Основна информация.

Модел NO.

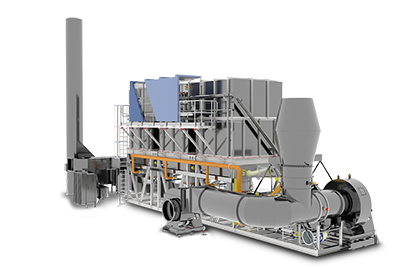

Невероятен RTO

Тип

Инсинератор

Висока ефективност

100

Less Maintenance

100

Easy for Operation

100

Икономия на енергия

100

Търговска марка

Бямазинг

Транспортен пакет

Overseas Wooden

Спецификация

180*24

Произход

Китай

Код по ХС

8416100000

Описание на продукта

RTO

Регенеративен термичен окислител

Compared with traditional catalytic combustion, direct thermal oxidizer, RTO has the merits of high heating efficiency, low operation cost, and the ability to treat large flux low concentration waste gas. When VOCs concentration is high, secondary heat recycle can be realized, which will greatly reduce the operation cost. Because RTO can preheat the waste gas by levels through ceramic heat accumulator, which could make the waste gas to be completely heated and cracked with no dead corner(treatment efficiency>99%),which reduce the NOX in the Exhausting gas, if the VOC density >1500mg/Nm3, when the waste gas reach cracking area, it has been heated up to cracking temperature by heat accumulator, the burner will be closed under this condition.

RTO can be devided into chamber type and rotary type according to difference operation mode. Rotary type RTO has advantages in system pressure, temperature stability, investment amount, etc

| RTO видове | Ефективност | Промяна на налягането (mmAq) | Размер | (max)Treatment volume | |

| Ефективност на лечението | Ефективност на рециклиране на топлина | ||||

| Ротационен тип RTO | 99 % | 97 % | 0-4 | small(1 time) | 50000Nm3/h |

| Трикамерен тип RTO | 99 % | 97 % | 0-10 | Голям (1.5times) | 100000Nm3/h |

| Двукамерен тип RTO | 95 % | 95 % | 0-20 | middle(1.2times) | 100000Nm3/h |

Regenerative Thermal Oxidizer, Regenerative Thermal Oxidizer, Regenerative Thermal Oxidizer, Thermal Oxidizer, Thermal Oxidizer, Thermal Oxidizer, oxidizer, oxidizer, oxidizer, incinerator, incinerator, incinerator, waste gas treatment, waste gas treatment, waste gas treatment, VOC treatment, VOC treatment, VOC treatment, RTO, RTO, RTO, RTO, RTO, RTO

Адрес: 8 етаж, E1, сграда Pinwei, път Dishengxi, Yizhuang, ZheJiang, Китай

Тип бизнес: производител/фабрика, търговска компания

Бизнес диапазон: Електротехника и електроника, Индустриално оборудване и компоненти, Машини за производство и обработка, Металургия, Минерали и енергия

Сертифициране на системата за управление: ISO 9001, ISO 14001

Основни продукти: Rto, линия за цветно покритие, линия за поцинковане, въздушен нож, резервни части за производствена линия, машина за нанасяне на покритие, независимо оборудване, ролка за мивки, проект за обновяване, вентилатор

Представяне на компанията: ZheJiang Amazing Science & Technology Co., Ltd е процъфтяваща високотехнологична компания, разположена в зоната за икономическо и технологично развитие на ZheJiang (BDA). Придържайки се към концепцията за реалистични, иновативни, фокусирани и ефективни, нашата компания обслужва главно обработката на отпадъчни газове (ЛОС) промишлеността и металургичното оборудване на Китай и дори на целия свят. Разполагаме с напреднали технологии и богат опит в проекта за третиране на отпадъчни газове с летливи органични съединения, чието позоваване е успешно приложено в индустрията за покрития, каучук, електроника, печат и т.н. Също така имаме години натрупване на технологии в изследването и производството на плоски линия за обработка на стомана и притежава близо 100 примера за приложение.

