Basic Info.

유형

Environmental Monitoring Instrument

Main Function

Waste Gases Removal

Application

Chemical Industry

Brand

Raidsant

Clean Efficeincy

99.8%

Condition

New

Trademark

Raidsant

Transport Package

Film Wrapped

Origin

ZheJiang China

Product Description

HangZhou Raidsant Machinery Co.;,; Ltd.; is majored in developing and manufacturing innovativepowder cooling pelletizing machinery and related industrial waste gas treatment machine.; With nearly 20 years’ production history,; we have a good market in more than 20 provinces in China,; and some of our products were exported to Saudi Arabia,;Singapore,;Mexico,; Brazil,;Spain,; America,; Russia and Korea,; etc.;

Specifications:;

* More compact than the existing facilities

* Low-operation costs

* Long lifespan of facilities

* No changes in pressure

Purpose:;

Energy-saving system that burns volatile organic compound (VOC); and waste gas by using heat,; and it collects over 99.;8% of waste heat of exhaust gas by using ceramic regenerative materials (catalyst); with large surface area and low-pressure loss.;

Applications:;

1.; Painting drying process

2.; metal printing process

3.; fiber drying process

4.; adhesive tape process

5.; waste treatment process

6.; semiconductor manufacturing process

7.; smoke,; confectionary and baking process

8.; petrochemical process,;

9.; medicine and food manufacturing process,;

10.; other VOC generating process

Merits:;

* More compact than the existing facilities

* No changes in pressure

* High-heat recovery rate (over 95%);

* Perfect VOC treatment (over 99.;8%);

* Long lifespan of facilities

* Low-operation costs

* Able to be manufactured in circle or quadrangle

General Descriptions and Features:;

1.; Operating principle

Operation method that continuously changing discharges by rotating the Rotary Valve

2.; Process Pressure Change

No pressure change because wind direction changes in order by the Rotary Valve rotation

3.; Investment Costs

Around 70% of Bed Type

4.; Installation Space

It is single vessel so it is compact and requires less installation space.;

5.; Maintenance

It is easy to maintain it because Rotary Valve is the only 1 moving part.;

Rotary Valve’s sealing part is rarely worn out because it rotates at low speed.;

6.; Stability

No risks in the process because it is always opened even when the Rotary Valve has troubles.;

7.; Treatment Efficiency

Treatment efficiency maintains because sealing part is rarely worn out even if it is operated for a long time.;

Address: No.3,Zhenxin Middle Road, Economic Development Zone,HangZhou,ZheJiang

Business Type: Manufacturer/Factory, Trading Company

Business Range: Chemicals, Electrical & Electronics, Manufacturing & Processing Machinery, Security & Protection

Management System Certification: ISO 9001

Main Products: Pelletizer, Flaker, Pastillator, Granulator, Chemical Pelletizer, Vocs

Company Introduction: HangZhou Raidsant Machinery Co., Ltd. ., previously called HangZhou Xinte Plastic Machinery Factory is majored in producing innovative plastic recycling machinery. With nearly 20 years′ experience, we have a good market in 20 provinces in China, and some of our products were exported to Indonesia, Russia and Vietnam, etc. Our main products include DZ Type Pastillator, waste tire recycling line, Big Calibre Plastic Pipe shredders recycling line, continuous annealing tin-coation machine, QX type PET, PE & hull washing line, SDP double rails plastic recycling crusher, SJ hot cutting granule making unit, PVC tube (cinquefoil) product line, PVC Odd-shaped material product line for door and window, granule product line in water and Shredder for plastics and recycling. We acquired 5 technical patents.

Our corpotation lays emphsis on thchnical reconstruction, imports advanced technology from home and abroad, and develops new products constantly. Our tenet is challenging for hight quality, offering the best products. We are making efforts to realize our slogan. Satisfying our customers is our everlasting pursuit.

We are looking for the oversea customers or agents. If you are interested in our proposal, please let us know which of our products is the most likely to appeal to you or your customers. We should be very grateful if you give us some ideas of the marketprospects for our products. We hope to hear favorable information from you soon! It is our goal that we wish we could buid a good relationship with you now or in the near future. Please do not hesitate to contact us if you have any question or request.

We also sincerely welcome you to our company to discuss business and negotiate with us. For further expanding our market and customers, our company welcomes customer from domestic and aboard in an new-brand gesture on the basis of full-new mangement conception—quality, honour, service. We are looking for ISO 90001 mangement quality system to meet with our customers requirement!

