What are the environmental impact assessments for RTO in the coating industry?

はじめに

In the coating industry, the use of Regenerative Thermal Oxidizers (RTOs) has become increasingly prevalent due to their ability to effectively control and minimize air pollution. RTOs are advanced air pollution control systems that utilize high temperatures to destroy volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) emitted during the coating process. However, it is essential to conduct thorough environmental impact assessments to evaluate the potential effects of RTOs on the environment. This article aims to explore the various aspects and considerations involved in conducting environmental impact assessments for RTOs in the coating industry.

Assessment of Air Quality

– Measurement of VOC and HAP emissions

– Evaluation of air dispersion modeling

– Assessment of ambient air quality standards

– Monitoring of air pollutant concentrations near RTOs

– Analysis of the impact of RTOs on regional air quality

Energy Consumption and Efficiency

– Calculation of energy consumption by RTOs

– Assessment of energy efficiency improvements

– Comparison of energy consumption with alternative technologies

– Analysis of the potential for energy recovery from RTOs

– Evaluation of the overall environmental benefits of energy-efficient RTO systems

Waste Generation and Management

– Identification of waste streams from RTO operation

– Evaluation of waste treatment and disposal methods

– Assessment of the potential for waste reduction and recycling

– Analysis of the environmental impact of waste generated by RTOs

– Implementation of proper waste management practices

Health and Safety Considerations

– Identification of potential health risks associated with RTO emissions

– Assessment of worker exposure to VOCs and HAPs

– Analysis of the effectiveness of RTOs in reducing health hazards

– Evaluation of occupational health and safety measures

– Implementation of proper safety protocols and equipment

規制遵守

– Review of applicable environmental regulations and standards

– Assessment of RTO compliance with emission limits

– Analysis of permit requirements and reporting obligations

– Evaluation of the effectiveness of monitoring and control systems

– Compliance with local, national, and international environmental regulations

結論

In conclusion, conducting comprehensive environmental impact assessments for RTOs in the coating industry is crucial to ensure the effective control of air pollution and minimize environmental harm. By assessing air quality, energy consumption, waste generation, health and safety considerations, and regulatory compliance, the coating industry can make informed decisions regarding the implementation and operation of RTO systems. It is essential to prioritize sustainability and environmental protection to create a more sustainable and responsible coating industry.

Environmental Impact Assessments for RTO in the Coating Industry

Company Introduction:

Our company is a high-tech manufacturing enterprise specializing in the comprehensive treatment of volatile organic compounds (VOCs) exhaust gas and carbon reduction energy-saving technology. We have four core technologies: thermal energy, combustion, sealing, and self-control. We have the ability to simulate temperature fields and airflow fields, as well as the ability to test the properties of ceramic heat storage materials, select zeolite molecular sieve adsorption materials, and conduct high-temperature incineration and oxidation tests on VOCs organic substances.

Team Advantages:

We have an RTO technology research and development center and a waste gas carbon reduction engineering technology center in Xi’an, as well as a 30,000-square-meter production base in Yangling. We are a leading manufacturer of RTO equipment and zeolite molecular sieve rotary equipment worldwide. Our core technical team comes from the Aerospace Liquid Rocket Engine Research Institute (Aerospace Six Institute). We have more than 360 employees, including over 60 research and development technical backbones, including 3 senior engineers, 6 senior engineers, and 115 thermodynamic doctors.

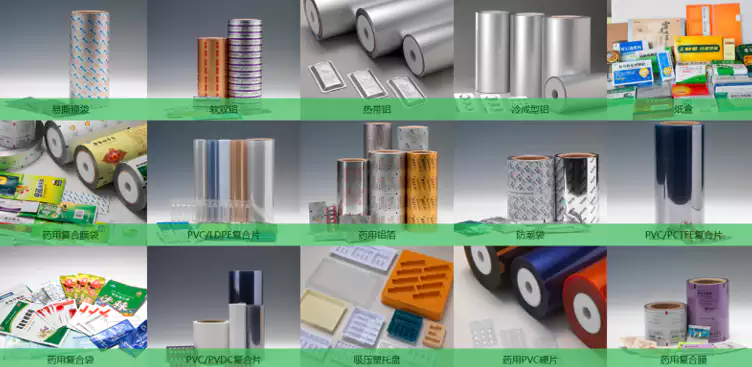

Core Products:

Our core products are the Rotary Valve Regenerative Thermal Oxidizer (RTO) and the zeolite molecular sieve adsorption and concentration rotary wheel. Combined with our expertise in environmental protection and thermal energy system engineering technology, we can provide customers with comprehensive solutions for industrial waste gas treatment, carbon reduction, and energy utilization under various operating conditions.

Certifications and Qualifications:

- Management System Certification for Intellectual Property Rights

- 品質管理システム認証

- 環境マネジメントシステム認証

- 建設業企業資格

- ハイテク企業

- Patents for Rotary Valve Regenerative Thermal Oxidizer and Rotary Wheel Heat Storage Incineration Equipment

- ディスクゼオライトロータリーホイールの特許

Choosing the Right RTO for the Coating Industry:

- 排気ガスの特性を判断する

- 地域の規制と排出基準を理解する

- エネルギー効率を評価する

- 運用とメンテナンスを考慮する

- 予算とコストの分析を実施する

- Select the appropriate type of RTO

- 環境と安全の要素を考慮する

- パフォーマンステストと検証を実行する

Regenerative Thermal Oxidizers Service Process:

- Initial consultation, on-site inspection, and needs analysis

- Solution design, simulation, and proposal review

- カスタマイズされた生産、品質管理、工場テスト

- オンサイト設置、試運転、トレーニングサービス

- 定期的なメンテナンス、技術サポート、スペアパーツの供給

We are a one-stop solution for RTO and have a professional team to tailor RTO solutions for our customers.

Successful Cases of RTO for the Coating Industry:

Case 1: A company in Shanghai specializes in functional films such as diffusion films, prism films, micro-porous films, and solar films. The project consists of two phases with a 40,000 air volume RTO in the first phase and a 50,000 air volume RTO in the second phase.

Case 2: A technology company in Guangdong produces transfer paper, transfer film, electrolytic aluminum, polyester film, window film, protective film, etc. The total waste gas volume is 70,000 m3/h, and the equipment achieves standard emissions after completion.

Case 116: A company in Zhuhai produces wet lithium battery separators, and the system has been running smoothly without any faults.

著者宮