Základní informace.

Material

Cordierite

Aplikace

Industry, Food and Beverage, Medicine, Textile, Metallurgy

Typ

Ceramic Filter

Filter Connector

Flat Connector

Filtration Grade

ULPA Filter

Activated Carbon Filter Type

Bulk Type

Ochranná známka

SW

Přepravní balíček

Carton

Specifikace

50x50x50, 100x100x50, 595x260x95

Původ

Čína

Kód HS

3815120090

Popis produktu

Description:;

Carrier:; Ceramic honeycomb substrate (cordierite monolith); or metal honeycomb substrate (stainless steel crust and Fe-Cr-Al honeycomb body);.;

Technical Data:;

Material:;Cordierite,; mullite ceramics

Size:;

50x50x50,;100x100x50,;595x260x95

Working Temperature:;220°C-1100°C

Channels:;Circular,; Square,; Rectangle

Cell Density:;

50-400 CPSI

Type:; Catalytic Converter

Usage:;

Catalytic Converter

Application:;Enameled wire,; paint room,; waste gas treatment industry.;

——————————————————————————————————————————————————

Regenerative Thermal/Catalytic Oxidizer (RTO/RCO); :;

Regenerated heat/catalytic oxidant (RTO/RCO);:; it is widely used in automotive coatings,; chemical industry,; electronic and electric manufacturing industry,; contact combustion system and other fields.;Ceramic honeycomb is designated as a structural regenerative medium for RTO/RCO.;

Advantage:;

1.; Various materials and specifications

2.; Products with different formulas can be customized according to customer requirements.;

3.; Small resistance loss

4.; Low thermal expansion coefficient

5.; Excellent crack resistance

6.; It can be customized to meet the emission standards of different countries.;

Aplikace:;

1.; It can be used as a heat exchanger in the RTO of the heat recovery device.;

2.; Can be used as a catalyst to purify automobile exhaust and motorcycle exhaust to remove odor.;

3.; Applicable to food service industry,; environmental protection industry,; metallurgy industry,; etc

Test Equipment:;

Particle size distribution tester

Aperture and specific surface meter

Metal distribution,; crystalline structure

Catalyst activity evaluation system

Production Equipment:;

Coating continuous microwave drying system

Slurry nanometer grinding preparation system

Slurry quantitative spraying system

RFQ:;

Q:;Are you a trading company or a manufacturer?

A:;We are professional manufacturer which has almost 20 years of experience in this industry.;

Q:;Can you produce according to the samples?

A:;Yes,;we can produce by your samples or technical drawings.;

Q:;Would it be possible for us to visit your factory?

A:;Sure,;we welcomed our customers visit our factory in any time.;

Q:;Will your company supply samples?

A:;Yes,;the sample expense will be deducted from the value of your order.;

Q:;What’s your payment terms?

A:;T/T,; L/C,; Western Union,; Money Gram,; are available for us.;

Q:;Delivery time for my order?

A:;Within 7-15 working days for your sample order; 20 working days for your bulk order( It depends on the models and quantity you are going to order);.;

Address: Room. 3902-2 TianAn CHINAMFG Town No. 228 Ling Lake Avenue, New Wu District, HangZhou City, ZheJiang Province, China.

Business Type: Manufacturer/Factory, Group Corporation

Business Range: Auto, Motorcycle Parts & Accessories, Chemicals, Industrial Equipment & Components, Manufacturing & Processing Machinery

Management System Certification: ISO 9001, ISO 14001, ISO 20000, IATF16949

Main Products: Honeycomb Catalytic, Three Way Catalytic, Chemical Catalytic, Exhaust Filter, Industrial Catalytic

Company Introduction: Established in 2003, Sheung Well International Corp. Is a professional enterprise specialized in developing, manufacturing, selling automotive vehicles, Universal fuel engine and industrial three-way catalyst and converters, four-way converters. With independent intellectual property rights, its technology has been approved by ISO9001, TS16949 quality and management systems.

Sheung Well is an all-round designer and manufacturer who has a innovative and quality managing team mainly consists of doctorates and masters. Based on its cutting edge technology, rich experience and modern production and quality management skills, CHINAMFG is providing customers with first-class products and services.

Oriented in market, with innovation as its soul, centralized in serving the society, CHINAMFG lays emphasis on developing technology and products of controlling Exhaust emissions and other industrial catalysts. By providing customers with technology and supports of new products, it is committed to becoming the word-class all-around enterprise in catalyst circle from home and abroad.

Jaké jsou regenerační tepelné oxidační prostředky ve srovnání s katalytickými oxidačními prostředky?

Regenerativní tepelné oxidační prostředky (RTO) a katalytické oxidační prostředky jsou účinné technologie používané pro kontrolu emisí do ovzduší z průmyslových procesů. I když slouží podobnému účelu, existují významné rozdíly v jejich provozu, účinnosti a použitelnosti.

