Основна информация.

Модел NO.

Невероятен RTO

Тип

Инсинератор

Висока ефективност

100

Less Maintenance

100

Easy for Operation

100

Икономия на енергия

100

Търговска марка

Бямазинг

Транспортен пакет

Overseas Wooden

Спецификация

180*24

Произход

Китай

Код по ХС

8416100000

Описание на продукта

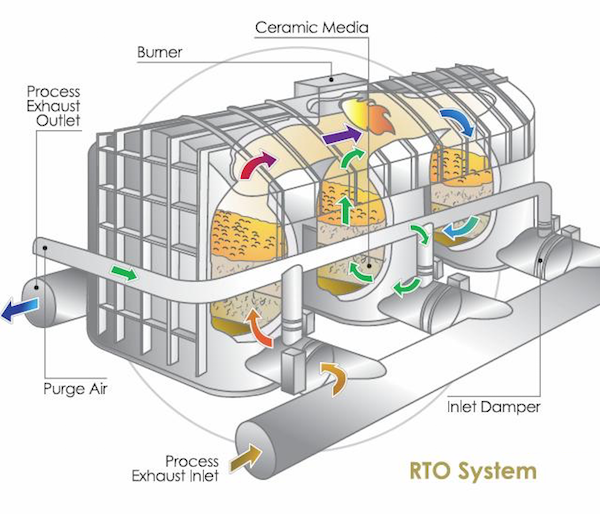

RTO

Регенеративен термичен окислител

Compared with traditional catalytic combustion, direct thermal oxidizer, RTO has the merits of high heating efficiency, low operation cost, and the ability to treat large flux low concentration waste gas. When VOCs concentration is high, secondary heat recycle can be realized, which will greatly reduce the operation cost. Because RTO can preheat the waste gas by levels through ceramic heat accumulator, which could make the waste gas to be completely heated and cracked with no dead corner(treatment efficiency>99%),which reduce the NOX in the Exhausting gas, if the VOC density >1500mg/Nm3, when the waste gas reach cracking area, it has been heated up to cracking temperature by heat accumulator, the burner will be closed under this condition.

RTO can be devided into chamber type and rotary type according to difference operation mode. Rotary type RTO has advantages in system pressure, temperature stability, investment amount, etc

Recuperative thermal oxidizer:

Compared with the catalytic combustion and regenerative thermal oxidation furnace, recuperative thermal oxidizer investment is less . Recuperative thermal oxidizer system can be designed for the entire incineration system as well as the new air system, which is more suitable for production characteristics of coating units for building materials plate.

| Burning type | Treatment system | ефективност | Advantage | Disadvantage | |

| Treating efficiency | Heat recycle rate | ||||

| High temperature incineration | Regenerative-RTO | 99 % | 80-97 % | Good product quality, low energy consumption, low cost in operational and minimum maintenance | Initial investment is somewhat of higher |

| Recuperative-RTO | 98 % | 40-70 % | When adopt full incinerating design, the energy consumption is low | High temperature joint interface is easy to broken, maintenance cost is high | |

| Low temperature incineration | Catalyzing-RCO | 98 % | 70-85 % | Low investment, low energy consumption | VOC concentration has to be controlled strictly, catalyst need to be changed regularly |

| Active carbon absorption | 90 % | Lower investment, self aggregation waste gas can be treated | Treatment efficiency is low, activated carbon particle need to be replaced regularly | ||

Regenerative Thermal Oxidizer, Regenerative Thermal Oxidizer, Recuperative Thermal Oxidizer, recuperative Thermal Oxidizer, recuperative Thermal Oxidizer, Thermal Oxidizer, oxidizer, oxidizer, oxidizer, incinerator, incinerator, incinerator, waste gas treatment, waste gas treatment, waste gas treatment, VOC treatment, VOC treatment, VOC treatment, RTO, RTO, RTO, RTO, RTO, RTO

Адрес: 8 етаж, E1, сграда Pinwei, път Dishengxi, Yizhuang, ZheJiang, Китай

Тип бизнес: производител/фабрика, търговска компания

Бизнес диапазон: Електротехника и електроника, Индустриално оборудване и компоненти, Машини за производство и обработка, Металургия, Минерали и енергия

Сертифициране на системата за управление: ISO 9001, ISO 14001

Основни продукти: Rto, линия за цветно покритие, линия за поцинковане, въздушен нож, резервни части за производствена линия, машина за нанасяне на покритие, независимо оборудване, ролка за мивки, проект за обновяване, вентилатор