Нашата компания се фокусира върху проучването, проектирането, производството, инсталирането и пускането в експлоатация на система за третиране на органични отпадъчни газове с ЛОС и проект за обновяване и актуализиране на енергоспестяване и опазване на околната среда на линия за обработка на плоска стомана. Ние можем да предоставим на клиентите цялостни решения за опазване на околната среда, енергоспестяване, подобряване на качеството на продуктите и други аспекти.

Ние също така се занимаваме с различни резервни части и независимо оборудване за линия за цветно покритие, линия за поцинковане, линия за ецване, като валяк, съединител, топлообменник, рекуператор, въздушен нож, вентилатор, заварчик, изравнител на опън, кожен проход, разширителна фуга, срязване, фуги , шевна машина, горелка, лъчиста тръба, редуктор, редуктор и др.

Can regenerative thermal oxidizers be used for abating hazardous air pollutants (HAPs)?

Yes, regenerative thermal oxidizers (RTOs) can be used effectively for abating hazardous air pollutants (HAPs). RTOs are widely recognized and employed as one of the most efficient and reliable technologies for the destruction of a wide range of volatile organic compounds (VOCs) and hazardous air pollutants.

Here are some key points regarding the use of RTOs for abating HAPs:

- High Destruction Efficiency: RTOs are known for their high destruction efficiency, which refers to their ability to effectively oxidize and destroy HAPs. The combustion chamber within the RTO is designed to maintain a sufficiently high temperature (typically above 1,400°F or 760°C) to ensure complete oxidation of the pollutants, including HAPs.

- Wide Applicability: RTOs can handle a wide range of HAPs and VOCs, including but not limited to benzene, toluene, xylene, chlorinated compounds, formaldehyde, and various other organic pollutants. Their versatility makes them suitable for diverse industrial applications where HAPs may be present.

- Retention Time: RTOs are designed with a sufficient residence or retention time within the combustion chamber. This allows the exhaust gases containing HAPs to spend enough time in the high-temperature zone, ensuring that HAPs are adequately treated and oxidized to harmless byproducts.

- Възстановяване на топлина: The heat recovery system in an RTO, typically using ceramic media beds or heat exchangers, plays a crucial role in the destruction of HAPs. The heat recovery system helps maintain the required temperature and provides thermal energy to sustain the combustion process, ensuring effective destruction of HAPs even during variable operating conditions.

- Съответствие с разпоредбите: RTOs are designed to meet stringent environmental regulations governing HAP emissions. By effectively destroying HAPs, RTOs help industries comply with air quality standards and emission limits set by regulatory agencies.

- Monitoring and Controls: RTOs are equipped with advanced monitoring and control systems that continuously monitor parameters such as temperature, pressure, and pollutant concentrations. These systems ensure the optimal performance of the RTO in treating HAPs and allow for adjustments and optimization as needed.

It’s important to note that the specific design and configuration of an RTO may need to be tailored to the characteristics of the HAPs being treated. Factors such as the HAPs’ chemical composition, concentration, and other process-specific considerations may influence the selection and customization of the RTO system.

In summary, RTOs are highly effective and reliable technologies for abating hazardous air pollutants. Their high destruction efficiency, wide applicability, and compliance with regulations make them a preferred choice for industries seeking to mitigate the environmental impact of HAP emissions.

Can regenerative thermal oxidizers be remotely controlled and monitored?

Yes, regenerative thermal oxidizers (RTOs) can be remotely controlled and monitored using advanced automation and control systems. Remote control and monitoring capabilities offer several benefits in terms of operational efficiency, maintenance, and troubleshooting. Here are some key points regarding the remote control and monitoring of RTOs:

- Automation Systems: RTOs can be integrated with automation systems that enable remote control and monitoring. These systems utilize programmable logic controllers (PLCs), distributed control systems (DCS), or other similar technologies to manage and optimize the operation of the RTO.

