efficient equipment, accelerated depreciation allowances, or exemptions from sales tax on eligible equipment purchases.

- Industry-Specific Programs: Some industries or sectors may have specific grant programs or incentives tailored to their unique environmental challenges. These programs may provide financial assistance for emission control projects, including the installation of RTOs, within those industries.

- Research and Development Funding: Government agencies or research organizations often provide funding opportunities for the development and implementation of innovative emission control technologies. Businesses or research institutions involved in developing advanced RTO designs or improving RTO efficiency may be eligible for research grants or funding support.

To explore the availability of incentives and grants for installing RTOs, it is recommended to contact local environmental agencies, energy efficiency programs, or business development organizations. These entities can provide information on specific incentive programs, eligibility criteria, application procedures, and any deadlines or limitations associated with the grants.

It’s important to note that incentive programs may change over time, and their availability may depend on factors such as funding allocations and government policies. Therefore, it is advisable to stay updated with the latest information and consult with relevant authorities to determine the current incentives available for installing RTOs.

Can regenerative thermal oxidizers be remotely controlled and monitored?

Yes, regenerative thermal oxidizers (RTOs) can be remotely controlled and monitored using advanced automation and control systems. Remote control and monitoring capabilities offer several benefits in terms of operational efficiency, maintenance, and troubleshooting. Here are some key points regarding the remote control and monitoring of RTOs:

- Automation Systems: RTOs can be integrated with automation systems that enable remote control and monitoring. These systems utilize programmable logic controllers (PLCs), distributed control systems (DCS), or other similar technologies to manage and optimize the operation of the RTO.

- Remote Control: With remote control capabilities, operators can adjust and modify the operating parameters of the RTO from a central control room or even remotely through secure network connections. This allows for convenient and efficient control of the RTO, making it easier to optimize performance, adjust settings, and respond to changing process conditions.

- Remote Monitoring: Remote monitoring systems enable real-time monitoring of various parameters and performance indicators of the RTO. These systems can provide insights into the operational status, temperature profiles, gas flow rates, pressure differentials, and other critical variables. Operators can access this information remotely, allowing them to assess the system’s performance, identify potential issues, and make informed decisions.

- Alarms and Notifications: Remote monitoring systems can be programmed to generate alarms and notifications based on predefined conditions or thresholds. This allows operators to receive immediate alerts in case of deviations from normal operating conditions or the occurrence of any critical events. Prompt notifications facilitate timely response and troubleshooting, minimizing downtime and potential risks.

- Data Logging and Analysis: Remote control and monitoring systems often include data logging capabilities, which capture historical data regarding the RTO’s operation and performance. This data can be analyzed to identify trends, evaluate efficiency, and optimize the system’s operation over time. It also helps in compliance reporting and maintenance planning.

- Integration with SCADA Systems: RTOs can be integrated with supervisory control and data acquisition (SCADA) systems, which provide a centralized platform for monitoring and controlling multiple processes and equipment within a facility. Integration with SCADA systems allows for a comprehensive overview of the entire operation and facilitates coordinated control and monitoring of various systems.

It is important to ensure that the remote control and monitoring systems are implemented with appropriate cybersecurity measures to protect against unauthorized access or cyber threats. Manufacturers of RTOs often provide guidance and recommendations for implementing secure remote access to their systems.

Overall, the remote control and monitoring capabilities of RTOs enhance operational efficiency, enable proactive maintenance, and facilitate faster response times, contributing to the effective and optimized operation of the air pollution control system.

What is a regenerative thermal oxidizer?

A regenerative thermal oxidizer (RTO) is an advanced air pollution control device used in industrial applications to remove volatile organic compounds (VOCs), hazardous air pollutants (HAPs), and other airborne contaminants from exhaust gases. It operates by using high temperatures to thermally decompose or oxidize the pollutants, converting them into less harmful byproducts.

蓄熱式熱氧化器如何運作?

An RTO consists of several key components and operates through a cyclical process:

1. 進氣靜壓室: 含有污染物的廢氣經由入口靜壓室進入 RTO。

2. 熱交換器床: RTO 包含多個裝有儲熱介質(通常是陶瓷材料或規則填料)的熱交換器床。熱交換器床成對佈置。

3.流量控制閥: 流量控制閥引導氣流並控制廢氣通過 RTO 的方向。

4、燃燒室: 現在引導進入燃燒室的廢氣被加熱到高溫,通常在 1400°F (760°C) 和 1600°F (870°C) 之間。此溫度範圍確保污染物的有效熱氧化。

5.VOC破壞: 燃燒室中的高溫導致揮發性有機化合物和其他污染物與氧氣反應,導致其熱分解或氧化。這個過程將污染物分解成水蒸氣、二氧化碳和其他無害氣體。

6.熱回收: 離開燃燒室的熱淨化氣體穿過出口靜壓室並流經處於相反操作階段的熱交換器床。床中的儲熱介質吸收排出氣體的熱量,從而預熱進入的廢氣。

7.循環切換: 經過特定的時間間隔後,流量控制閥會切換氣流方向,使預熱進入氣體的熱交換器床現在接收來自燃燒室的熱氣體。然後重複該循環,確保連續高效的運作。

Advantages of regenerative thermal oxidizers:

RTO 在工業空氣污染控制方面具有多種優勢:

1、效率高: RTO 可以實現很高的破壞效率,通常高於 95%,有效去除多種污染物。

2.能量回收: RTO 中的熱回收機制可以顯著節省能源。進入氣體的預熱減少了燃燒所需的燃料消耗,使 RTO 更節能。

3、性價比: 儘管 RTO 的初始資本投資可能很大,但透過能量回收和高銷毀效率節省的長期營運成本使其成為整個系統生命週期內具有成本效益的解決方案。

4. 環境合規性: RTO 旨在滿足嚴格的排放法規,並協助各行業遵守空氣品質標準和許可證。

5. 多功能性: RTO 可以處理各種製程廢氣量和污染物濃度,使其適用於各種工業應用。

Overall, regenerative thermal oxidizers are highly efficient and effective air pollution control devices widely used in industries to minimize emissions and ensure environmental compliance.

editor by CX 2024-03-08