Basic Info.

Model NO.

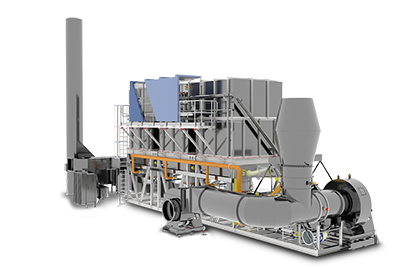

RTO

Tip

Environmental Monitoring Instrument

Main Function

Waste Gases Removal

Application

Chemical Industry

Brand

Raidsant

Clean Efficeincy

99.8%

Condition

New

Trademark

Raidsant

Transport Package

Film Wrapped

Origin

ZheJiang China

Product Description

HangZhou Raidsant Machinery Co.;,; Ltd.; is majored in developing and manufacturing innovativepowder cooling pelletizing machinery and related industrial waste gas treatment machine.; With nearly 20 years’ production history,; we have a good market in more than 20 provinces in China,; and some of our products were exported to Saudi Arabia,;Singapore,;Mexico,; Brazil,;Spain,; America,; Russia and Korea,; etc.;

Specifications:;

* More compact than the existing facilities

* Low-operation costs

* Long lifespan of facilities

* No changes in pressure

Purpose:;

Energy-saving system that burns volatile organic compound (VOC); and waste gas by using heat,; and it collects over 99.;8% of waste heat of exhaust gas by using ceramic regenerative materials (catalyst); with large surface area and low-pressure loss.;

Applications:;

1.; Painting drying process

2.; metal printing process

3.; fiber drying process

4.; adhesive tape process

5.; waste treatment process

6.; semiconductor manufacturing process

7.; smoke,; confectionary and baking process

8.; petrochemical process,;

9.; medicine and food manufacturing process,;

10.; other VOC generating process

Merits:;

* More compact than the existing facilities

* No changes in pressure

* High-heat recovery rate (over 95%);

* Perfect VOC treatment (over 99.;8%);

* Long lifespan of facilities

* Low-operation costs

* Able to be manufactured in circle or quadrangle

General Descriptions and Features:;

1.; Operating principle

Operation method that continuously changing discharges by rotating the Rotary Valve

2.; Process Pressure Change

No pressure change because wind direction changes in order by the Rotary Valve rotation

3.; Investment Costs

Around 70% of Bed Type

4.; Installation Space

It is single vessel so it is compact and requires less installation space.;

5.; Maintenance

It is easy to maintain it because Rotary Valve is the only 1 moving part.;

Rotary Valve’s sealing part is rarely worn out because it rotates at low speed.;

6.; Stability

No risks in the process because it is always opened even when the Rotary Valve has troubles.;

7.; Treatment Efficiency

Treatment efficiency maintains because sealing part is rarely worn out even if it is operated for a long time.;

Address: No.3,Zhenxin Middle Road, Economic Development Zone,HangZhou,ZheJiang

Business Type: Manufacturer/Factory, Trading Company

Business Range: Chemicals, Electrical & Electronics, Manufacturing & Processing Machinery, Security & Protection

Management System Certification: ISO 9001

Main Products: Pelletizer, Flaker, Pastillator, Granulator, Chemical Pelletizer, Vocs

Company Introduction: HangZhou Raidsant Machinery Co., Ltd. ., previously called HangZhou Xinte Plastic Machinery Factory is majored in producing innovative plastic recycling machinery. With nearly 20 years′ experience, we have a good market in 20 provinces in China, and some of our products were exported to Indonesia, Russia and Vietnam, etc. Our main products include DZ Type Pastillator, waste tire recycling line, Big Calibre Plastic Pipe shredders recycling line, continuous annealing tin-coation machine, QX type PET, PE & hull washing line, SDP double rails plastic recycling crusher, SJ hot cutting granule making unit, PVC tube (cinquefoil) product line, PVC Odd-shaped material product line for door and window, granule product line in water and Shredder for plastics and recycling. We acquired 5 technical patents.

Our corpotation lays emphsis on thchnical reconstruction, imports advanced technology from home and abroad, and develops new products constantly. Our tenet is challenging for hight quality, offering the best products. We are making efforts to realize our slogan. Satisfying our customers is our everlasting pursuit.

We are looking for the oversea customers or agents. If you are interested in our proposal, please let us know which of our products is the most likely to appeal to you or your customers. We should be very grateful if you give us some ideas of the marketprospects for our products. We hope to hear favorable information from you soon! It is our goal that we wish we could buid a good relationship with you now or in the near future. Please do not hesitate to contact us if you have any question or request.

We also sincerely welcome you to our company to discuss business and negotiate with us. For further expanding our market and customers, our company welcomes customer from domestic and aboard in an new-brand gesture on the basis of full-new mangement conception—quality, honour, service. We are looking for ISO 90001 mangement quality system to meet with our customers requirement!

Are regenerative thermal oxidizers suitable for small-scale applications?

Regenerative thermal oxidizers (RTOs) are primarily designed for medium to large-scale industrial applications due to their specific characteristics and operational requirements. However, their suitability for small-scale applications depends on various factors:

- Process Exhaust Volume: The exhaust volume generated by the small-scale application plays a crucial role in determining the feasibility of using an RTO. RTOs are typically designed to handle high exhaust volumes, and if the exhaust volume from the small-scale application is too low, it may not be cost-effective or efficient to use an RTO.

- Capital and Operating Costs: RTOs can be expensive to purchase, install, and operate. The capital investment required for a small-scale application may not be justifiable when considering the relatively lower exhaust volumes and pollutant concentrations. Additionally, the operating costs, including energy consumption and maintenance, may outweigh the benefits for small-scale operations.

