Основна информация.

Модел NO.

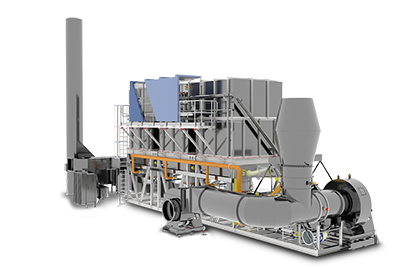

Невероятен RTO

Тип

Инсинератор

Висока ефективност

100

Икономия на енергия

100

Ниска поддръжка

100

Лесна работа

100

Търговска марка

Бямазинг

Транспортен пакет

Зад граница

Спецификация

111

Произход

Китай

Код по ХС

2221111

Описание на продукта

RTO

Регенеративен термичен окислител

В сравнение с традиционното каталитично изгаряне; директен термичен окислител; RTO има предимствата на висока ефективност на отопление; ниски експлоатационни разходи; и способността за третиране на голям поток отпадъчни газове с ниска концентрация.; Когато концентрацията на ЛОС е висока,; може да се реализира вторично рециклиране на топлина; което значително ще намали оперативните разходи.; Тъй като RTO може предварително да загрява отпадъчния газ по нива чрез керамичен акумулатор на топлина; което може да накара отпадъчния газ да бъде напълно нагрят и напукан без мъртъв ъгъл (ефективност на третиране>99%);,;които намаляват NOX в отработения газ,; ако плътността на VOC >1500mg/Nm3,; когато отпадъчният газ достигне зоната на напукване; нагрят е до температура на напукване от топлинен акумулатор; при това условие горелката ще бъде затворена.;

RTO може да бъде разделен на камерен тип и ротационен тип според различния режим на работа.; Ротационен тип RTO има предимства в системното налягане; температурна стабилност,; сума на инвестицията; и т.н

| RTO видове | Ефективност | Промяна на налягането (mmAq); | Размер | (макс.); Третиран обем | |

| Ефективност на лечението | Ефективност на рециклиране на топлина | ||||

| Ротационен тип RTO | 99% | 97% | 0-4 | малък (1 път); | 50000Nm3/h |

| Трикамерен тип RTO | 99% | 97% | 0-10 | Голям (1.;5 пъти); | 100000Nm3/h |

| Двукамерен тип RTO | 95% | 95% | 0-20 | средата (1.;2 пъти); | 100000Nm3/h |

Регенеративен термичен окислител; Регенеративен термичен окислител; Регенеративен термичен окислител; Термичен окислител; Термичен окислител; Термичен окислител; окислител,; окислител,; окислител,; инсинератор,; инсинератор,; инсинератор,; обработка на отпадъчни газове; обработка на отпадъчни газове; обработка на отпадъчни газове; Третиране на ЛОС; Третиране на ЛОС; Третиране на ЛОС; RTO,; RTO,; RTO,; Ротационен RTO,; Ротационен RTO,; Ротационен RTO,; Камера RTO,; Камера RTO,; Камера RTO

Адрес: 8 етаж, E1, сграда Pinwei, път Dishengxi, Yizhuang, ZheJiang, Китай

Тип бизнес: производител/фабрика, търговска компания

Бизнес диапазон: Електротехника и електроника, Индустриално оборудване и компоненти, Машини за производство и обработка, Металургия, Минерали и енергия

Сертифициране на системата за управление: ISO 9001, ISO 14001

Основни продукти: Rto, линия за цветно покритие, линия за поцинковане, въздушен нож, резервни части за производствена линия, машина за нанасяне на покритие, независимо оборудване, ролка за мивки, проект за обновяване, вентилатор

Представяне на компанията: ZheJiang Amazing Science & Technology Co., Ltd е процъфтяваща високотехнологична компания, разположена в зоната за икономическо и технологично развитие на ZheJiang (BDA). Придържайки се към концепцията за реалистични, иновативни, фокусирани и ефективни, нашата компания обслужва главно обработката на отпадъчни газове (ЛОС) промишлеността и металургичното оборудване на Китай и дори на целия свят. Разполагаме с напреднали технологии и богат опит в проекта за третиране на отпадъчни газове с летливи органични съединения, чието позоваване е успешно приложено в индустрията за покрития, каучук, електроника, печат и т.н. Също така имаме години натрупване на технологии в изследването и производството на плоски линия за обработка на стомана и притежава близо 100 примера за приложение.

