Projektový případ

Regenerační tepelný oxidátor Cases

RTO for Whole plant solution

Konfigurace zařízení:

- 3x40000 Nm³/h-RTO

- 1000000 Nm³/h-zeolitový rotor

- 3x6t/h-2,0MPa Parní kotel

RTO for High concentration waste gas solution

Konfigurace zařízení:

- 30 000 Nm³/h-RTO

- 6t/h-teplovodný olejový kotel

| Projekt | Index |

| Koncentrace | 8600 mg/m³ |

| Objem | 30 000 Nm³/h |

| Složení | Ethylester, toluen |

| Očista účinnost | 99.62% |

| Emisní limit | 28.8mg/m³ |

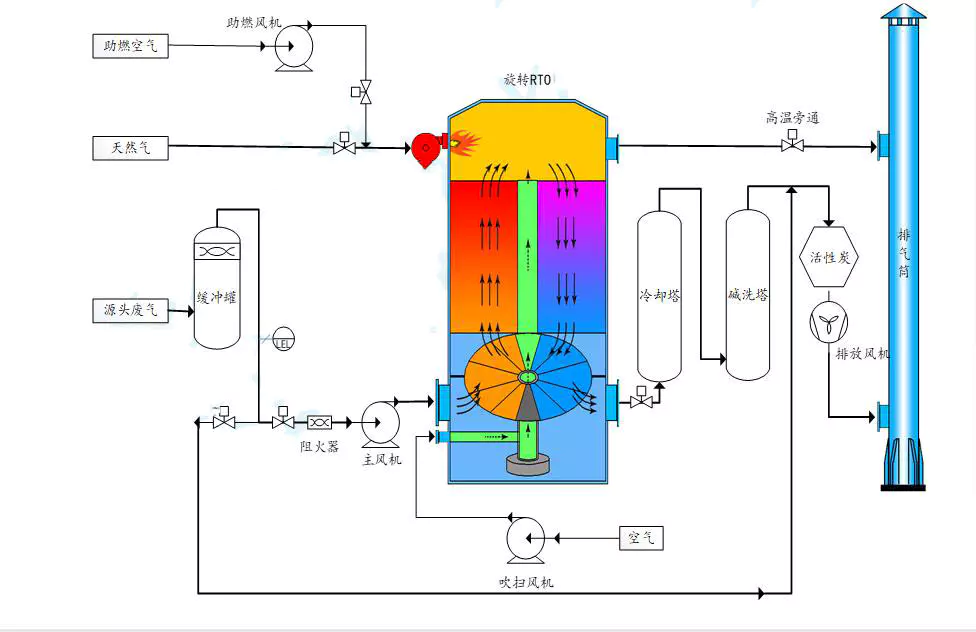

Low concentration solution

Konfigurace zařízení:

- 10000Nm³/h-RTO

- 80000Nm³/h-Zeolite rotor

| Projekt | Index |

| Koncentrace | 620mg/m³ |

| Objem | 80000Nm³/h |

| Složení | Xylene, butyl |

| Očista účinnost | 96.1 % |

| Emisní limit | 24.18mg/m³ |

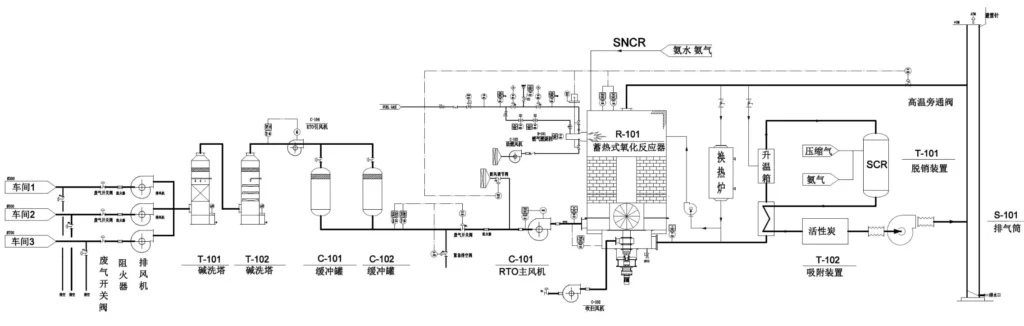

Solutions for complex chemical waste gas

Organic waste gas: Alkanes, olefins, alkynes, aromatic aldehydes, ketones, ethers, sulfur/chlorine/nitrogen organics

Accompanying components: H2S, SO2HCl CO, NH3

| Difficulty | Measures | Difficulty | Measures |

| Corrosive gas | Alkaline washing, pickling, dehumidification, Corrosion resistant material, Anticorrosive coating | NOx | SNCR/SCR Denitration |

| Concentration surge | Buffer tank, FTA concentration peak remote warning | Viscous polymer | Plate type heat storage ceramic and 12 manholes for maintenance |

| dioxin | activated carbon adsorption | waste heat | Hot air recovery |

Waste gas solution of the sewage tank

Waste gas components:

- Ammonia, hydrogen chloride, xylene Ammonia content 20%

- The lower explosion limit Process composite of ammonia is 15%

Process composition:

- Spray tower +RTO+SCR

- 10000Nm³/h RTO

- 50000Nm³/h RTO

Features:

- Chlorine and corrosion-resistant materials

- NOx emission control

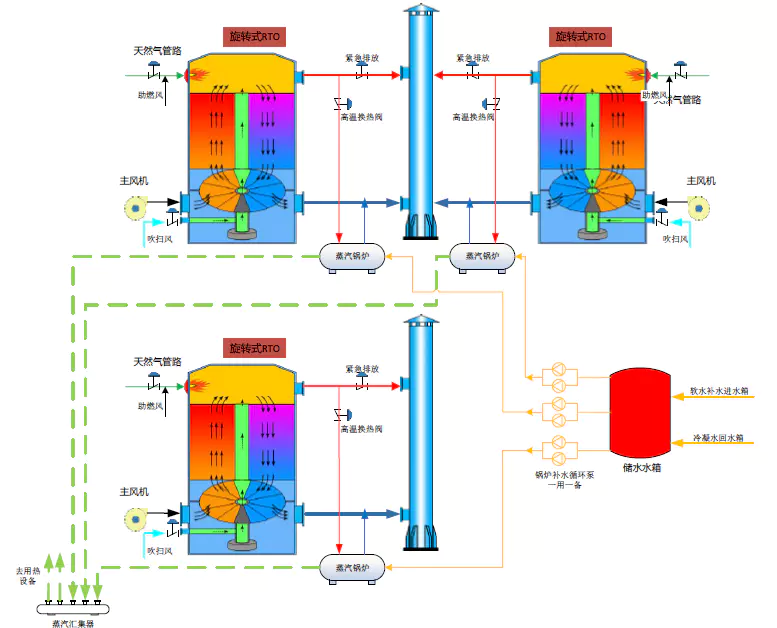

Thermal energy utilization solutions

Konfigurace zařízení:

- 3x40000 Nm³/h-RTO

- 3x8t/h-2.0MPa boiler

- 3000KW Steam type lithium

- bromide refrigerator

Concentration surge solutions

Features:

Concentration surge, chlorine-containing

corrosion, amine-containing

Waste gas components:

3-methylpyridine, 3-cyanopyridine, 3-aminopyridine, methanol, toluene, ethanol, triethylamine, chloroform, short chain fatty acids, aliphatic hydrocarbons, ammonia and trichloroethylene

Process composition:

Concentration fluctuation pretreatment + RTO corrosion prevention + post-treatment to remove hydrogen chloride and dioxin

Konfigurace zařízení:

- 2x40000Nm³/h-RTO

Waste gas pipeline

Pretreatment system

Asphalt fume solution

Features:

High boiling point lipid aerosol, Dust

Process composition:

- Pipe heat tracing

- Oil drain

- Fire fighting system

- Cyclone filter

- Screen filter

- Quick replacement of Bottom heat storage ceramic

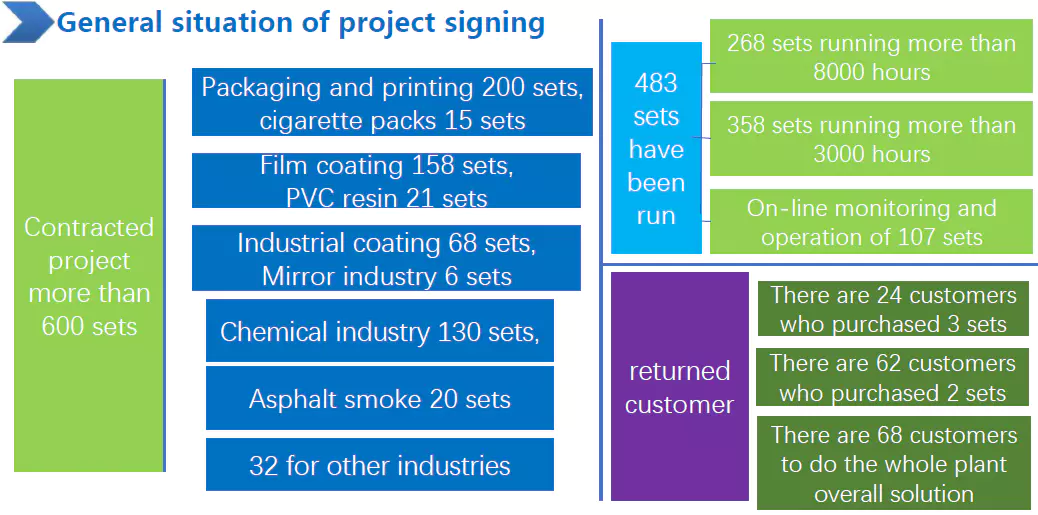

Marketing a aplikace regenerativního tepelného oxidátoru

Obecná situace podpisu projektu

Contact us now to get your own project with regenerační tepelná oxidační činidla that we have for sale!