How do regenerative thermal oxidizers comply with emissions regulations?

Regenerative thermal oxidizers (RTOs) are designed to help industries comply with emissions regulations and air quality standards. They employ several mechanisms to ensure compliance:

- Pollutant Destruction Efficiency: RTOs are engineered to achieve high destruction efficiencies for pollutants, typically exceeding 99%. This means that the vast majority of volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) present in industrial exhaust streams are effectively destroyed, reducing their emissions to levels that meet or exceed regulatory requirements.

- Emission Monitoring and Reporting: RTOs often incorporate monitoring systems to measure and record various parameters, including pollutant concentrations, temperature, airflow rates, and pressure differentials. These systems enable operators to continuously monitor the performance of the RTO and ensure compliance with emissions regulations. The collected data can be used for reporting purposes to demonstrate compliance to regulatory authorities.

- Compliance with Emission Limits: RTOs are designed and operated to meet specific emission limits set by local, regional, and national regulatory agencies. These emission limits define the maximum allowable concentrations or mass emissions of pollutants that can be released into the atmosphere. RTOs are equipped with control mechanisms, such as combustion chambers, heat recovery systems, and monitoring devices, to achieve and maintain emission levels within the prescribed limits.

- Regulatory Standards and Certifications: RTOs are designed and manufactured in accordance with industry standards and guidelines, such as those set by environmental protection agencies and organizations. Compliance with these standards ensures that the RTOs meet specific criteria for performance, safety, and emissions control. Additionally, some RTO manufacturers may obtain certifications or approvals from regulatory bodies to validate their equipment’s compliance with emissions regulations.

- Periodic Inspections and Maintenance: Regular inspections, maintenance, and performance evaluations are essential to ensure ongoing compliance with emissions regulations. These activities help identify any potential issues or deviations from the required performance levels and allow for timely corrective actions. Proper maintenance practices, such as cleaning of heat exchangers, replacement of damaged components, and calibration of monitoring devices, contribute to maintaining the RTO’s effectiveness in emissions control.

It’s important to note that compliance with emissions regulations is a shared responsibility between the industry operating the RTO and the regulatory authorities overseeing environmental compliance. Industries must follow proper operating procedures, adhere to emission limits, and maintain the RTO in accordance with manufacturer’s guidelines and regulatory requirements to ensure continuous compliance.

How do regenerative thermal oxidizers handle variations in pollutant composition?

Regenerative thermal oxidizers (RTOs) are designed to handle variations in pollutant composition effectively. RTOs are commonly used for treating volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) emitted from various industrial processes. Here are some key points regarding how RTOs handle variations in pollutant composition:

- Thermal Oxidation Process: RTOs utilize a thermal oxidation process to eliminate pollutants. The process involves raising the temperature of the exhaust gas to a level where the pollutants react with oxygen and are oxidized to carbon dioxide (CO2) and water vapor. This high-temperature oxidation process is effective in treating a wide range of pollutants, regardless of their specific composition.

- Wide Range of Pollutant Compatibility: RTOs are designed to handle a broad spectrum of pollutants, including VOCs and HAPs with varying chemical compositions. The high operating temperatures in the RTO, typically between 1400°F to 1600°F (760°C to 870°C), ensure that a wide range of organic compounds can be effectively oxidized, regardless of their molecular structure or chemical makeup.

- Residence Time and Dwell Time: RTOs provide sufficient residence time and dwell time for the exhaust gas within the oxidizer. The exhaust gas is directed through a heat exchange system, where it passes through ceramic media beds or heat exchange media. These media beds absorb the heat from the high-temperature combustion chamber and transfer it to the incoming exhaust gas. The extended residence time and dwell time ensure that even complex or less reactive pollutants have enough contact time with the elevated temperature to be effectively oxidized.

- Heat Recovery: RTOs incorporate heat recovery systems that maximize thermal efficiency. The heat exchangers within the RTO capture and transfer heat from the outgoing exhaust gas to the incoming process stream. This heat exchange process helps maintain the high operating temperatures required for effective pollutant destruction while minimizing the energy consumption of the system. The ability to recover and reuse heat also contributes to the RTO’s ability to handle variations in pollutant composition.

