Basic Info.

Model NO.

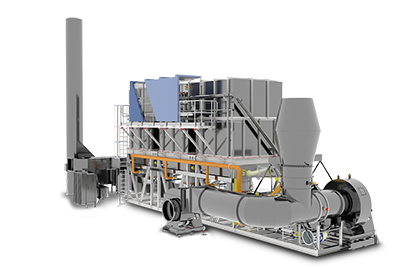

Amazing RTO

Tip

Incinerator

Energy Saving

100

Easy for Operation

100

High Efficiency

100

Less Maintenance

100

Trademark

Bjamazing

Transport Package

Overseas Wooden

Specification

180*24

Origin

China

HS Code

8416100000

Product Description

RTO

Oxidant termic regenerativ

Compared with traditional catalytic combustion,; direct thermal oxidizer,; RTO has the merits of high heating efficiency,; low operation cost,; and the ability to treat large flux low concentration waste gas.; When VOCs concentration is high,; secondary heat recycle can be realized,; which will greatly reduce the operation cost.; Because RTO can preheat the waste gas by levels through ceramic heat accumulator,; which could make the waste gas to be completely heated and cracked with no dead corner(treatment efficiency>99%);,;which reduce the NOX in the Exhausting gas,; if the VOC density >1500mg/Nm3,; when the waste gas reach cracking area,; it has been heated up to cracking temperature by heat accumulator,; the burner will be closed under this condition.;

RTO can be devided into chamber type and rotary type according to difference operation mode.; Rotary type RTO has advantages in system pressure,; temperature stability,; investment amount,; etc

Recuperative thermal oxidizer:;

Compared with the catalytic combustion and regenerative thermal oxidation furnace,; recuperative thermal oxidizer investment is less .; Recuperative thermal oxidizer system can be designed for the entire incineration system as well as the new air system,; which is more suitable for production characteristics of coating units for building materials plate.;

| Burning type | Treatment system | eficienţă | Advantage | Disadvantage | |

| Treating efficiency | Heat recycle rate | ||||

| High temperature incineration | Regenerative-RTO | 99 % | 80-97 % | Good product quality,; low energy consumption,; low cost in operational and minimum maintenance | Initial investment is somewhat of higher |

| Recuperative-RTO | 98 % | 40-70 % | When adopt full incinerating design,; the energy consumption is low | High temperature joint interface is easy to broken,; maintenance cost is high | |

| Low temperature incineration | Catalyzing-RCO | 98 % | 70-85 % | Low investment,; low energy consumption | VOC concentration has to be controlled strictly,; catalyst need to be changed regularly |

| Active carbon absorption | 90 % | Lower investment,; self aggregation waste gas can be treated | Treatment efficiency is low,; activated carbon particle need to be replaced regularly | ||

Regenerative Thermal Oxidizer,; Regenerative Thermal Oxidizer,; Recuperative Thermal Oxidizer,; recuperative Thermal Oxidizer,; recuperative Thermal Oxidizer,; Thermal Oxidizer,; oxidizer,; oxidizer,; oxidizer,; incinerator,; incinerator,; incinerator,; waste gas treatment,; waste gas treatment,; waste gas treatment,; VOC treatment,; VOC treatment,; VOC treatment,; RTO,; RTO,; RTO,; RTO,; RTO,; RTO

Address: 8 floor, E1, Pinwei building, Dishengxi road, Yizhuang, ZheJiang , China

Business Type: Manufacturer/Factory, Trading Company

Business Range: Electrical & Electronics, Industrial Equipment & Components, Manufacturing & Processing Machinery, Metallurgy, Mineral & Energy

Management System Certification: ISO 9001, ISO 14001

Main Products: Rto, Color Coating Line, Galvanizing Line, Air Knife, Spares for Processing Line, Coater, Independent Equipments, Sink Roll, Revamping Project, Blower

Company Introduction: ZheJiang Amazing Science & Technology Co., Ltd is a thriving Hi-tech company, located in ZheJiang Economic and Technological Development Area(BDA). Adhering to the concept of Realistic, Innovative, Focused and Efficient, our company mainly serve the waste gas treatment (VOCs) Industry and metallurgical equipment of China and even whole world. We have advanced technology and rich experience in VOCs waste gas treatment project, the reference of which has been successfully applied to the industry of coating, rubber, electronic, printing, etc. We also have years of technology accumulation in the research and manufacturing of flat steel processing line, and possess nearly 100 of application example.