- Space Availability: RTOs require a significant amount of physical space for installation. Small-scale applications may have space limitations, making it challenging to accommodate the size and layout requirements of an RTO system.

- Regulatory Requirements: Small-scale applications may be subject to different regulatory requirements compared to larger industrial operations. The specific emission limits and air quality standards applicable to the small-scale application should be considered to ensure compliance. Alternative emission control technologies that are more suitable for small-scale applications, such as catalytic oxidizers or biofilters, may be available.

- Process Characteristics: The nature of the small-scale application’s exhaust stream, including the type and concentration of pollutants, can influence the choice of emission control technology. RTOs are most effective for applications with high concentrations of volatile organic compounds (VOCs) and hazardous air pollutants (HAPs). If the pollutant profile of the small-scale application is different, alternative technologies may be more appropriate.

While RTOs are generally more suitable for medium to large-scale applications, it’s important to assess the specific requirements, constraints, and cost-benefit analysis for each individual small-scale application before considering the use of an RTO. Alternative emission control technologies that are better suited for small-scale operations should also be evaluated.

Are regenerative thermal oxidizers suitable for controlling emissions from food processing operations?

Yes, regenerative thermal oxidizers (RTOs) can be suitable for controlling emissions from food processing operations. Food processing operations often generate volatile organic compounds (VOCs) and odorous compounds that need to be controlled to comply with environmental regulations and maintain air quality. Here are some key points regarding the suitability of RTOs for controlling emissions from food processing operations:

- Emission Control: RTOs are designed to achieve high destruction efficiencies for VOCs and odorous compounds. These pollutants are oxidized within the RTO at high temperatures, typically above 95% efficiency, converting them into carbon dioxide (CO2) and water vapor. This ensures effective control and reduction of emissions from food processing operations.

- Process Compatibility: RTOs can be integrated into the exhaust systems of various food processing operations, capturing and treating the emissions before they are released into the atmosphere. The RTO is typically connected to the process equipment or exhaust stack, allowing the VOC-laden air to pass through the oxidizer for treatment.

- Flexibility: RTOs offer flexibility in handling a wide range of operating conditions and pollutants. Food processing operations can vary in terms of flow rates, temperature, and composition of emissions. RTOs are designed to accommodate these variations and provide effective treatment even under fluctuating conditions.

- Odor Control: In addition to VOCs, food processing operations can also generate odorous compounds, which can cause nuisance and odor-related complaints. RTOs can be equipped with additional odor control technologies such as activated carbon beds or scrubbers to address odor concerns and ensure the removal of unpleasant odors.

- Compliance with Regulations: Food processing operations are subject to regulatory requirements for air quality and emissions control. RTOs are capable of achieving the necessary destruction efficiencies and can help food processors comply with environmental regulations. The use of RTOs demonstrates a commitment to sustainable practices and responsible management of air emissions.

It is important to note that the specific design and configuration of the RTO, as well as the characteristics of the food processing emissions, should be considered when implementing an RTO for a specific application. Consulting with experienced engineers or RTO manufacturers can provide valuable insights into the proper sizing, integration, and performance requirements for controlling emissions from food processing operations.

In summary, RTOs are a suitable and effective technology for controlling emissions from food processing operations, providing high destruction efficiencies, compatibility with various processes, flexibility in handling operating conditions, odor control capabilities, and compliance with environmental regulations.

Regenerative Thermal Oxidizer vs. Thermal Oxidizer

When comparing a regenerative thermal oxidizer (RTO) to a conventional thermal oxidizer, there are several key differences to consider:

1. Operation:

A regenerative thermal oxidizer operates using a cyclical process that involves heat recovery, while a thermal oxidizer typically operates in a continuous mode without heat recovery.

2. Heat Recovery:

One of the primary distinctions between the two systems is the heat recovery mechanism. An RTO utilizes heat exchanger beds filled with ceramic media or structured packing to recover heat from the outgoing gases and preheat the incoming gases, resulting in energy savings. In contrast, a thermal oxidizer does not incorporate heat recovery, leading to higher energy consumption.

3. Efficiency:

RTOs are known for their high destruction efficiency, typically above 95%, which enables effective removal of volatile organic compounds (VOCs) and other pollutants. Thermal oxidizers, on the other hand, may have slightly lower destruction efficiencies depending on the specific design and operating conditions.

4. Energy Consumption:

Due to the heat recovery mechanism, RTOs generally require less energy for operation compared to thermal oxidizers. The preheating of incoming gases in an RTO reduces the fuel consumption required for combustion, making it more energy-efficient.

5. Cost-effectiveness:

While the initial capital investment for an RTO can be higher than that of a thermal oxidizer due to the heat recovery components, the long-term operational cost savings through energy recovery and higher destruction efficiencies make RTOs a cost-effective solution over the lifespan of the system.

6. Environmental Compliance:

Both RTOs and thermal oxidizers are designed to meet emissions regulations and help industries comply with air quality standards and permits. However, RTOs typically offer higher destruction efficiencies, which can enhance environmental compliance.

7. Versatility:

RTOs and thermal oxidizers are both versatile in terms of handling a wide range of process exhaust volumes and pollutant concentrations. However, RTOs are often preferred for applications where high destruction efficiencies and energy recovery are critical.

Overall, the key distinctions between a regenerative thermal oxidizer and a thermal oxidizer lie in the heat recovery mechanism, energy consumption, efficiency, and cost-effectiveness. RTOs offer superior energy recovery and higher destruction efficiencies, making them an attractive option for industries that prioritize energy efficiency and environmental compliance.

editor by CX 2024-04-09