- Advanced Control Systems: RTOs employ advanced control systems to monitor and optimize the oxidation process. These control systems continuously monitor parameters such as temperature, flow rates, and pollutant concentrations. By adjusting the operating conditions in response to variations in pollutant composition, the control systems ensure optimal performance and maintain high destruction efficiencies.

In summary, RTOs handle variations in pollutant composition by utilizing a thermal oxidation process, accommodating a wide range of pollutants, providing sufficient residence time and dwell time, incorporating heat recovery systems, and employing advanced control systems. These features allow RTOs to effectively treat emissions with different pollutant compositions, ensuring high destruction efficiencies and compliance with environmental regulations.

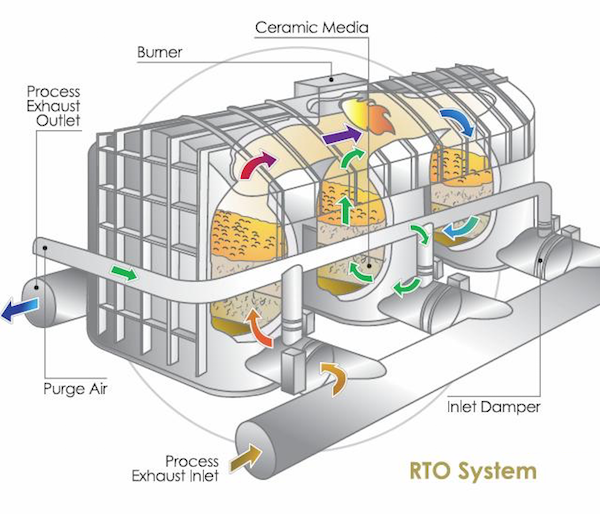

How does a regenerative thermal oxidizer work?

A regenerative thermal oxidizer (RTO) is an advanced air pollution control device that operates through a cyclical process to remove volatile organic compounds (VOCs), hazardous air pollutants (HAPs), and other airborne contaminants from exhaust gases. Here’s a detailed explanation of how an RTO works:

1. Inlet Plenum: The exhaust gases containing pollutants enter the RTO through the inlet plenum.

2. Heat Exchanger Beds: The RTO contains multiple heat exchanger beds filled with heat storage media, typically ceramic materials or structured packing. The heat exchanger beds are arranged in pairs.

3. Flow Control Valves: Flow control valves direct the airflow and control the direction of the exhaust gases through the RTO.

4. Combustion Chamber: The exhaust gases, now directed into the combustion chamber, are heated to a high temperature, typically between 1400°F (760°C) and 1600°F (870°C). This temperature range ensures effective thermal oxidation of the pollutants.

5. VOC Destruction: The high temperature in the combustion chamber causes the VOCs and other contaminants to react with oxygen, resulting in their thermal decomposition or oxidation. This process breaks down the pollutants into water vapor, carbon dioxide, and other harmless gases.

6. Heat Recovery: The hot, purified gases leaving the combustion chamber pass through the outlet plenum and flow through the heat exchanger beds that are in the opposite phase of operation. The heat storage media in the beds absorb heat from the outgoing gases, which preheats the incoming exhaust gases.

7. Cycle Switching: After a specific time interval, the flow control valves switch the airflow direction, allowing the heat exchanger beds that were preheating the incoming gases to now receive the hot gases from the combustion chamber. The cycle then repeats, ensuring continuous and efficient operation.

Advantages of a regenerative thermal oxidizer:

RTOs offer several advantages in industrial air pollution control:

1. High Efficiency: RTOs can achieve high destruction efficiencies, typically above 95%, effectively removing a wide range of pollutants.

2. Energy Recovery: The heat recovery mechanism in RTOs allows for significant energy savings. The preheating of incoming gases reduces the fuel consumption required for combustion, making RTOs energy-efficient.

3. Cost-effectiveness: Although the initial capital investment for an RTO can be significant, the long-term operational cost savings through energy recovery and high destruction efficiencies make it a cost-effective solution over the lifespan of the system.

4. Environmental Compliance: RTOs are designed to meet stringent emissions regulations and help industries comply with air quality standards and permits.

5. Versatility: RTOs can handle a wide range of process exhaust volumes and pollutant concentrations, making them suitable for various industrial applications.

Overall, a regenerative thermal oxidizer operates by utilizing heat recovery, high-temperature combustion, and cyclical flow control to effectively oxidize pollutants and achieve high destruction efficiencies while minimizing energy consumption.

editor by CX 2024-03-14