Our company focus on the research, design, manufacturing, installation and commissioning of VOCs organic waste gas treatment system and the revamping and updating project for energy saving and environmental protection of flat steel processing line. We can provide customers the complete solutions for environmental protection, energy saving, product quality improvement and other aspects.

We are also engaged in various spares and independent equipment for color coating line, galvanizing line, pickling line, like roller, coupler, heat exchanger, recuperator, air knife, blower, welder, tension leveler, skin pass, expansion joint, shear, jointer, stitcher, burner, radiant tube, gear motor, reducer, etc.

Are there any incentives or grants available for installing regenerative thermal oxidizers?

Yes, there are various incentives and grants available that can help offset the cost of installing regenerative thermal oxidizers (RTOs) and other emission control technologies. These incentives are typically offered by government agencies at the local, regional, and national levels to promote environmental sustainability, air quality improvement, and compliance with emissions regulations. However, the availability and specific details of these incentives may vary depending on the location and the specific program.

Here are some examples of incentives and grants that may be available:

- Energy Efficiency Grants: Many government agencies and utility companies offer grants and financial incentives to encourage energy efficiency measures, including the installation of energy-efficient equipment like RTOs. These grants can help offset a portion of the installation costs and may be based on factors such as energy savings, reduction in greenhouse gas emissions, or specific environmental objectives.

- Environmental Grant Programs: Some governmental organizations or environmental foundations provide grants specifically targeted at reducing emissions and improving air quality. These grants may be available for industries or businesses that invest in emission control technologies, such as RTOs, to help them comply with regulations and improve their environmental performance.

- Tax Incentives and Credits: Certain jurisdictions offer tax incentives or credits to businesses or industries that invest in environmentally friendly technologies. These incentives can significantly reduce the overall cost of installing an RTO. Examples include tax credits for energy-efficient equipment, accelerated depreciation allowances, or exemptions from sales tax on eligible equipment purchases.

- Industry-Specific Programs: Some industries or sectors may have specific grant programs or incentives tailored to their unique environmental challenges. These programs may provide financial assistance for emission control projects, including the installation of RTOs, within those industries.

- Research and Development Funding: Government agencies or research organizations often provide funding opportunities for the development and implementation of innovative emission control technologies. Businesses or research institutions involved in developing advanced RTO designs or improving RTO efficiency may be eligible for research grants or funding support.

To explore the availability of incentives and grants for installing RTOs, it is recommended to contact local environmental agencies, energy efficiency programs, or business development organizations. These entities can provide information on specific incentive programs, eligibility criteria, application procedures, and any deadlines or limitations associated with the grants.

It’s important to note that incentive programs may change over time, and their availability may depend on factors such as funding allocations and government policies. Therefore, it is advisable to stay updated with the latest information and consult with relevant authorities to determine the current incentives available for installing RTOs.

Are regenerative thermal oxidizers suitable for controlling emissions from food processing operations?

Yes, regenerative thermal oxidizers (RTOs) can be suitable for controlling emissions from food processing operations. Food processing operations often generate volatile organic compounds (VOCs) and odorous compounds that need to be controlled to comply with environmental regulations and maintain air quality. Here are some key points regarding the suitability of RTOs for controlling emissions from food processing operations:

- Emission Control: RTOs are designed to achieve high destruction efficiencies for VOCs and odorous compounds. These pollutants are oxidized within the RTO at high temperatures, typically above 95% efficiency, converting them into carbon dioxide (CO2) and water vapor. This ensures effective control and reduction of emissions from food processing operations.

- Process Compatibility: RTOs can be integrated into the exhaust systems of various food processing operations, capturing and treating the emissions before they are released into the atmosphere. The RTO is typically connected to the process equipment or exhaust stack, allowing the VOC-laden air to pass through the oxidizer for treatment.

