Maklumat Asas.

Model NO.

RTO yang menakjubkan

taip

Insinerator

Penjimatan Tenaga

100

Easy for Operation

100

Kecekapan Tinggi

100

Less Maintenance

100

Tanda dagangan

Bjamazing

Pakej Pengangkutan

Overseas Wooden

Spesifikasi

180*24

asal usul

China

Kod HS

8416100000

Penerangan Produk

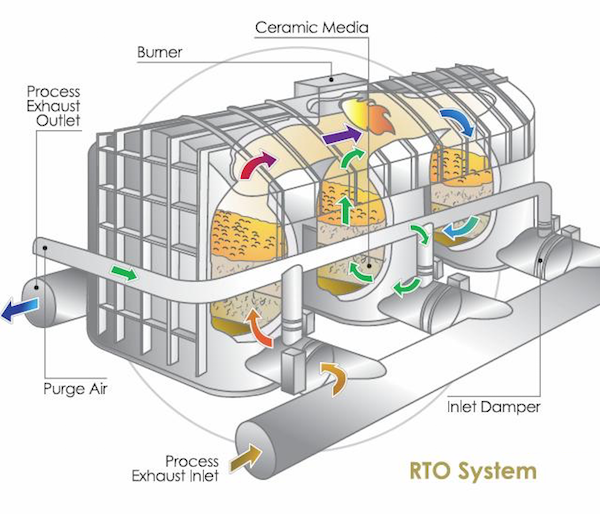

RTO

Pengoksida Terma Penjanaan Semula

Berbanding dengan pembakaran pemangkin tradisional,; pengoksida haba langsung,; RTO mempunyai merit kecekapan pemanasan yang tinggi,; kos operasi yang rendah,; dan keupayaan untuk merawat gas buangan kepekatan rendah fluks besar.; Apabila kepekatan VOC tinggi,; kitar semula haba sekunder boleh direalisasikan,; yang akan mengurangkan kos operasi.; Kerana RTO boleh memanaskan gas sisa mengikut tahap melalui penumpuk haba seramik,; yang boleh membuat gas buangan dipanaskan sepenuhnya dan retak tanpa sudut mati (kecekapan rawatan> 99%);,; yang mengurangkan NOX dalam gas yang meletihkan,; jika ketumpatan VOC >1500mg/Nm3,; apabila gas buangan mencapai kawasan retak,; ia telah dipanaskan sehingga suhu retak oleh penumpuk haba,; penunu akan ditutup di bawah keadaan ini.;

RTO boleh dibahagikan kepada jenis ruang dan jenis berputar mengikut mod operasi perbezaan.; RTO jenis Rotary mempunyai kelebihan dalam tekanan sistem,; kestabilan suhu,; jumlah pelaburan,; dll

Recuperative thermal oxidizer:;

Compared with the catalytic combustion and regenerative thermal oxidation furnace,; recuperative thermal oxidizer investment is less .; Recuperative thermal oxidizer system can be designed for the entire incineration system as well as the new air system,; which is more suitable for production characteristics of coating units for building materials plate.;

| Burning type | Treatment system | kecekapan | Advantage | Disadvantage | |

| Treating efficiency | Heat recycle rate | ||||

| High temperature incineration | Regenerative-RTO | 99% | 80-97 % | Good product quality,; low energy consumption,; low cost in operational and minimum maintenance | Initial investment is somewhat of higher |

| Recuperative-RTO | 98 % | 40-70 % | When adopt full incinerating design,; the energy consumption is low | High temperature joint interface is easy to broken,; maintenance cost is high | |

| Low temperature incineration | Catalyzing-RCO | 98 % | 70-85 % | Low investment,; low energy consumption | VOC concentration has to be controlled strictly,; catalyst need to be changed regularly |

| Active carbon absorption | 90 % | Lower investment,; self aggregation waste gas can be treated | Treatment efficiency is low,; activated carbon particle need to be replaced regularly | ||

Regenerative Thermal Oxidizer,; Regenerative Thermal Oxidizer,; Recuperative Thermal Oxidizer,; recuperative Thermal Oxidizer,; recuperative Thermal Oxidizer,; Thermal Oxidizer,; oxidizer,; oxidizer,; oxidizer,; incinerator,; incinerator,; incinerator,; waste gas treatment,; waste gas treatment,; waste gas treatment,; VOC treatment,; VOC treatment,; VOC treatment,; RTO,; RTO,; RTO,; RTO,; RTO,; RTO

Alamat: tingkat 8, E1, bangunan Pinwei, jalan Dishengxi, Yizhuang, ZheJiang, China