Zde je srovnání mezi RTO a katalytickými oxidačními činidly:

| Regenerační tepelné oxidátory (RTO) | Katalytické oxidátory |

|---|---|

| Operace: | Operace: |

| RTO dosahují kontroly emisí prostřednictvím vysokoteplotního spalování bez použití katalyzátoru. Spoléhají na proces tepelné oxidace, kde se VOC a další znečišťující látky ve výfukových plynech oxidují při vysokých teplotách (typicky mezi 1400 °F a 1600 °F) v přítomnosti přebytku kyslíku. | Katalytické oxidační prostředky využívají katalyzátor (obvykle drahý kov, jako je platina, palladium nebo rhodium) k usnadnění oxidace VOC a dalších znečišťujících látek při nižších teplotách ve srovnání s RTO. Katalyzátor snižuje aktivační energii potřebnou pro oxidační reakci, což umožňuje její průběh při nižších teplotách (kolem 600 °F až 900 °F). |

| Účinnost: | Účinnost: |

| RTO jsou známé svou vysokou tepelnou účinností. Využívají systém regenerativního výměníku tepla, který rekuperuje a přenáší teplo z upravených výfukových plynů do přicházejících neupravených plynů, což výrazně snižuje spotřebu paliva. Tento mechanismus rekuperace tepla činí RTO energeticky účinnými. | Katalytické oxidátory jsou obecně energeticky účinnější než RTO, protože pracují při nižších teplotách. Katalyzátor usnadňuje oxidační reakci, umožňuje její průběh při nižších teplotách, což snižuje spotřebu energie na ohřev výfukových plynů. |

| Použitelnost: | Použitelnost: |

| RTO jsou zvláště vhodné pro aplikace, kde jsou koncentrace znečišťujících látek vysoké nebo kde existují velké rozdíly v průtokech nebo koncentracích znečišťujících látek. Běžně se používají pro kontrolu těkavých organických sloučenin (VOC) a nebezpečných látek znečišťujících ovzduší (HAP) v různých průmyslových odvětvích, včetně chemické výroby, tisku, nátěrů a farmaceutických výrobků. | Katalytická oxidační činidla jsou často preferována v aplikacích, kde jsou koncentrace znečišťujících látek relativně nízké a relativně konstantní. Jsou účinné pro kontrolu VOC v aplikacích, jako je lakování automobilů, tisk a zpracování potravin, kde mohou být koncentrace VOC nižší a konzistentnější. |

| Omezení: | Omezení: |

| RTO mají vyšší kapitálové náklady ve srovnání s katalytickými oxidačními zařízeními kvůli jejich složité konstrukci a systému rekuperace tepla. Mají také vyšší provozní teplotu, což může omezit jejich použitelnost v určitých procesech nebo vyžadovat další systémy rekuperace tepla. | Katalytická oxidační činidla mohou být citlivá na jedy nebo nečistoty ve výfukových plynech, které mohou časem deaktivovat nebo degradovat katalyzátor. Některé sloučeniny, jako je síra, silikony nebo halogenované sloučeniny, mohou potenciálně otrávit katalyzátor, snížit jeho účinnost a vyžadovat periodickou výměnu katalyzátoru nebo jeho regeneraci. |

Při výběru mezi RTO a katalytickým oxidátorem je nezbytné vzít v úvahu specifické požadavky aplikace, včetně koncentrací znečišťujících látek, průtoků, požadavků na teplotu a nákladů. Konzultace s odborníky v oblasti environmentálního inženýrství nebo výrobci zařízení mohou pomoci určit nejvhodnější technologii pro konkrétní potřebu kontroly emisí.

How do regenerative thermal oxidizers compare to biofilters in terms of performance?

Regenerative thermal oxidizers (RTOs) and biofilters are both widely used technologies for the treatment of air pollutants, but they differ in their operating principles and performance characteristics. Here’s a comparison of RTOs and biofilters in terms of their performance:

| Performance Aspect | Regenerační tepelné oxidátory (RTO) | Biofilters |

|---|---|---|

| Emission Removal Efficiency | RTOs are highly efficient in removing volatile organic compounds (VOCs) and hazardous air pollutants (HAPs). They can achieve destruction efficiencies above 95% for these pollutants. | Biofilters also have the potential to achieve high removal efficiencies for certain VOCs and odorous compounds. However, their performance can vary depending on the specific contaminants and the microbial activity in the biofilter. |

| Applicability | RTOs are versatile and can handle a wide range of pollutants, including VOCs, HAPs, and odorous compounds. They are well-suited for high flow rates and high pollutant concentrations. | Biofilters are particularly effective in treating odorous compounds and certain VOCs. They are commonly used in applications such as wastewater treatment facilities, composting operations, and agricultural facilities. |