- Flexibility: RTOs offer flexibility in handling a wide range of operating conditions and pollutants. Food processing operations can vary in terms of flow rates, temperature, and composition of emissions. RTOs are designed to accommodate these variations and provide effective treatment even under fluctuating conditions.

- Odor Control: In addition to VOCs, food processing operations can also generate odorous compounds, which can cause nuisance and odor-related complaints. RTOs can be equipped with additional odor control technologies such as activated carbon beds or scrubbers to address odor concerns and ensure the removal of unpleasant odors.

- Compliance with Regulations: Food processing operations are subject to regulatory requirements for air quality and emissions control. RTOs are capable of achieving the necessary destruction efficiencies and can help food processors comply with environmental regulations. The use of RTOs demonstrates a commitment to sustainable practices and responsible management of air emissions.

It is important to note that the specific design and configuration of the RTO, as well as the characteristics of the food processing emissions, should be considered when implementing an RTO for a specific application. Consulting with experienced engineers or RTO manufacturers can provide valuable insights into the proper sizing, integration, and performance requirements for controlling emissions from food processing operations.

In summary, RTOs are a suitable and effective technology for controlling emissions from food processing operations, providing high destruction efficiencies, compatibility with various processes, flexibility in handling operating conditions, odor control capabilities, and compliance with environmental regulations.

How efficient are regenerative thermal oxidizers in destroying volatile organic compounds (VOCs)?

Regenerative thermal oxidizers (RTOs) are highly efficient in destroying volatile organic compounds (VOCs) emitted from industrial processes. Here are the reasons why RTOs are considered efficient in VOC destruction:

1. High Destruction Efficiency: RTOs are known for their high destruction efficiency, typically exceeding 99%. They effectively oxidize VOCs present in the industrial exhaust streams, converting them into less harmful byproducts, such as carbon dioxide and water vapor. This high destruction efficiency ensures that the majority of VOCs are eliminated, resulting in cleaner emissions and compliance with environmental regulations.

2. Residence Time: RTOs provide a sufficiently long residence time for the combustion of VOCs. In the RTO chamber, the VOC-laden air is directed through a ceramic media bed, which acts as a heat sink. The VOCs are heated to the combustion temperature and react with the available oxygen, leading to their destruction. The design of RTOs ensures that the VOCs have ample time to undergo complete combustion before being released into the atmosphere.

3. Temperature Control: RTOs maintain the combustion temperature within a specific range to optimize VOC destruction. The operating temperature is carefully controlled based on factors such as the type of VOCs, their concentration, and the specific requirements of the industrial process. By controlling the temperature, RTOs ensure that the VOCs are efficiently oxidized, maximizing destruction efficiency while minimizing the formation of harmful byproducts, such as nitrogen oxides (NOx).

4. Heat Recovery: RTOs incorporate a regenerative heat recovery system, which enhances their overall energy efficiency. The system captures and preheats the incoming process air by utilizing the heat energy from the outgoing exhaust stream. This heat recovery mechanism minimizes the amount of external fuel required to sustain the combustion temperature, resulting in energy savings and cost-effectiveness. The heat recovery also helps maintain the high destruction efficiency of VOCs by providing a consistent and optimized operating temperature.

5. Catalyst Integration: In some cases, RTOs can be equipped with catalyst beds to further enhance VOC destruction efficiency. Catalysts can accelerate the oxidation process and lower the required operating temperature, improving the overall efficiency of VOC destruction. Catalyst integration is particularly beneficial for processes with lower VOC concentrations or when specific VOCs require lower temperatures for effective oxidation.

6. Compliance with Regulations: The high destruction efficiency of RTOs ensures compliance with environmental regulations governing VOC emissions. Many industrial sectors are subject to stringent air quality standards and emission limits. RTOs provide an effective solution for meeting these requirements by reliably and efficiently destroying VOCs, reducing their impact on air quality and public health.

In summary, regenerative thermal oxidizers (RTOs) are highly efficient in destroying volatile organic compounds (VOCs). Their high destruction efficiency, residence time, temperature control, heat recovery capabilities, optional catalyst integration, and compliance with regulations make RTOs a preferred choice for industries seeking effective and sustainable solutions for VOC abatement.

editor by CX 2024-03-10