Нашата компания се фокусира върху проучването, проектирането, производството, инсталирането и пускането в експлоатация на система за третиране на органични отпадъчни газове с ЛОС и проект за обновяване и актуализиране на енергоспестяване и опазване на околната среда на линия за обработка на плоска стомана. Ние можем да предоставим на клиентите цялостни решения за опазване на околната среда, енергоспестяване, подобряване на качеството на продуктите и други аспекти.

Ние също така се занимаваме с различни резервни части и независимо оборудване за линия за цветно покритие, линия за поцинковане, линия за ецване, като валяк, съединител, топлообменник, рекуператор, въздушен нож, вентилатор, заварчик, изравнител на опън, кожен проход, разширителна фуга, срязване, фуги , шевна машина, горелка, лъчиста тръба, редуктор, редуктор и др.

Can regenerative thermal oxidizers handle variable pollutant concentrations?

Regenerative thermal oxidizers (RTOs) are designed to handle variable pollutant concentrations effectively. They are capable of accommodating fluctuations in pollutant concentrations without significant adverse effects on their performance or efficiency. The ability of RTOs to handle variable pollutant concentrations is one of the advantages that make them suitable for a wide range of industrial applications.

Here are some key points to consider regarding the capability of RTOs to handle variable pollutant concentrations:

- High Destruction Efficiency: RTOs are known for their high destruction efficiency, which refers to their ability to effectively destroy or oxidize the pollutants present in the exhaust gases. The combustion chamber within the RTO is designed to maintain a sufficiently high temperature to ensure complete oxidation of the pollutants, regardless of their concentration.

- Retention Time: RTOs are designed with a sufficient residence or retention time within the combustion chamber. This allows the exhaust gases to spend enough time in the high-temperature zone, ensuring that even pollutants with varying concentrations are adequately treated and oxidized.

- Възстановяване на топлина: The heat recovery system in an RTO, typically using ceramic media beds or heat exchangers, plays a crucial role in handling variable pollutant concentrations. The heat recovery system helps maintain the required temperature and provides thermal energy to sustain the combustion process, even during periods of low pollutant concentrations.

- Dynamic Operation: RTOs are designed to operate dynamically, meaning they can adjust their operating parameters to accommodate changes in pollutant concentrations. They can modulate variables such as the flow rates of the exhaust gases and incoming untreated gases, the temperature setpoints, and the switching frequency of the beds to optimize performance under varying pollutant loads.

- Monitoring and Controls: RTOs are equipped with advanced monitoring and control systems that continuously monitor pollutant concentrations, temperature, and other relevant parameters. These systems enable real-time adjustments and optimization of the RTO operation to ensure effective treatment of variable pollutant concentrations.

While RTOs can handle variable pollutant concentrations, it’s important to note that extreme or highly fluctuating pollutant concentrations may require additional considerations. In some cases, pre-treatment methods such as dilution or conditioning of the exhaust gases may be employed to ensure optimal performance of the RTO.

Overall, RTOs are versatile and reliable systems that can effectively handle variable pollutant concentrations, providing efficient and consistent treatment of industrial emissions.

Are regenerative thermal oxidizers suitable for controlling emissions from food processing operations?

Yes, regenerative thermal oxidizers (RTOs) can be suitable for controlling emissions from food processing operations. Food processing operations often generate volatile organic compounds (VOCs) and odorous compounds that need to be controlled to comply with environmental regulations and maintain air quality. Here are some key points regarding the suitability of RTOs for controlling emissions from food processing operations:

- Контрол на емисиите: RTOs are designed to achieve high destruction efficiencies for VOCs and odorous compounds. These pollutants are oxidized within the RTO at high temperatures, typically above 95% efficiency, converting them into carbon dioxide (CO2) and water vapor. This ensures effective control and reduction of emissions from food processing operations.