| Energy Consumption | RTOs require a significant amount of energy to reach and maintain high operating temperatures for oxidation. They rely on fuel combustion or external heat sources for the thermal energy needed. | Biofilters are considered low energy consumption systems as they rely on the natural biological activity of microorganisms to break down pollutants. They generally do not require external heating or fuel consumption. |

| Maintenance | RTOs typically require regular maintenance and monitoring to ensure proper operation. This includes inspections, cleaning of heat exchange media, and potential repairs or replacements of components. | Biofilters require periodic maintenance to optimize their performance. This may involve monitoring and adjusting moisture levels, controlling temperature, and occasionally replacing the filter media or adding microbial inoculants. |

| Capital and Operating Costs | RTOs generally have higher capital costs compared to biofilters due to their complex design, specialized materials, and energy-intensive operation. Operating costs include fuel consumption or electricity for heating. | Biofilters generally have lower capital costs compared to RTOs. They are simpler in design and do not require fuel consumption. However, operating costs may include periodic replacement of filter media and potential odor control measures. |

It is important to note that the selection of the appropriate technology depends on various factors such as the specific pollutants to be treated, process conditions, regulatory requirements, and site-specific considerations. Consulting with environmental engineers or air pollution control experts can help determine the most suitable technology for a particular application.

In summary, RTOs and biofilters offer different performance characteristics, with RTOs excelling in high removal efficiencies, versatility, and suitability for high-flow and high-concentration applications, while biofilters are effective for odorous compounds, have low energy consumption, and generally lower capital costs.

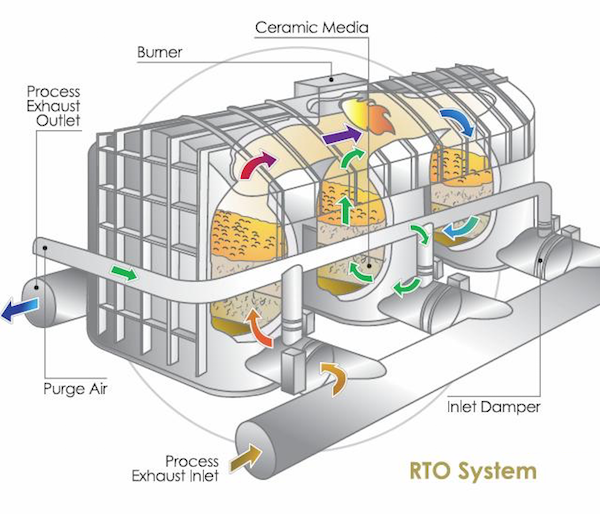

What are the key components of a regenerative thermal oxidizer?

A regenerative thermal oxidizer (RTO) typically consists of several key components that work together to achieve effective air pollution control. The main components of an RTO include:

- 1. Combustion Chamber: The combustion chamber is where the oxidation of the pollutants takes place. It is designed to withstand high temperatures and house the ceramic media beds that facilitate heat exchange and VOC destruction. The combustion chamber provides a controlled environment for the combustion process to occur efficiently.

- 2. Ceramic Media Beds: Ceramic media beds are the heart of an RTO. They are filled with structured ceramic materials that act as a heat sink. The media beds alternate between the inlet and outlet sides of the RTO, allowing for efficient heat transfer. As the VOC-laden air passes through the media beds, it is heated by the stored heat from the previous cycle, promoting combustion and VOC destruction.

- 3. Valves or Dampers: Valves or dampers are used to direct the airflow within the RTO. They control the flow of the process air and the direction of the exhaust gases during the different phases of operation, such as the heating, combustion, and cooling cycles. Proper valve sequencing ensures optimal heat recovery and VOC destruction efficiency.

- 4. Burner System: The burner system provides the necessary heat to raise the temperature of the incoming process air to the required combustion temperature. It typically uses natural gas or another fuel source to generate the heat energy needed for the destruction of VOCs. The burner system is designed to provide stable and controlled combustion conditions within the RTO.

- 5. Heat Recovery System: The heat recovery system enables energy efficiency in an RTO. It captures and preheats the incoming process air by utilizing the heat energy from the outgoing exhaust stream. The heat exchange occurs between the ceramic media beds, allowing for significant energy savings and reducing the overall operating costs of the RTO.

- 6. Control System: The control system of an RTO monitors and regulates the operation of various components. It ensures proper valve sequencing, temperature control, and safety interlocks. The control system optimizes the performance of the RTO, maintains the desired destruction efficiency, and provides necessary alarms and diagnostics for efficient operation and maintenance.

- 7. Stack or Exhaust System: The stack or exhaust system is responsible for releasing the treated and cleaned gases into the atmosphere. It may include a stack, ductwork, and any necessary emission monitoring equipment to ensure compliance with environmental regulations.

These key components work together in a coordinated manner to provide efficient air pollution control in a regenerative thermal oxidizer. Each component plays a critical role in achieving high VOC destruction efficiency, energy recovery, and compliance with environmental standards.

editor by CX 2024-03-04