Представяне на компанията: ZheJiang Amazing Science & Technology Co., Ltd е процъфтяваща високотехнологична компания, разположена в зоната за икономическо и технологично развитие на ZheJiang (BDA). Придържайки се към концепцията за реалистични, иновативни, фокусирани и ефективни, нашата компания обслужва главно обработката на отпадъчни газове (ЛОС) промишлеността и металургичното оборудване на Китай и дори на целия свят. Разполагаме с напреднали технологии и богат опит в проекта за третиране на отпадъчни газове с летливи органични съединения, чието позоваване е успешно приложено в индустрията за покрития, каучук, електроника, печат и т.н. Също така имаме години натрупване на технологии в изследването и производството на плоски линия за обработка на стомана и притежава близо 100 примера за приложение.

Нашата компания се фокусира върху проучването, проектирането, производството, инсталирането и пускането в експлоатация на система за третиране на органични отпадъчни газове с ЛОС и проект за обновяване и актуализиране на енергоспестяване и опазване на околната среда на линия за обработка на плоска стомана. Ние можем да предоставим на клиентите цялостни решения за опазване на околната среда, енергоспестяване, подобряване на качеството на продуктите и други аспекти.

Ние също така се занимаваме с различни резервни части и независимо оборудване за линия за цветно покритие, линия за поцинковане, линия за ецване, като валяк, съединител, топлообменник, рекуператор, въздушен нож, вентилатор, заварчик, изравнител на опън, кожен проход, разширителна фуга, срязване, фуги , шевна машина, горелка, лъчиста тръба, редуктор, редуктор и др.

Are regenerative thermal oxidizers suitable for controlling particulate matter emissions?

Regenerative thermal oxidizers (RTOs) are primarily designed for the destruction of volatile organic compounds (VOCs) and hazardous air pollutants (HAPs). While RTOs are highly effective in treating gaseous pollutants, they are not specifically designed for controlling particulate matter emissions.

Here are some key points to consider regarding the suitability of RTOs for controlling particulate matter emissions:

- Particulate Matter (PM) Removal Mechanism: RTOs primarily operate based on the thermal oxidation of pollutants. They rely on high temperatures to break down and destroy gaseous pollutants, but they do not have a dedicated mechanism for capturing and removing particulate matter. The design of RTOs does not incorporate features such as filters or electrostatic precipitators that are commonly used for effective particulate matter control.

- Limited Particulate Matter Destruction: While RTOs can provide some incidental removal of fine particulate matter through mechanisms like thermal decomposition and agglomeration, the removal efficiency for particulate matter is generally low compared to dedicated particulate control devices. The focus of RTOs is primarily on the destruction of gaseous pollutants rather than the capture and removal of particulates.

- Supplementary Particulate Control: In certain cases, supplementary particulate control devices may be integrated with RTOs to address particulate matter emissions. These devices, such as bag filters or electrostatic precipitators, can be installed downstream of the RTO to capture and remove particulates. This combination of an RTO with a separate particulate control device can help achieve comprehensive air pollution control for both gaseous pollutants and particulate matter.

- Consideration of Particulate Characteristics: When evaluating the suitability of RTOs for a specific application involving particulate matter emissions, it is crucial to consider the characteristics of the particulates, such as size, composition, and concentration. RTOs may be more effective in controlling certain types of coarse particulates compared to fine or ultrafine particulate matter.

- Alternative Technologies: For industries with significant particulate matter emissions, other air pollution control technologies specifically designed for particulate removal, such as fabric filters (baghouses), electrostatic precipitators, or wet scrubbers, may be more suitable and efficient.

In summary, while regenerative thermal oxidizers are highly effective for the destruction of gaseous pollutants, they are not specifically designed for controlling particulate matter emissions. If particulate matter control is a significant concern, supplementary particulate control devices or alternative technologies should be considered to ensure comprehensive air pollution control.

Can regenerative thermal oxidizers be used for treating emissions from paint booths?

Yes, regenerative thermal oxidizers (RTOs) can be effectively used for treating emissions from paint booths. Paint booths generate volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) during the painting process, which need to be controlled to comply with environmental regulations and ensure air quality. Here are some key points regarding the use of RTOs for treating emissions from paint booths:

- Контрол на емисиите: RTO са проектирани да постигнат висока ефективност на унищожаване на ЛОС и HAP. Тези замърсители се окисляват в RTO при високи температури, обикновено над 95% ефективност, превръщайки ги във въглероден диоксид (CO2) and water vapor. This ensures effective control and reduction of emissions from the paint booth.