- Съвместимост на процеса: RTOs can be integrated into the exhaust systems of various food processing operations, capturing and treating the emissions before they are released into the atmosphere. The RTO is typically connected to the process equipment or exhaust stack, allowing the VOC-laden air to pass through the oxidizer for treatment.

- Гъвкавост: RTOs offer flexibility in handling a wide range of operating conditions and pollutants. Food processing operations can vary in terms of flow rates, temperature, and composition of emissions. RTOs are designed to accommodate these variations and provide effective treatment even under fluctuating conditions.

- Odor Control: In addition to VOCs, food processing operations can also generate odorous compounds, which can cause nuisance and odor-related complaints. RTOs can be equipped with additional odor control technologies such as activated carbon beds or scrubbers to address odor concerns and ensure the removal of unpleasant odors.

- Съответствие с разпоредбите: Food processing operations are subject to regulatory requirements for air quality and emissions control. RTOs are capable of achieving the necessary destruction efficiencies and can help food processors comply with environmental regulations. The use of RTOs demonstrates a commitment to sustainable practices and responsible management of air emissions.

It is important to note that the specific design and configuration of the RTO, as well as the characteristics of the food processing emissions, should be considered when implementing an RTO for a specific application. Consulting with experienced engineers or RTO manufacturers can provide valuable insights into the proper sizing, integration, and performance requirements for controlling emissions from food processing operations.

In summary, RTOs are a suitable and effective technology for controlling emissions from food processing operations, providing high destruction efficiencies, compatibility with various processes, flexibility in handling operating conditions, odor control capabilities, and compliance with environmental regulations.

How do regenerative thermal oxidizers handle start-up and shutdown procedures?

Regenerative thermal oxidizers (RTOs) have specific procedures for start-up and shutdown to ensure safe and efficient operation. These procedures are designed to optimize the performance of the RTO and minimize any potential risks. Here is an overview of how RTOs handle start-up and shutdown:

- Start-up Procedure: During start-up, the RTO goes through a series of steps to reach its operating temperature. The start-up procedure typically involves the following stages:

- Purge Stage: The RTO is purged with clean air or an inert gas to remove any potential flammable or explosive gases that may have accumulated during the shutdown period.

- Preheat Stage: The RTO’s heat exchangers are preheated using a burner or an auxiliary heat source. This gradually increases the temperature of the heat exchange media (typically ceramic or metallic beds) and the combustion chamber.

- Heat Soak Stage: Once the heat exchangers reach a certain temperature, the RTO enters the heat soak stage. In this stage, the heat exchangers are fully heated, and the RTO operates in a self-sustaining mode, with the combustion chamber temperature being maintained primarily by the heat released from the oxidation of pollutants in the exhaust gas.

- Normal Operation: After the heat soak stage, the RTO is considered to be in normal operation mode, where it maintains the desired operating temperature and treats the exhaust gas containing pollutants.

- Shutdown Procedure: The shutdown procedure of an RTO is aimed at safely and efficiently stopping the operation of the system. The procedure typically involves the following steps:

- Cool Down: The RTO is gradually cooled down by reducing the flow of the exhaust gas and the supply of combustion air. This helps to prevent thermal stress on the equipment and minimize the risk of fires or other safety hazards.

- Възстановяване на топлина: During the cool-down phase, the RTO may employ heat recovery techniques to capture and utilize the residual heat for other purposes, such as preheating incoming process air or water.

- Purge: Once the RTO has cooled down sufficiently, a purge cycle is initiated to remove any residual gases or contaminants from the system. This helps to ensure a clean and safe environment for maintenance activities or subsequent start-ups.

- Complete Shutdown: After the purge cycle, the RTO is considered to be in a fully shut-down state, and it can remain in this state until the next start-up is initiated.

It is important to note that the specific start-up and shutdown procedures for an RTO may vary depending on the design and manufacturer. Manufacturers typically provide detailed guidelines and instructions for operating their specific RTO models, and it is crucial to follow these guidelines to ensure safe and efficient operation.

editor by CX 2024-03-28