Jenis Perniagaan: Pengeluar/Kilang, Syarikat Perdagangan

Julat Perniagaan: Elektrik & Elektronik, Peralatan & Komponen Industri, Jentera Pembuatan & Pemprosesan, Metalurgi, Mineral & Tenaga

Pensijilan Sistem Pengurusan: ISO 9001, ISO 14001

Produk Utama: Rto, Talian Salutan Warna, Talian Galvanisasi, Pisau Udara, Alat Ganti untuk Talian Pemprosesan, Coater, Peralatan Bebas, Gulung Sink, Projek Ubahsuai, Blower

Pengenalan Syarikat: ZheJiang Amazing Science & Technology Co., Ltd ialah sebuah syarikat berteknologi tinggi yang berkembang maju, terletak di ZheJiang Economic and Technological Development Area(BDA). Berpegang kepada konsep Realistik, Inovatif, Fokus dan Cekap, syarikat kami menyediakan perkhidmatan terutamanya dalam industri rawatan gas sisa (VOC) dan peralatan metalurgi China dan juga seluruh dunia. Kami mempunyai teknologi canggih dan pengalaman yang kaya dalam projek rawatan gas buangan VOC, yang rujukannya telah berjaya digunakan untuk industri salutan, getah, elektronik, percetakan, dll. Kami juga mempunyai pengumpulan teknologi selama bertahun-tahun dalam penyelidikan dan pembuatan flat talian pemprosesan keluli, dan mempunyai hampir 100 contoh aplikasi.

Syarikat kami menumpukan pada penyelidikan, reka bentuk, pengilangan, pemasangan dan pentauliahan sistem rawatan gas sisa organik VOC dan projek merombak dan mengemas kini untuk penjimatan tenaga dan perlindungan alam sekitar barisan pemprosesan keluli rata. Kami boleh menyediakan pelanggan penyelesaian lengkap untuk perlindungan alam sekitar, penjimatan tenaga, peningkatan kualiti produk dan aspek lain.

Kami juga terlibat dalam pelbagai alat ganti dan peralatan bebas untuk garis salutan warna, garis galvanizing, garis penjerukan, seperti penggelek, pengganding, penukar haba, recuperator, pisau udara, peniup, pengimpal, penyamara ketegangan, pas kulit, sambungan pengembangan, ricih, penyambung , penjahit, penunu, tiub berseri, motor gear, pengurang, dsb.

Are regenerative thermal oxidizers suitable for controlling particulate matter emissions?

Regenerative thermal oxidizers (RTOs) are primarily designed for the destruction of volatile organic compounds (VOCs) and hazardous air pollutants (HAPs). While RTOs are highly effective in treating gaseous pollutants, they are not specifically designed for controlling particulate matter emissions.

Here are some key points to consider regarding the suitability of RTOs for controlling particulate matter emissions:

- Particulate Matter (PM) Removal Mechanism: RTOs primarily operate based on the thermal oxidation of pollutants. They rely on high temperatures to break down and destroy gaseous pollutants, but they do not have a dedicated mechanism for capturing and removing particulate matter. The design of RTOs does not incorporate features such as filters or electrostatic precipitators that are commonly used for effective particulate matter control.

- Limited Particulate Matter Destruction: While RTOs can provide some incidental removal of fine particulate matter through mechanisms like thermal decomposition and agglomeration, the removal efficiency for particulate matter is generally low compared to dedicated particulate control devices. The focus of RTOs is primarily on the destruction of gaseous pollutants rather than the capture and removal of particulates.

- Supplementary Particulate Control: In certain cases, supplementary particulate control devices may be integrated with RTOs to address particulate matter emissions. These devices, such as bag filters or electrostatic precipitators, can be installed downstream of the RTO to capture and remove particulates. This combination of an RTO with a separate particulate control device can help achieve comprehensive air pollution control for both gaseous pollutants and particulate matter.

- Consideration of Particulate Characteristics: When evaluating the suitability of RTOs for a specific application involving particulate matter emissions, it is crucial to consider the characteristics of the particulates, such as size, composition, and concentration. RTOs may be more effective in controlling certain types of coarse particulates compared to fine or ultrafine particulate matter.

- Alternative Technologies: For industries with significant particulate matter emissions, other air pollution control technologies specifically designed for particulate removal, such as fabric filters (baghouses), electrostatic precipitators, or wet scrubbers, may be more suitable and efficient.

In summary, while regenerative thermal oxidizers are highly effective for the destruction of gaseous pollutants, they are not specifically designed for controlling particulate matter emissions. If particulate matter control is a significant concern, supplementary particulate control devices or alternative technologies should be considered to ensure comprehensive air pollution control.

Are regenerative thermal oxidizers suitable for controlling emissions from printing presses?