- Paint Booth Compatibility: RTOs can be integrated into the exhaust system of paint booths, capturing and treating the emissions before they are released into the atmosphere. The RTO is typically connected to the exhaust stack of the paint booth, allowing the VOC-laden air to pass through the oxidizer for treatment.

- Thermal Capacity: Paint booth emissions can vary in terms of flow rate, temperature, and concentration of VOCs. RTOs are designed to handle a wide range of operating conditions and can accommodate high flow rates and elevated temperatures. The system’s thermal capacity ensures effective treatment of emissions from paint booths, even during peak production periods.

- Възстановяване на топлина: RTO включват системи за топлообмен, които позволяват възстановяване и повторно използване на топлинна енергия. Топлообменниците в рамките на RTO улавят топлината от изходящите отработени газове и я прехвърлят към входящия технологичен въздух или газов поток. Този процес на възстановяване на топлината подобрява цялостната енергийна ефективност на системата и намалява необходимостта от допълнителен разход на гориво.

- Съответствие с разпоредбите: Paint booth emissions are subject to regulatory requirements for air quality and emissions control. RTOs are capable of achieving the necessary destruction efficiencies and can help paint booth operators comply with environmental regulations. The use of RTOs demonstrates a commitment to sustainable practices and responsible management of air emissions.

It is important to note that the specific design and configuration of the RTO, as well as the characteristics of the paint booth emissions, should be considered when implementing an RTO for a paint booth application. Consulting with experienced engineers or RTO manufacturers can provide valuable insights into the proper sizing, integration, and performance requirements for treating emissions from paint booths.

In summary, RTOs are a suitable and effective technology for treating emissions from paint booths, providing high destruction efficiencies, compatibility with paint booth exhaust systems, thermal capacity for varying operating conditions, heat recovery, and compliance with environmental regulations.

What are the benefits of using a regenerative thermal oxidizer?

A regenerative thermal oxidizer (RTO) is an advanced air pollution control technology used in industrial processes to remove volatile organic compounds (VOCs), hazardous air pollutants (HAPs), and other harmful emissions. The use of an RTO offers several benefits:

1. High Destruction Efficiency: RTOs are known for their high destruction efficiency, typically achieving over 99% destruction of VOCs and HAPs. This effectiveness ensures that the majority of harmful pollutants are eliminated, resulting in cleaner air emissions and compliance with environmental regulations.

2. Energy Efficiency: RTOs are designed to be energy-efficient systems. They utilize a regenerative process that recovers and preheats the incoming process air by capturing and transferring heat from the outgoing exhaust stream. This heat recovery mechanism significantly reduces the energy consumption of the system, making RTOs a cost-effective solution for air pollution control.

3. Cost Savings: The energy efficiency of RTOs translates into cost savings for industrial operations. By reducing fuel consumption and operating costs, businesses can achieve long-term financial benefits. Additionally, the high destruction efficiency of RTOs eliminates the need for additional downstream pollution control equipment, reducing capital and maintenance expenses.

4. Thermal Self-Sustainability: RTOs have the unique ability to sustain their operating temperature without the need for external fuel sources. Once the system reaches the desired operating temperature, the heat recovery process maintains the necessary thermal energy for oxidation. This self-sustainability reduces reliance on external fuel, enhances system reliability, and minimizes operational downtime.

5. Flexibility and Adaptability: RTOs are versatile and can be designed to accommodate a wide range of process exhaust volumes and pollutant concentrations. They can handle varying flow rates, inlet temperatures, and pollutant loadings, making them suitable for diverse industrial applications. RTOs can be customized to meet specific process requirements, ensuring optimal performance and adaptability.

6. Low Maintenance Requirements: RTOs are known for their low maintenance requirements. The absence of complex moving parts and the self-sustaining nature of the system contribute to minimal maintenance needs. Routine inspections, periodic checks, and basic preventive maintenance are usually sufficient to keep the RTO operating efficiently. This reduces downtime and maintenance costs for industrial facilities.

7. Environmental Compliance: By effectively removing VOCs, HAPs, and other pollutants, RTOs enable industrial facilities to achieve and maintain compliance with environmental regulations. This ensures that the emissions from the manufacturing or process operations meet the required air quality standards, protecting the environment and surrounding communities.

The benefits of using a regenerative thermal oxidizer, including high destruction efficiency, energy efficiency, cost savings, thermal self-sustainability, flexibility, low maintenance requirements, and environmental compliance, make it a preferred choice for many industries seeking effective and sustainable air pollution control solutions.

editor by CX 2023-10-20