- Remote Control: With remote control capabilities, operators can adjust and modify the operating parameters of the RTO from a central control room or even remotely through secure network connections. This allows for convenient and efficient control of the RTO, making it easier to optimize performance, adjust settings, and respond to changing process conditions.

- Remote Monitoring: Remote monitoring systems enable real-time monitoring of various parameters and performance indicators of the RTO. These systems can provide insights into the operational status, temperature profiles, gas flow rates, pressure differentials, and other critical variables. Operators can access this information remotely, allowing them to assess the system’s performance, identify potential issues, and make informed decisions.

- Alarms and Notifications: Remote monitoring systems can be programmed to generate alarms and notifications based on predefined conditions or thresholds. This allows operators to receive immediate alerts in case of deviations from normal operating conditions or the occurrence of any critical events. Prompt notifications facilitate timely response and troubleshooting, minimizing downtime and potential risks.

- Data Logging and Analysis: Remote control and monitoring systems often include data logging capabilities, which capture historical data regarding the RTO’s operation and performance. This data can be analyzed to identify trends, evaluate efficiency, and optimize the system’s operation over time. It also helps in compliance reporting and maintenance planning.

- Integration with SCADA Systems: RTOs can be integrated with supervisory control and data acquisition (SCADA) systems, which provide a centralized platform for monitoring and controlling multiple processes and equipment within a facility. Integration with SCADA systems allows for a comprehensive overview of the entire operation and facilitates coordinated control and monitoring of various systems.

It is important to ensure that the remote control and monitoring systems are implemented with appropriate cybersecurity measures to protect against unauthorized access or cyber threats. Manufacturers of RTOs often provide guidance and recommendations for implementing secure remote access to their systems.

Overall, the remote control and monitoring capabilities of RTOs enhance operational efficiency, enable proactive maintenance, and facilitate faster response times, contributing to the effective and optimized operation of the air pollution control system.

Can regenerative thermal oxidizers reduce odor emissions?

Regenerative thermal oxidizers (RTOs) are effective in reducing odor emissions from industrial processes. While their primary purpose is to control and destroy volatile organic compounds (VOCs) and hazardous air pollutants (HAPs), they can also effectively mitigate odorous compounds.

Here’s how RTOs contribute to odor reduction:

- Oxidation of Odorous Compounds: RTOs operate at high temperatures, typically ranging from 1,400 to 1,800 degrees Fahrenheit (760 to 980 degrees Celsius). These elevated temperatures facilitate the complete oxidation of odorous compounds, breaking them down into harmless byproducts, such as carbon dioxide and water vapor. The thermal oxidation process ensures the destruction of odor-causing molecules.

- High Destruction Efficiency: RTOs are designed to achieve high destruction efficiencies, often exceeding 99%. This means that the vast majority of odorous compounds are effectively eliminated during the combustion process, resulting in a significant reduction in odor emissions.

- Retention Time: RTOs provide a sufficiently long retention time for the exhaust gases within the combustion chamber. This allows for thorough mixing and residence time necessary for the complete oxidation of odorous compounds. The extended contact time ensures that the odorous molecules have sufficient exposure to the high temperatures, resulting in their destruction.

- Control of VOCs: Many odorous compounds are also VOCs. By effectively controlling and destroying VOC emissions, RTOs indirectly reduce odor emissions as well. The comprehensive destruction of VOCs prevents their release into the atmosphere, thereby minimizing the associated odors.

- Monitoring and Optimization: Proper monitoring and optimization of RTO operation can further enhance odor reduction. By continuously monitoring the process parameters, such as temperature, airflow, and pollutant concentrations, adjustments can be made to optimize the performance of the RTO and ensure effective odor control.

It’s important to note that while RTOs are effective in reducing odor emissions, the specific odor compounds and their concentrations in the exhaust stream can influence the overall odor control efficiency. Additionally, proper design, operation, and maintenance of the RTO are crucial for achieving optimal odor reduction.

editor by CX 2023-10-20