Yes, regenerative thermal oxidizers (RTOs) can be suitable for controlling emissions from printing presses. Printing presses can emit volatile organic compounds (VOCs) and other air pollutants during the printing process, which need to be properly controlled to comply with environmental regulations and ensure air quality. Here are some key points regarding the suitability of RTOs for controlling emissions from printing presses:

- Kawalan pelepasan: RTOs are designed to achieve high destruction efficiencies for VOCs and hazardous air pollutants (HAPs). These pollutants are oxidized within the RTO at high temperatures, typically above 95% efficiency, converting them into carbon dioxide (CO2) and water vapor. RTOs effectively control and reduce emissions from printing presses.

- Compatibility: RTOs can be integrated into the exhaust system of printing presses, capturing and treating the emissions before they are released into the atmosphere. The RTO is typically connected to the exhaust stack of the printing press, allowing the VOC-laden air to pass through the oxidizer for treatment.

- High Flow Rates: Printing presses can generate significant exhaust volumes due to the printing process. RTOs are designed to handle high flow rates and can accommodate the varying exhaust volumes of printing presses. This ensures effective treatment of emissions even during peak production periods.

- Kapasiti Terma: RTOs have the thermal capacity to handle the temperature variations in printing press emissions. The printing process can result in varying exhaust temperatures, and RTOs are designed to operate effectively within a wide range of temperature conditions.

- Energy Efficiency: RTO menggabungkan sistem pertukaran haba yang membolehkan pemulihan dan penggunaan semula tenaga haba. Penukar haba dalam RTO menangkap haba daripada gas ekzos yang keluar dan memindahkannya ke aliran udara atau gas proses masuk. Proses pemulihan haba ini meningkatkan kecekapan tenaga keseluruhan sistem dan mengurangkan keperluan untuk penggunaan bahan api tambahan.

- Pematuhan dengan Peraturan: Printing press emissions are subject to regulatory requirements for air quality and emissions control. RTOs are capable of achieving the necessary destruction efficiencies and can help printing press operators comply with environmental regulations. The use of RTOs demonstrates a commitment to sustainable practices and responsible management of air emissions.

It is important to note that the specific design and configuration of the RTO, as well as the characteristics of the printing press emissions, should be considered when implementing an RTO for a printing press application. Consulting with experienced engineers or RTO manufacturers can provide valuable insights into the proper sizing, integration, and performance requirements for controlling emissions from printing presses.

In summary, RTOs are a suitable technology for controlling emissions from printing presses, providing high destruction efficiencies, compatibility with printing press exhaust systems, handling high flow rates and temperature variations, energy efficiency through heat recovery, and compliance with environmental regulations.

Are regenerative thermal oxidizers environmentally friendly?

Regenerative thermal oxidizers (RTOs) are considered environmentally friendly air pollution control devices due to several reasons:

- High Efficiency in Pollutant Destruction: RTOs are highly efficient in destroying pollutants, including volatile organic compounds (VOCs) and hazardous air pollutants (HAPs). They typically achieve destruction efficiencies exceeding 99%. This means that the vast majority of harmful pollutants are converted into harmless byproducts, such as carbon dioxide and water vapor.

- Compliance with Emission Regulations: RTOs help industries comply with stringent air quality regulations and emission limits set by environmental agencies. By effectively removing pollutants from industrial exhaust streams, RTOs help reduce the release of harmful substances into the atmosphere, contributing to improved air quality.

- Minimal Secondary Pollutant Formation: RTOs minimize the formation of secondary pollutants. The high temperatures within the combustion chamber promote the complete oxidation of pollutants, preventing the formation of uncontrolled byproducts, such as dioxins and furans, which can be more harmful than the original pollutants.

- Energy Efficiency: RTOs incorporate heat recovery systems that improve energy efficiency. They capture and utilize the heat generated during the oxidation process to preheat the incoming process air, reducing the energy requirements for heating. This energy recovery feature helps minimize the overall environmental impact of the system.

- Reduction of Greenhouse Gas Emissions: By effectively destroying VOCs and HAPs, RTOs contribute to the reduction of greenhouse gas emissions. VOCs are significant contributors to the formation of ground-level ozone and are associated with climate change. By eliminating VOC emissions, RTOs help mitigate the environmental impact associated with these pollutants.

- Applicability to Various Industries: RTOs are widely applicable across different industries and processes. They can handle a wide range of exhaust volumes, pollutant concentrations, and variations in gas composition, making them versatile and adaptable to various industrial applications.

While RTOs offer significant environmental benefits, it’s important to note that their overall environmental performance depends on proper design, operation, and maintenance. Regular inspections, maintenance, and adherence to manufacturer’s guidelines are crucial to ensuring the continued effectiveness and environmental friendliness of RTOs.

editor by Dream 2024-05-10